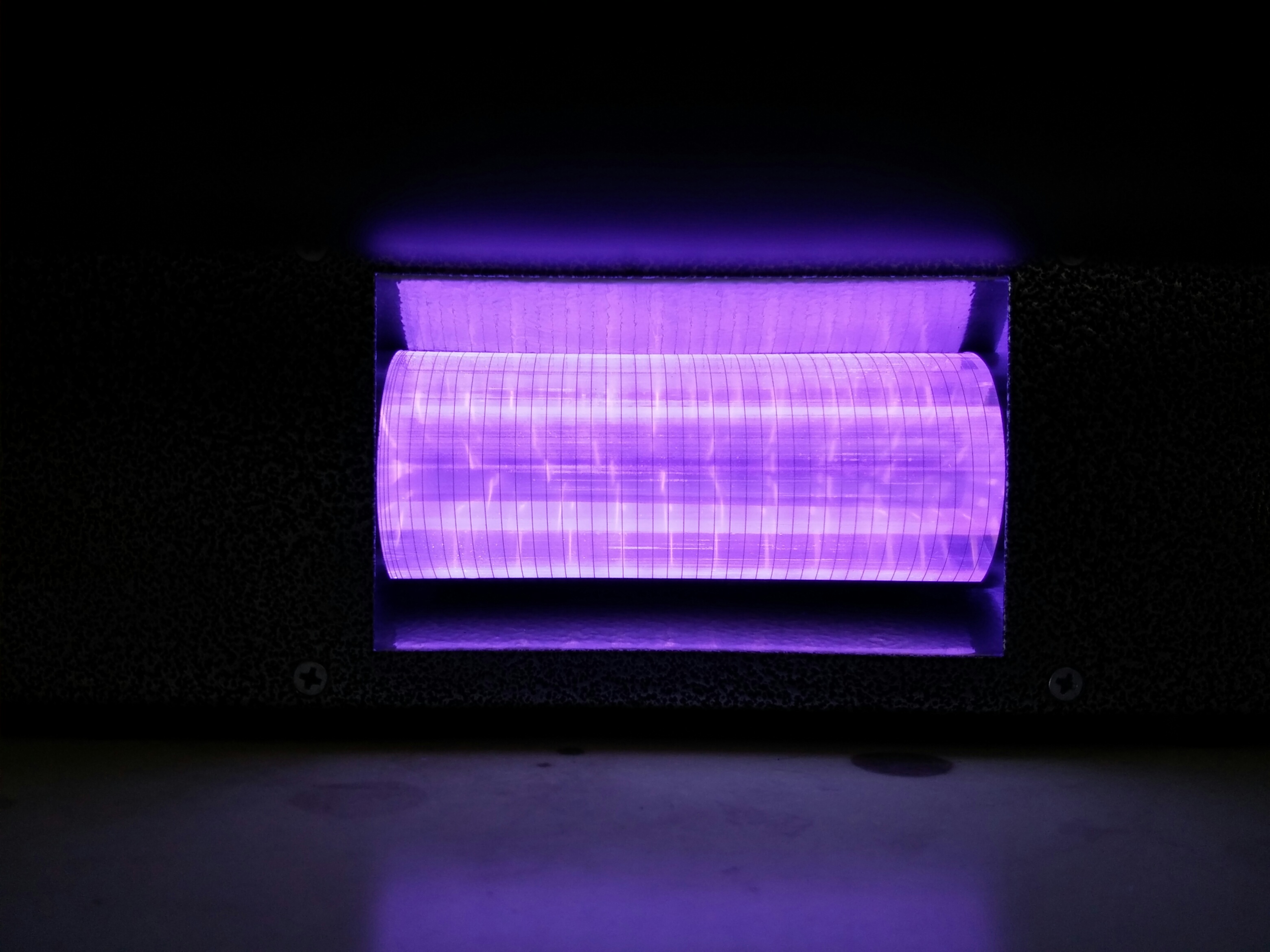

Among other technologies, UV technology is developed and used at Fraunhofer IGB to inactivate viruses, bacteria and spores on a wide range of surfaces in the food, pharmaceutical and medical technology sectors.

UV technologies have the advantage of being dry and free of harmful gases and their degradation products. There is also no temperature stress.

The use of mercury vapor lamps is quite common. These lamps can be used for many purposes with their spectrum mainly in the range of 254 nm. But UV is not all the same: organisms often have different "sensitivity windows" in which they react differently to radiation. This is based on photochemical processes which can damage, for example, RNA or DNA, but also the membrane of bacteria or the viral envelope. The viral envelope not only protects the RNA but also enables it to penetrate host cells in the first place.

Selection of the wavelengths that specifically inactivate the organisms

Living organisms such as bacteria, algae and fungi can (to a limited extent) counteract UV radiation by active repair measures. Bacterial and fungal spores as well as viruses have practically no active repair mechanisms, but they can protect themselves to a certain extent by UV-blocking substances or radical scavengers.

But if the UV wavelength is specifically selected, weak points of the contamination can be specifically "addressed" – for example, by irradiating with high intensity at a wavelength at which no UV-blocking effect is present or by causing damage for which repair mechanisms are not effective. Sometimes, there are some orders of magnitude between the inativation results achieved with unsuitable and appropriate UV irradiation.

Removal of pyrogens

We also use UV lamps to remove residues of killed microorganisms from surfaces. These are the so-called pyrogens: they are dangerous because they can trigger life-threatening sepsis – even though they "only" consist of dead membrane residues.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB