This field of work focuses on the process-technological development of chemical processes to produce biobased basic, fine and platform chemicals for further processing in the chemical, pharmaceutical or food industries.

In addition to new process concepts, the optimization of the resource and energy efficiency of existing processes also plays an important role here.

Established processes can be adapted and optimized under ecological and economic aspects. In doing this, we not only consider biobased raw materials and carbon dioxide but also examine conventional processes for manufacturing petrochemical products.

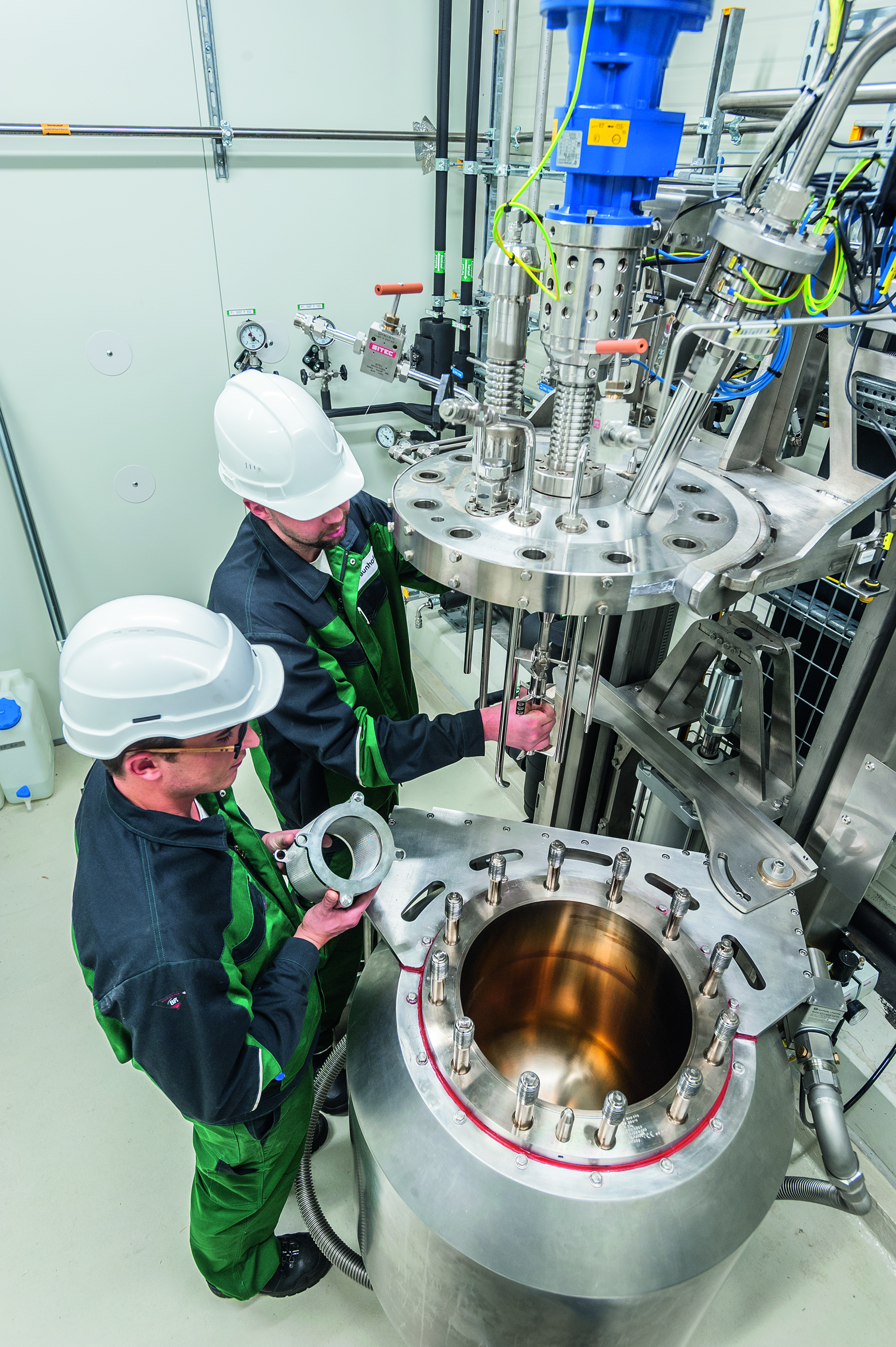

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP