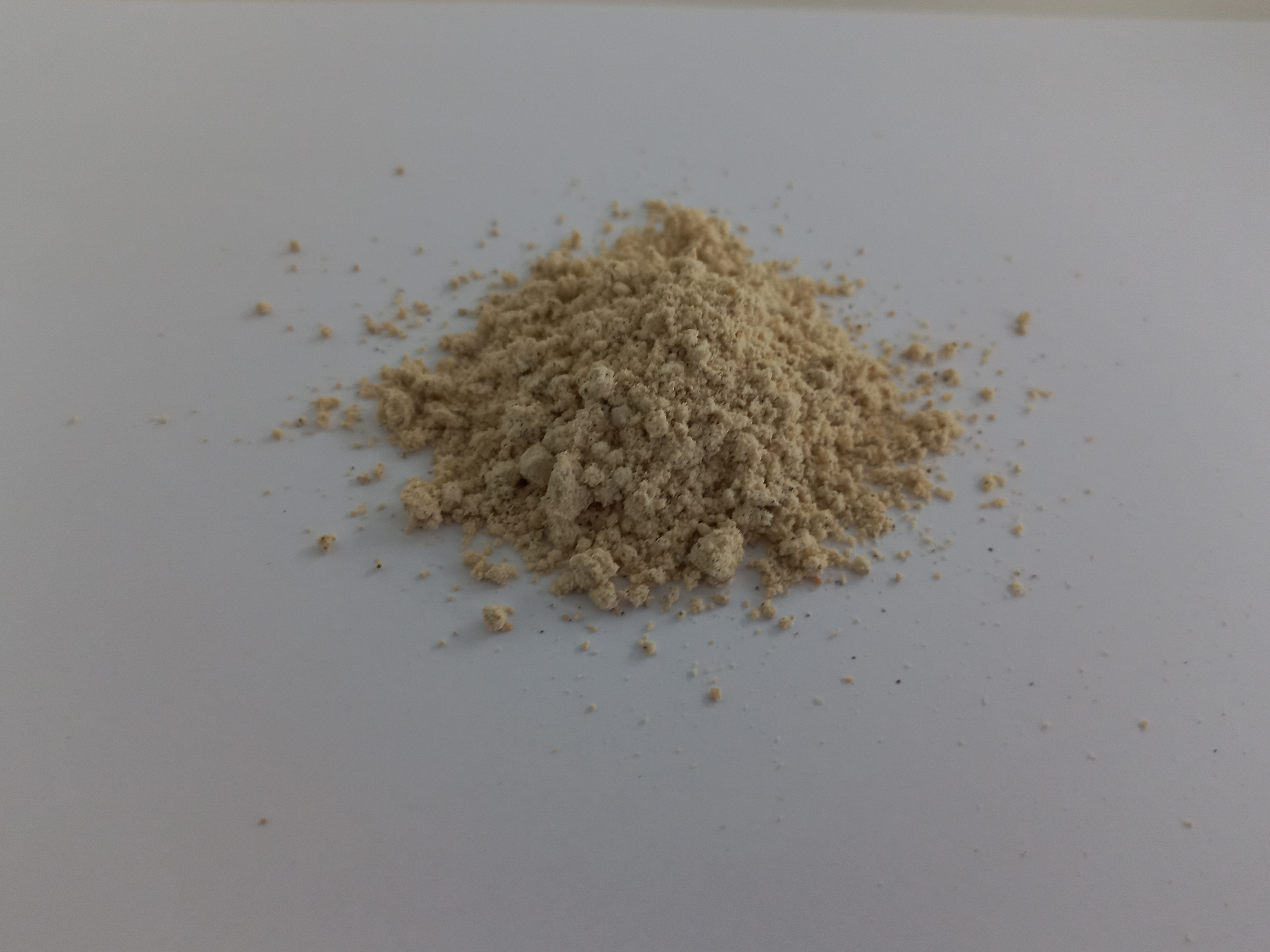

In the “Napf – new high-protein rapeseed feed” project, the EthaNa process is being optimized on a pilot scale to produce high-quality rapeseed kernel concentrate (RKC) for animal feed in sufficient quantities. The economic viability and suitability of RKC are being evaluated in feed technology tests.

Napf – New Protein-rich Rapeseed Feed

Scaling up an innovative process concept for processing rapeseed for the production of sustainable feed mixtures and their use in animal nutrition

Challenges

Rapeseed processing for animal feed production faces the challenge of reducing the dependency on soy, which often comes from non-regional and genetically modified sources. Traditional rapeseed processing methods use hexane as a solvent, raising health and environmental concerns. Furthermore, these processes often result in suboptimal utilization of many of the valuable rapeseed components. Therefore, there is an urgent need for innovative, sustainable processes that maximize the added value of domestic rapeseed.

Objectives and project plan

The project “New Protein-Rich Rapeseed Feed – Napf” aims to scale up and optimize innovative rapeseed processing with the EthaNa process. This process uses ethanol as an environmentally friendly solvent and enables the production of a high-quality rapeseed kernel concentrate (RKC) with a high protein content and low fiber content. The focus is on reducing the use of soy in feed mixtures and strengthening domestic rapeseed production. In addition to validating the process on a pilot scale, the digestibility and acceptance of RKC in animal nutrition will also be investigated in order to produce marketable and sustainable feed.

Impact

The establishment of the EthaNa process will significantly increase the added value of rapeseed and reduce the dependency on soy imports, which will have a positive impact on the environment. The use of ethanol as an environmentally friendly solvent also reduces the carbon footprint of rapeseed processing.

The project promotes sustainable animal nutrition by advancing the development of demand-orientated feed. The newly obtained RKC offers promising applications, particularly in poultry feeding, and can also be used in other areas of animal nutrition. In the long term, the process opens up international marketing opportunities, contributing to job creation and strengthening the competitiveness of the German feed industry.

Publications

As part of the project “New high-protein rapeseed feed – Napf”, a poster was presented at Proteina 2023 and a lecture was held at the ble Innovation Days. The focus was on the EthaNa process, in which RKK is obtained by means of mild ethanolic extraction of hulled rapeseed. The gentle process conditions (maximum 70°C) preserve the structure of the rapeseed proteins in the RKC. Bitter substances are removed by separating the hulls, while fatty acids and phosphorus-containing components are dissolved in the ethanol, which also results in a rapeseed oil in pre-refined quality as a co-product. The protein-rich RKC is promising for animal nutrition and contributes to reducing the use of soy in animal feed production.

- Hartmann, R.; Verges, M.; Steffler, F.; Junghans, U. (2023). Die EthaNa®-Anlage – Erhöhung der stofflichen Wertschöpfung des Rapses. Proteina’23.

- Hartmann, R. (2024). Skalierung neuer Verfahren zur nachhaltigen Produktion proteinreicher Rapsfuttermittel. Innovationstage. 2024.

Project information

Project title

New protein-rich rapeseed feed (Napf) – Scaling up an innovative process concept for processing rapeseed for the production of sustainable feed mixtures and their use in animal nutrition

Project duration

April 2023 – March 2026

Cooperation partners

- Fraunhofer Center for Chemical-Biotechnological Processes CBP, Leuna (Coordination)

- University of Hohenheim, Stuttgart

- B+B engineering GmbH, Magdeburg

- Raiffeisen Kraftfutterwerk Kehl GmbH

- Cargill GmbH, Salzgitter

Funding

We would like to thank the German Federal Ministry of Food and Agriculture (BMEL) for funding the project “New protein-rich rapeseed feed – Napf”, promotional reference 281C703A21, in the Innovation promotion program.

Fraunhofer Center for Chemical-Biotechnological Processes CBP

Fraunhofer Center for Chemical-Biotechnological Processes CBP