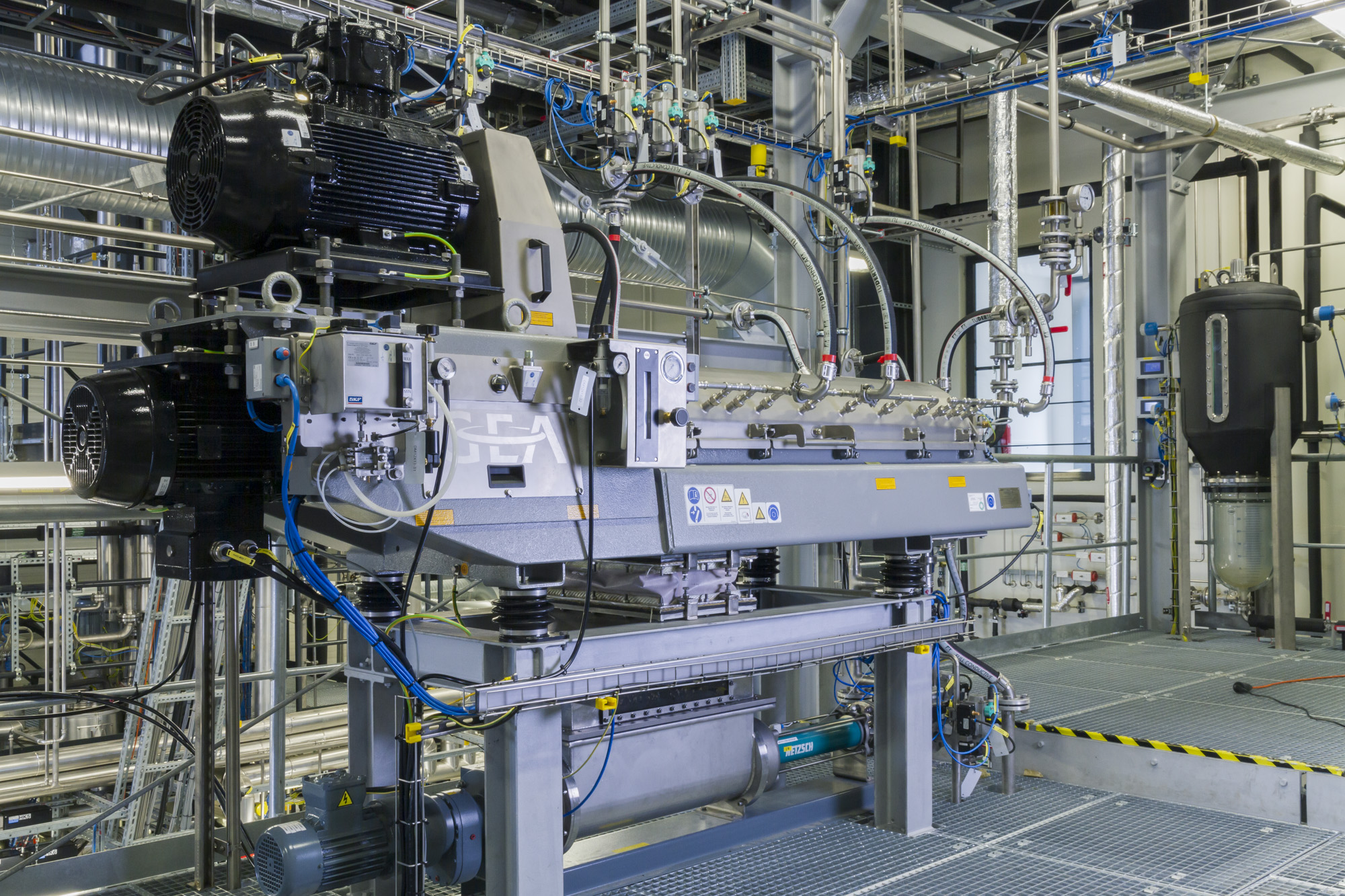

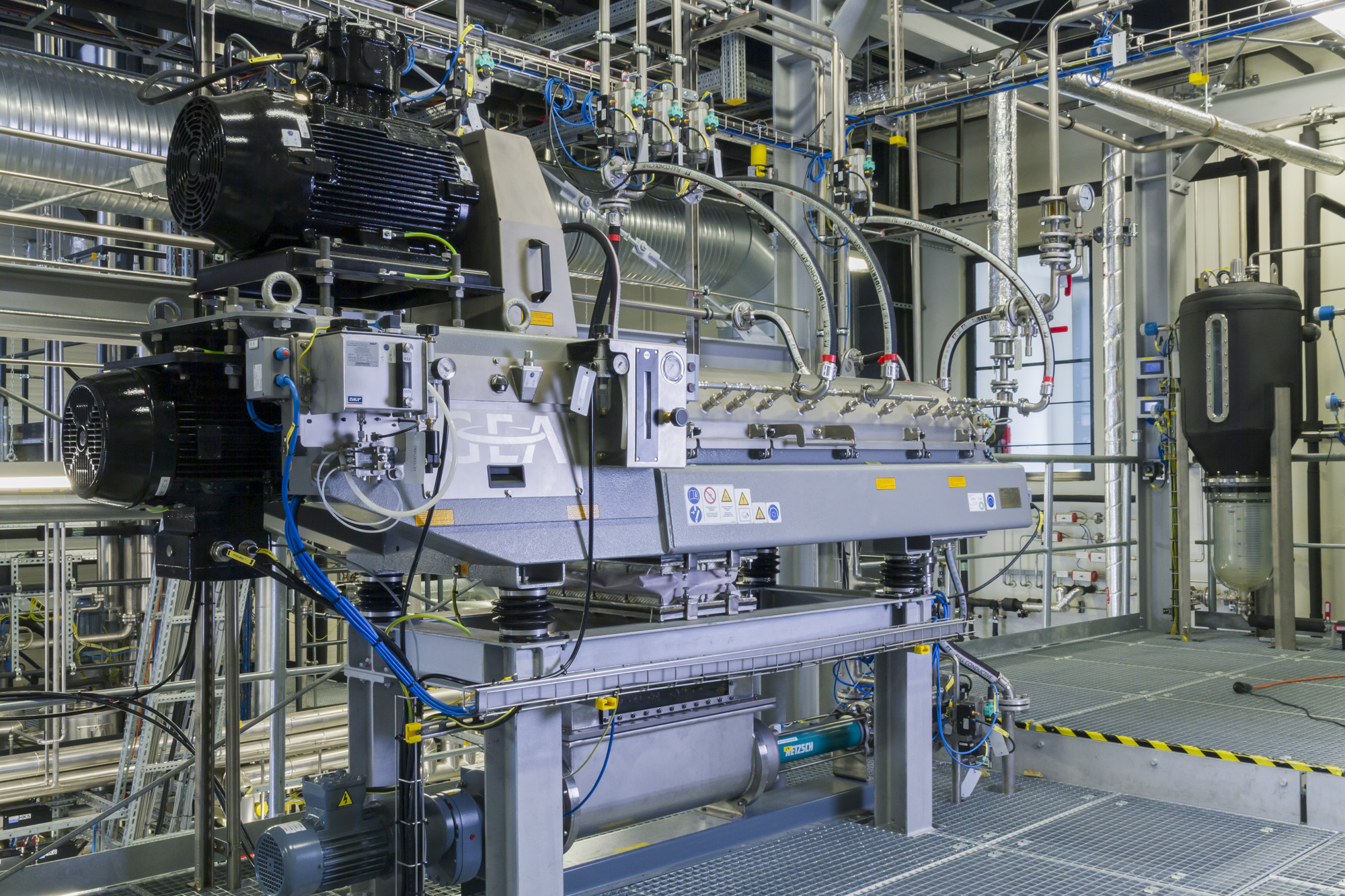

The oilseed biorefinery uses the mild EthaNa process for processing oilseeds, which is performed at ambient pressure and a maximum of 70°C to avoid protein denaturation and other quality-reducing reactions.

Complete utilization of seed ingredients by mild extraction process

In this way, the process enables a holistic utilization of the raw materials and provides product fractions with higher quality compared to conventional industrial processes. In addition to the extraction of high-quality vegetable oils, the processing of protein-rich fractions in particular contributes to the increase in added value.

In addition, a pure hull fraction as well as other valuable molecules are obtained from the oilseeds, which can be used for a wide variety of applications.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP