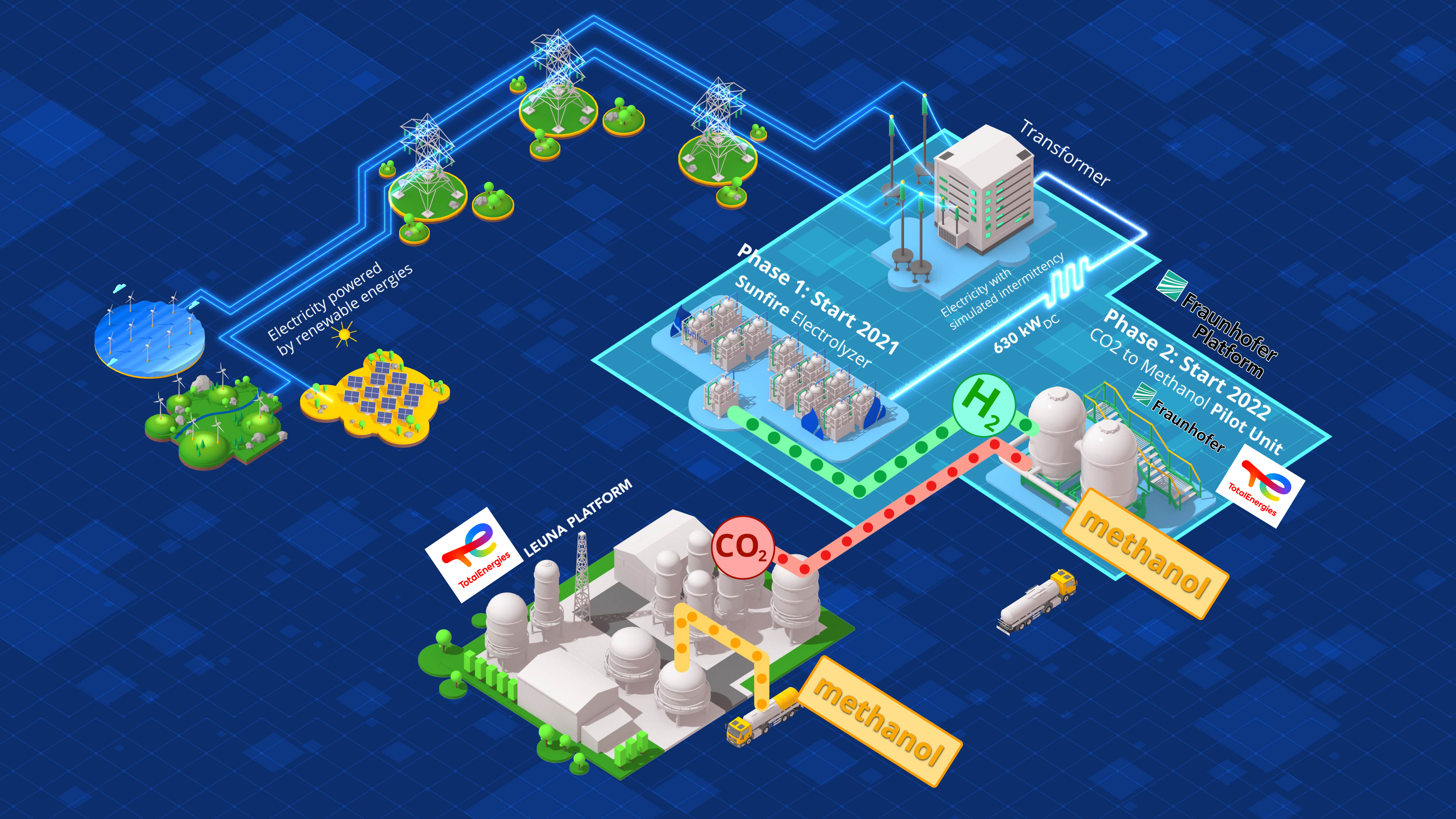

In the e-CO2Met project coordinated by TotalEnergies, methanol is to be produced from regeneratively produced hydrogen and concentrated carbon dioxide. This is an important approach to reducing climate-damaging greenhouse gas emissions. For the conversion of the green hydrogen and CO2, Fraunhofer CBP and TotalEnergies are planning a pilot plant that will be set up in the new Fraunhofer Hydrogen Lab at the Leuna Chemical Park.

E-CO2Met – Electricity & CO2 to Methanol

Challenges and objective

The material use of CO2 and hydrogen from renewable energies offers great opportunities for the global energy and transport transition. Power-to-X projects are thus increasingly coming into focus, as the chemical sector also needs to reduce the greenhouse gas emissions of its processes in the long term. This is precisely what TotalEnergies is pursuing in the e-CO2Met research and development project. As part of this project, CO2 is to be converted into synthetic methanol using regenerative hydrogen in an integrated demonstration plant at the Fraunhofer Hydrogen Lab Leuna, the first large-scale electrolysis test and trial platform in Germany that is fully integrated with the infrastructure of the chemical industry.

High-efficiency electrolysis for hydrogen production from renewable energies

The first step for the synthesis of synthetic methanol from renewable energies and industrial highly concentrated CO2 from a partial waste gas stream of Total Raffinerie Mitteldeutschland GmbH Leuna is the electrolysis of water to hydrogen. For this purpose, project partner Sunfire will develop and provide a megawatt-scale high-temperature solid oxide electrolyzer for use in an industrial environment. The advantage of the high-temperature electrolyzer is the ability to directly use economically generated steam or waste heat from industrial and synthesis processes. The electrolyzer will be operated by Fraunhofer IWES.

For example, Fraunhofer IWES can simulate the intermittency and load profiles of renewable energies, such as photovoltaics or wind energy, in the Hydrogen Lab Leuna. This enables various operational studies to be carried out in close cooperation with Sunfire to evaluate the performance of the system in relation to volatile renewable energy supply, among other things.

Green methanol from renewable hydrogen and exhaust gas CO2

For the chemical conversion of hydrogen to methanol, Fraunhofer CBP will plan, design and build a pilot plant in the Fraunhofer Hydrogen Lab together with TotalEnergies. In this part of the project, the influence of different process parameters as well as the influence of fluctuating feed streams on the methanol synthesis will be investigated together with TotalEnergies.

Multi-purpose plant on Hy2Chem platform

The pilot plant will be designed in such a way that it will be available as a multi-purpose plant for further projects of Fraunhofer CBP after completion of the project. The construction of this pilot plant is the first project that will run within the Hy2Chem platform, which is funded by the state of Saxony-Anhalt through ERDF funds.

Project information

Project title

E-CO2Met – Electricity & CO2 to Methanol

Project duration

April 2021 – December 2024

Project partners

- Fraunhofer CBP, Leuna, Germany

- TotalEnergies, France (Coordination)

- Sunfire GmbH, Dresden, Germany

- Fraunhofer IWES, Leuna, Germany

Funding

The pilot plant for methanol synthesis is financed as a sub-project of E-CO2Met within the framework of the Hy2Chem scaling platform funded by the state of Saxony-Anhalt via ERDF funds. We would like to thank the state of Saxony-Anhalt for funding the "Hy2Chem" project.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP