Range of Services and Equipment

Our offer: Process development and scale-up from feedstock to the purfied product

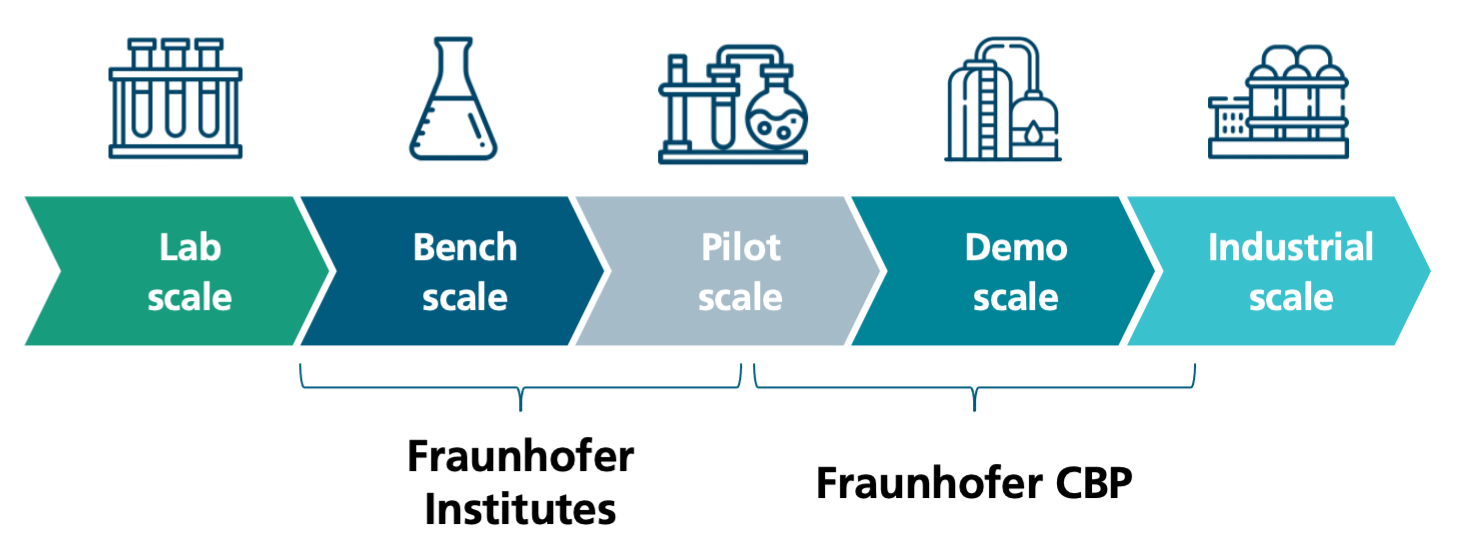

Fraunhofer CBP develops, implements, and optimizes processes, products, and plants all the way to operational and market readiness. Modular reactor and plant technology is available for this purpose. Fraunhofer CBP thus offers a unique, modular platform for mapping complete process chains—from raw material processing and various material conversion processes to product separation and purification.

Your benefit: Faster product development through scaling

With the available technical facilities and the combination of various types of process engineering expertise (biochemical, chemical, mechanical and thermal process engineering) an excellent, time-saving and cost-cutting way of scaling up new technologies is offered especially for small and medium-sized enterprises – with the aim of faster product development and market launch.

How to work with us

Fraunhofer CBP develops, implements and optimizes processes, products and equipment in all the application-relevant fields of expertise in contract for partners from industry and the public sector. Please contact us. We will be happy to explain the possibilities of using our facilities and infrastructure for your development projects and support you in their realization.

In addition, we apply for joint projects – funded by the EU or German Federal Ministries – with the participation of major enterprises, small and medium-sized companies, universities or non-university research establishments. Interested firms and institutes are welcome to get in touch with us for further information and concrete advice.

Our unique selling proposition: Process center as a modular platform

Transferring the manufacturing process to a larger scale is an essential step in bringing new sustainable products to market. With its expertise in scaling up a multitude of processes and its own pilot plants, Fraunhofer CBP supports companies in the market launch of green products offering a wide variety of modules for scaling up new processes. Fraunhofer CBP also offers its expertise and infrastructure for the construction of the customer's own demonstration plants.

Modular processing units

Modular technology platform

On more than 2000 m² of floor space, Fraunhofer CBP offers a unique platform with facilities, technical departments, laboratories and storage space to progress new procedures up to product-related dimensions – from processing raw materials by way of various conversion processes to product separation and purification. To solve process-technical issues, the center provides modular process capacities of up to 10 m³ fermentation volume and continuous plants capable of high-pressure processing up to 20 kg per hour, plus a wide range of processing, treatment and reconditioning techniques and methods.

This versatile “flexible biorefinery” facilitates the conversion of raw materials such as vegetable oils, cellulose, lignocellulose, starch and sugar into chemical products. The aim, according to the biorefinery principle, is the integrated and cascading material-energetic utilization of as many substances as possible obtained from plant biomass as well as the establishment of novel process chains for the material utilization of CO2.

Process development

Processes for manufacturing products from renewable raw materials and CO2

Fraunhofer CBP focuses on developing sustainable processes along the entire value chain for manufacturing products based on renewable raw materials. The aim, according to the biorefinery principle, is the integrated and cascading material-energetic utilization of as many substances as possible obtained from plant biomass as well as the establishment of novel process chains for the material utilization of CO2.

Within the framework of joint projects with partners from industry, universities, and non-university research institutions, we focus on the following areas:

- Production of high-quality extracts from biogenic raw materials and residues

- Lignocellulose pulping, separation, and material utilization of components

- Process development for the production of new technical enzymes

- Production of bio-based alcohols, acids, and olefins through fermentation and chemical processes

- Functionalization of vegetable oils – e.g., biotechnological epoxidation and ω-functionalization

Pilot facilities

Pilot plants and focal points

A total of six pilot plants consisting of flexible unit operations are available for the smooth integration of laboratory protocols, the scale-up and further optimization. Supported by state-of-the-art analytical equipment and process simulation tools, the team of bioprocess engineers, chemists, engineers and technicians is pursuing the following key objectives across a wide range of projects:

- Maximum use of the carbon synthesis potential of nature

- Optimization of the energy and resource efficiency of the processes

- Robust process control and validation of parameters for plant design

- Minimization of waste streams

- Reduction of CO2 emissions

- Use of raw materials that are unsuitable for food or feed production

- Integration of the newly developed processes into existing production networks

Overview on infrastructure and technical equipment

- Pulping and component separation of lignocellulose using organic solvents, with a capacity of 1 metric ton of biomass per week

- Fermentation capacities of 10/100/300/1000 and 10,000 liters, equipment for downstream processing of fermentation products

- Reactors for enzymatic processes up to 1000 liters

- Various process units for chemical reactions unter ATEX conditions (continuous up to 20 kg/h or batch up to 100 liters at temperatures up to 500°C and pressures up to 300 bar)

- Mechanical and thermal separation processes (including high-temperature rectificatioin up to 350°C at reduced pressures and extraction with l-propane and sc-CO2), also under ATEX conditions

Overview of equipment

Overview of our plants

Our equipment quartet: Learn more about our plants

Get to know our plants quickly and easily using meaningful parameters. Our Fraunhofer CBP quartet cards provide the most important key figures:

- Nominal volume

- Throughput

- Pressure range

- Temperature range

- Special features and areas of application

Please contact us for further information!

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP