At present, the widespread use of VLPs is limited by the lack of standardized and effcient processes, which, much like a modular construction system, are suitable for producing a variety of different VLPs that can transport specifc loads to various target sites. Moreover, the purifcation steps of such a production process must be developed specifcally for each protein and VLP. Such a process that must be designed empirically and individually is time- and cost-intensive and therefore poses a challenge for production at an industry-scale.

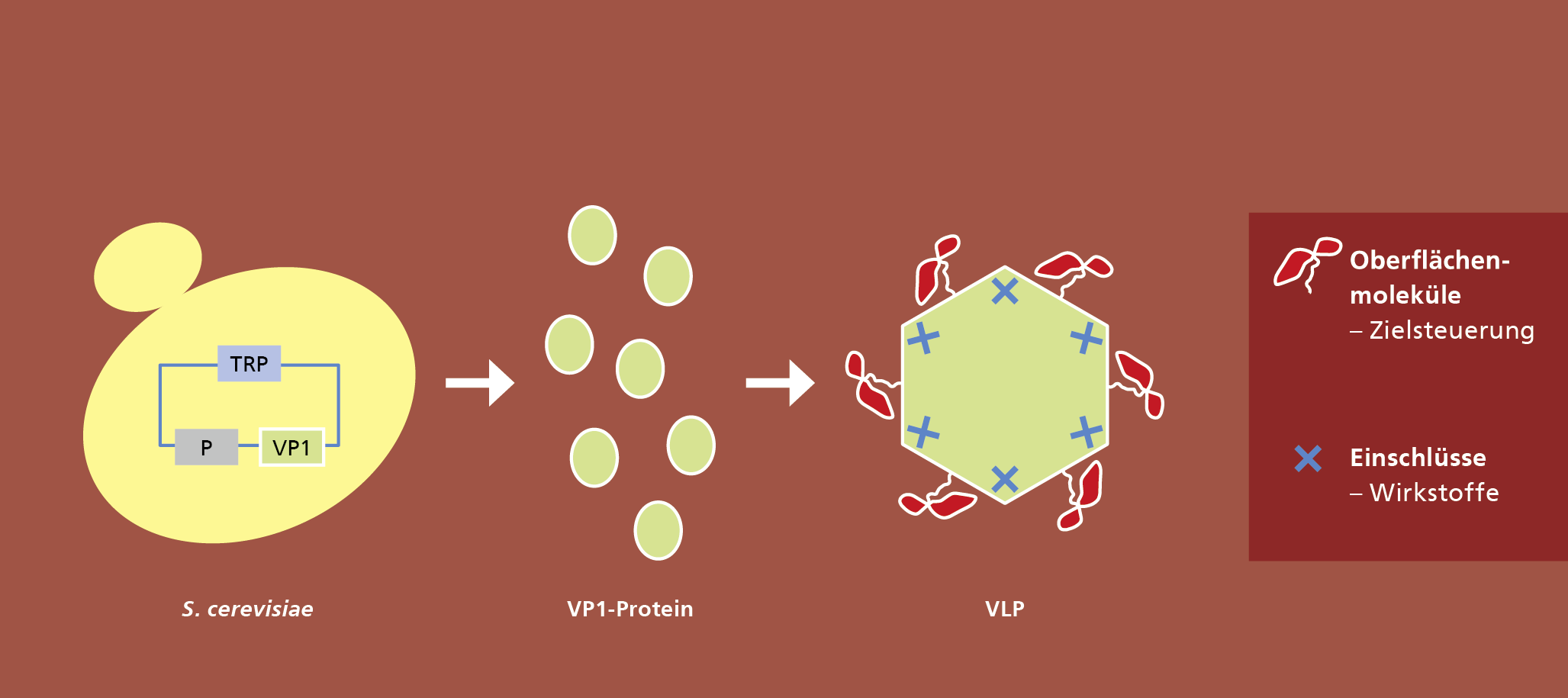

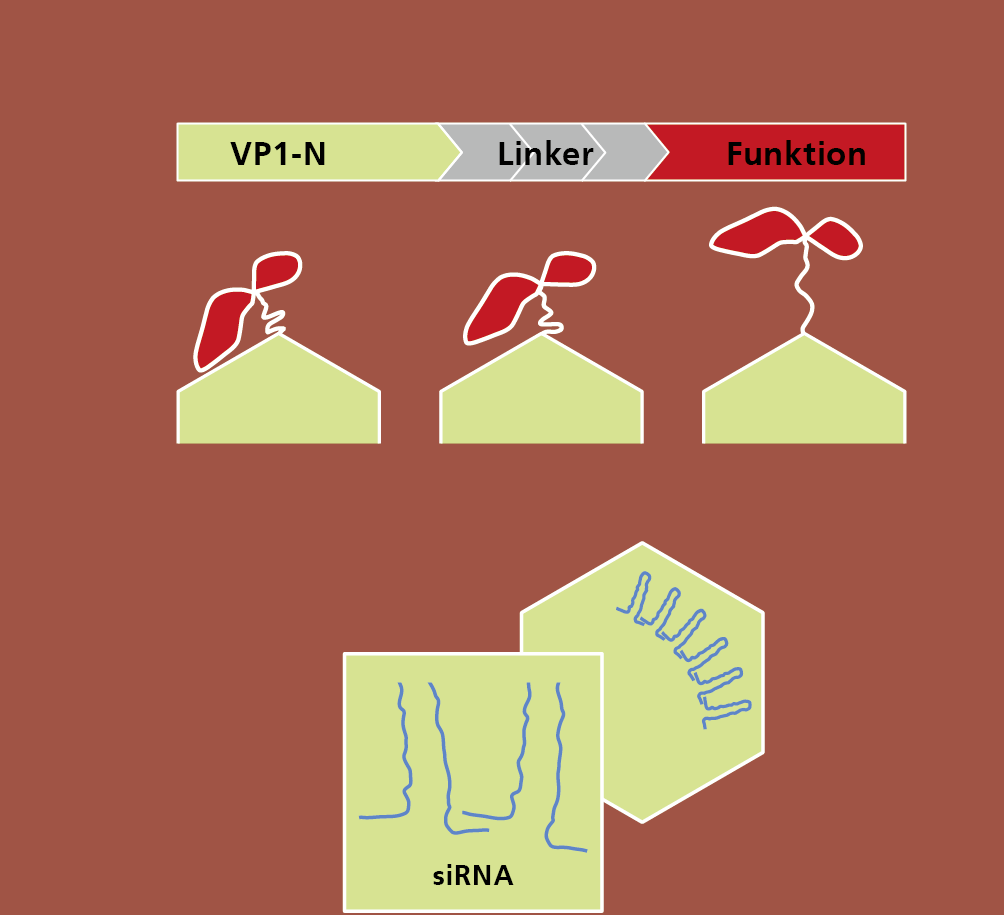

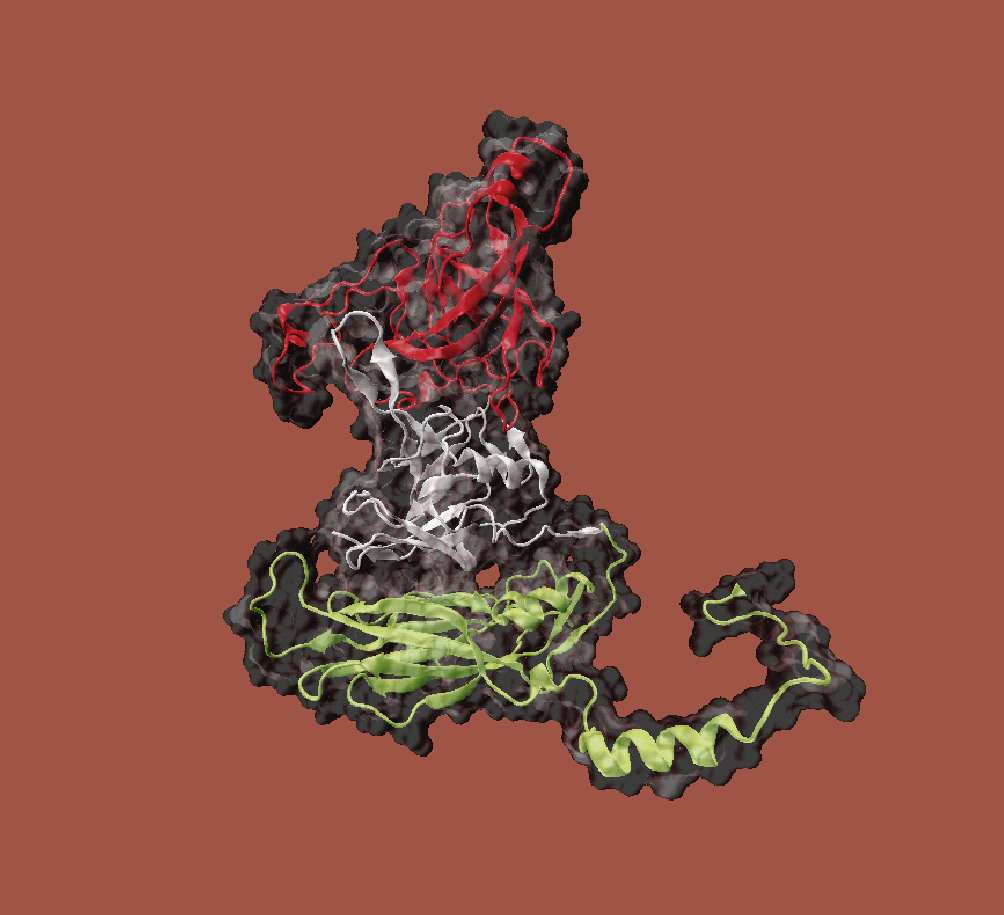

In a new undertaking at the Fraunhofer IGB, we hope to develop a modular system as a platform technology for producing VLPs. A basic module structured with an internal capsule will be incorporated with a functional, variable and complex protein surface that can be used either for targeted control of VLPs (drug delivery) or for the development of vaccines.

For example, antibody fragments or antigens could be used to create a surface that is functional and multivalent. Because the basic module always remains unchanged and only the protein surface is confgured as needed, the production of VLPs, unlike current systems, can be standardized and hence would be reproducible and cost-effective.

Non-enveloped viruses from the Caliciviridae family will be used as the base. We will develop a plasmid that allows the synthesis of the virus proteins – the capsules of these viruses consists of a single type of protein – in the yeast Saccharomyces cerevisiae. This organism has proven to be ideal for protein synthesis for pharmaceutical purposes because it generates few side effects and is cost-effective.

As “proof of principle”, VLPs that conduct active agents specifcally to surface markers of cancer cells via antibodies will be produced.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB