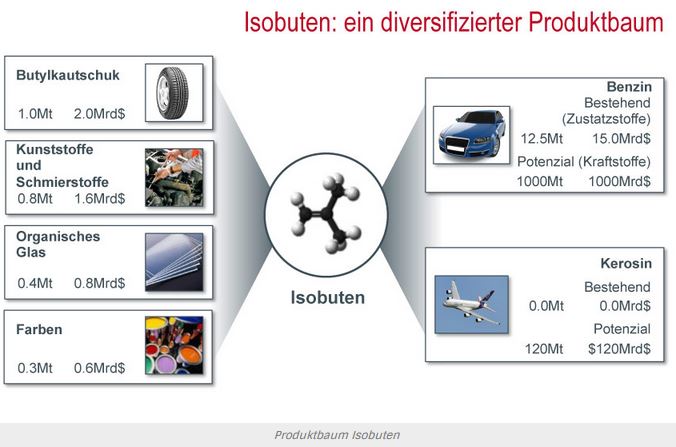

Isobutene is currently commercially obtained exclusively from fossil sources, mainly petroleum. Isobutene is an important platform chemical for the production of transparent polymers, butyl rubber and, above all, fuel additives. The process studied in this project allows for the first time the production of isobutene from renewable raw materials. Furthermore, it is possible to use isobutene for the production of isooctane, which is a main component of gasoline fuels. In fact the octane rating is one of the key performance measures of gasoline fuels. A cost‑effective, bio based production process for isobutene therefore makes it possible to produce fuel additives, which both reduce the emission of fossil CO2 and improve the quality of the fuel.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP