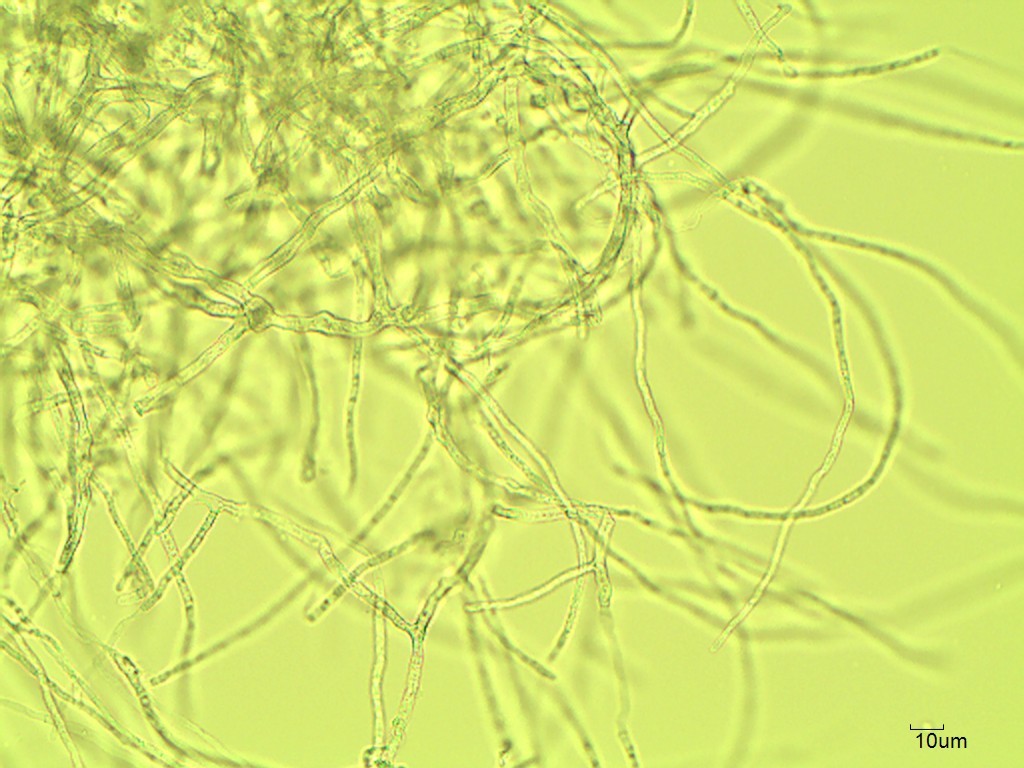

Chemical pulp from organosolv digestion

The basis of the project is the physico‑chemical digestion of wood with alcohol‑water mixtures (organosolv process), making it possible to obtain all three main components of lignocellulose (i.e. cellulose, hemicellulose, and lignin). As an alternative to the production of glucose, the production of fibers and chemical pulp with this process is another economically viable option [1]. However, the investigations by Peter and Höglinger contain considerable potential for optimization, especially with regard to the process conditions during pulping and bleaching. The quality and possible applications of lignin or hemicelluloses were also ignored. Therefore, the Fraunhofer Center for Chemical Biotechnological Processes CBP has adapted the pulping parameters to meet the necessary requirements for yield and purity of cellulose, but also of other products.

Chemical conversion of hemicellulose and lignin

The profitable value added from hemicellulose is still an important prerequisite for the economic viability of a lignocellulose biorefinery, in addition to the utilization of lignin. The German Biomass Research Center (DBFZ) was able to show that a conversion of hemicellulose to biogas is possible with high yields. However, higher‑quality material use is more economically viable. Hydrothermal processes are well-suited for conversion of aqueous systems (the hemicellulose fraction in this case), since water is simultaneously a solvent and a reaction partner in these processes [2, 3, 4]. The aim is to select the conditions so that sugars or furans can be selectively recovered from the hemicellulose fraction. In subsequent processing steps, they can then be separated as starting materials for fermentation or as basic chemicals.

The investigations on the reaction patterns of real hemicellulose fractions carried out at the DBFZ laid the foundations for scaling up to the mini‑plant scale at Fraunhofer CBP. In recent months, process windows were identified for the target products. To increase the value, the organosolv lignins obtained by fractionation is converted into phenol fractions by base‑catalyzed depolymerization, also under hydrothermal conditions. The process established at Fraunhofer CBP is further improved with regard to product selectivity as well as on energy- and material efficiency. In the future, a central issue will be further development of the separation and purification steps, in order to optimize the process with regard to technical feasibility, overall efficiency and profitability.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP