Enzymatically optimized organosolv fractionation with integrated enzyme production

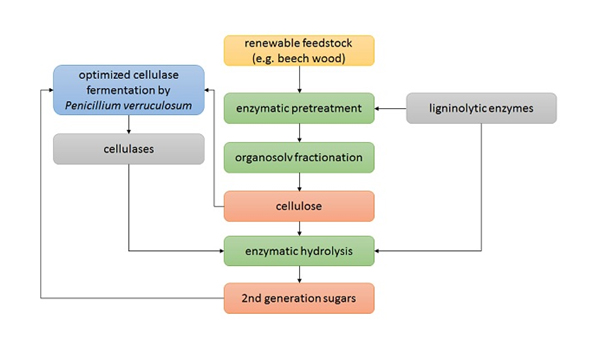

The goal of this project is to design an integrated process for the production of second generation sugars using ligninolytic enzymes and novel cellulases. Basis for this is the organosolv process of Fraunhofer CBP, which is already established in pilot scale. The enzyme production will be integrated into the overall sugar production by using fractions originated from the organosolv process as fermentation substrates. The primary feedstock used in this project is beech wood. The overall process will be demonstrated in pilot scale.

The innovative idea of this project lies in the combined application of cellulases and ligninolytic enzymes (LE) in 2G sugar production. In the plant cell wall, lignin crosslinks different polysaccharides and fills the spaces between cellulose and hemicellulose fibers. This increases the stability of the cell wall and makes the carbohydrates less accessible for digestion. The application of LEs before and during the wood fractionation process will disrupt the lignin network around the fibers. This potentially leads to a reduced consumption of energy and chemicals, by using less severe conditions in the pretreatment process. In the hydrolysis step we propose to apply cellulases and LEs simultaneously to the resulting fibers. This will lower inhibitory effects of lignin on cellulase and will likely lead to higher yields of fermentable sugars, to a lower necessary cellulase concentrations and a faster reaction.

Another aspect of this project is the use of novel cellulases and hemicellulases from Penicillium verruculosum, which are relatively tolerant towards cellulase inhibitors. P. verruculosum cellulases are not yet available on the market and are characterized by an increased level of β‑glucosidase. β‑glucosidases are more effective in splitting smaller oligomers such as cellobiose, which leads to higher sugar yields. Since the amount of cellulolytic enzymes produced by P. verruculosum is presently lower than produced by other hosts, we further aim to improve our production strain genetically.

Scale‑up of cellulase production to 1 m³ scale

The fermentation process was developed in cooperation with the Saxon Institute for Applied Biotechnology (SIAB). After the successful establishment of cellulase fermentation on the 40 L scale at SIAB, the scaling at Fraunhofer CBP up to 1 m³ was carried out. The sterile, batchwise addition of cellulose as a solid material and its mixing represented the greatest challenges. By increasing the scale a comparable productivity could be achieved. It was also shown that the cellulase produced is very well suited for the enzymatic hydrolysis of beech wood cellulose. In addition, a higher sugar yield of approx. 25 percent compared to commercially available cellulases (CTec 2) was demonstrated.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP