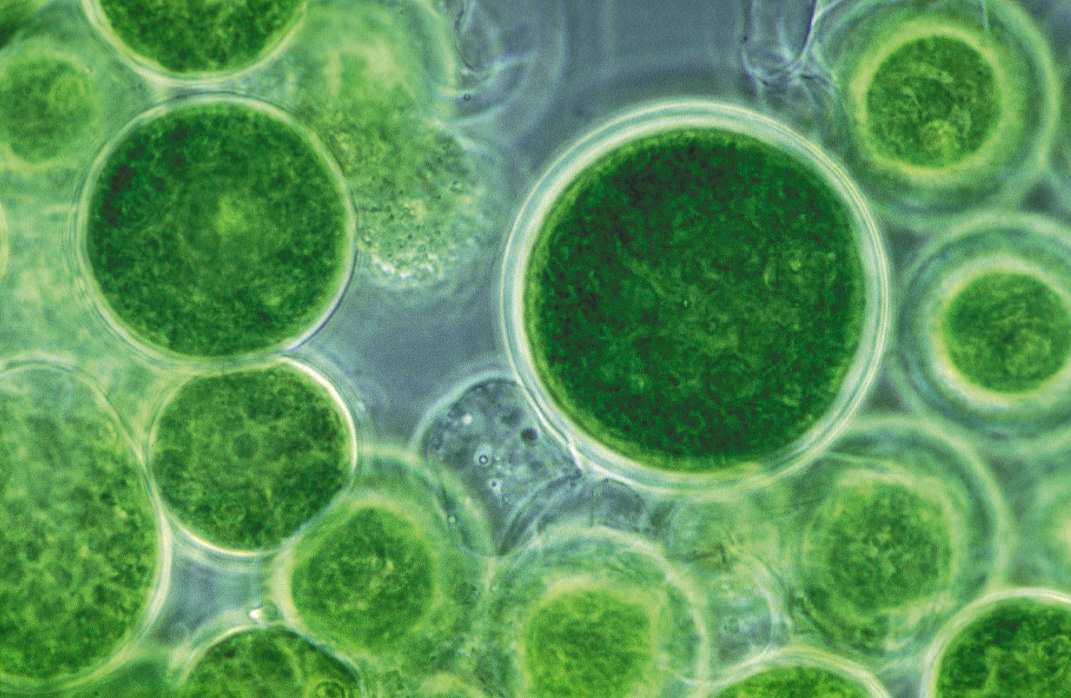

Biological systems consist of individual or a large number of cells that multiply through metabolisms and processes organized in control loops and interact in complex structured networks. The understanding of these intracellular (metabolism) as well as extracellular (cell differentiation in the organism) control and regulation mechanisms is an essential tool for the development of effective microorganisms, not only for the production of enzymes or biopolymers, but also for the development of drugs that balance disturbed cellular control and regulation mechanisms. Examples of this are the administration of insulin for diabetes or highly individualized therapies such as CAR-T cell therapy for tumor diseases.

From recognition at molecular level...

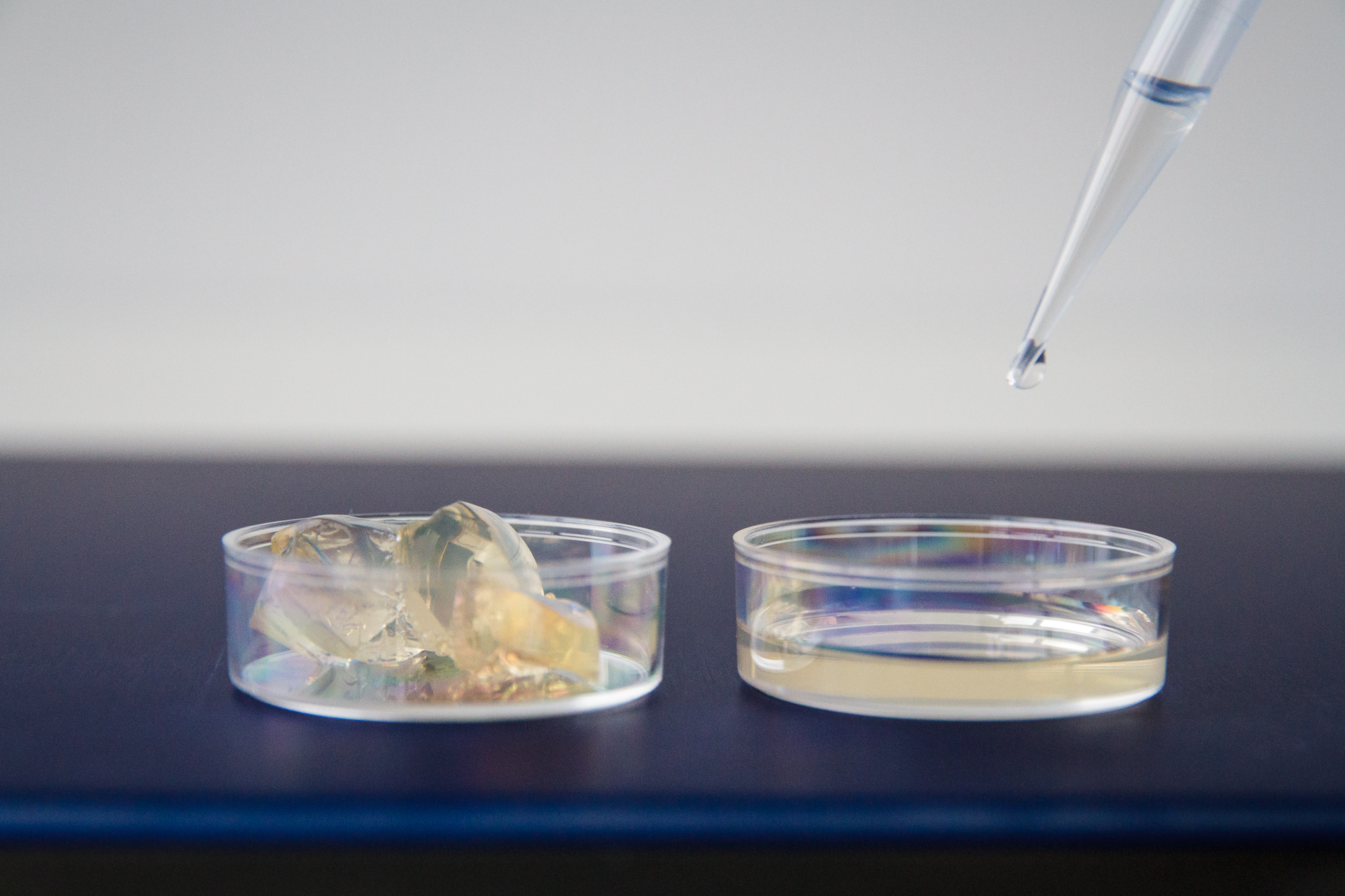

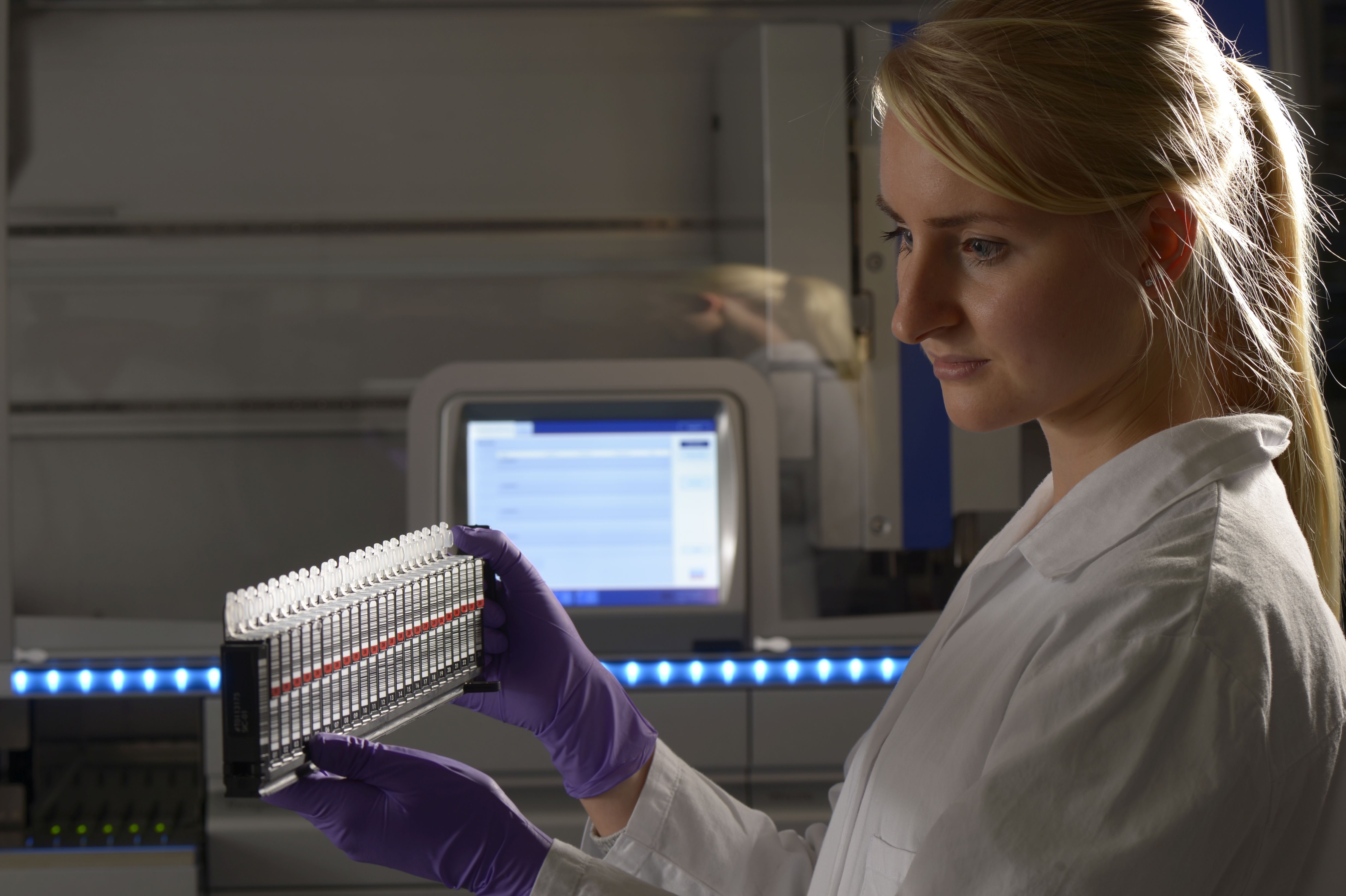

Among other things, IGB contributes to the decoding of these networks and control mechanisms by developing and applying innovative methods in the field of high-throughput sequencing (Next-generation sequencing). IGB is therefore laying the foundation for the identification of biomarkers for the personalized diagnosis of various diseases, for the molecular analysis of infection processes or for the characterization of microorganisms for industrial biotechnology. Furthermore, the Institute uses this technology to capture complex microbial metagenomes and transcriptomes for diagnostics as well as for environmental biotechnology. Based on these findings, new production organisms for biobased chemicals or pollutant-degrading microorganisms are identified and subsequently optimized using molecular biological methods.

...to material conversion with bioprocess engineering

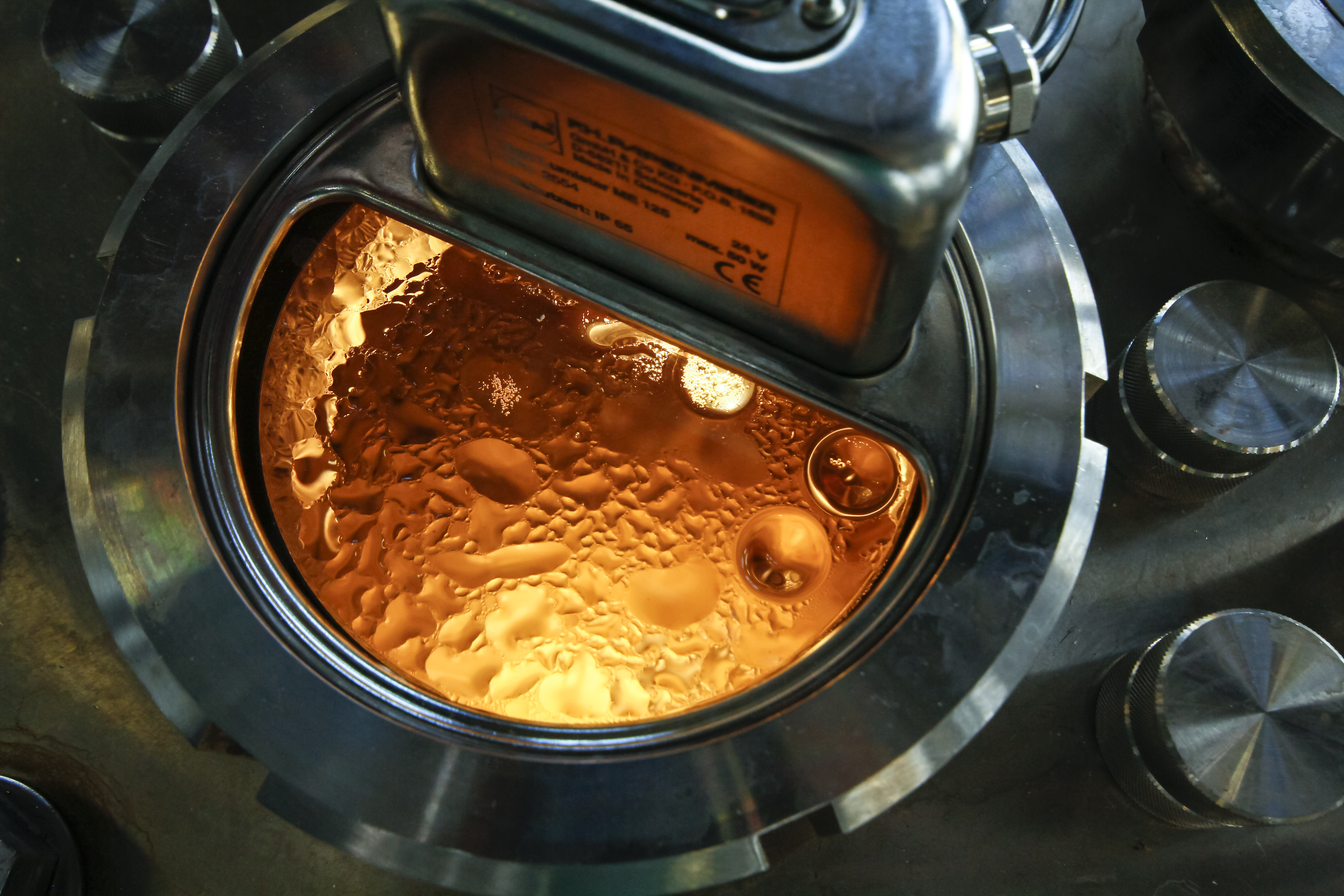

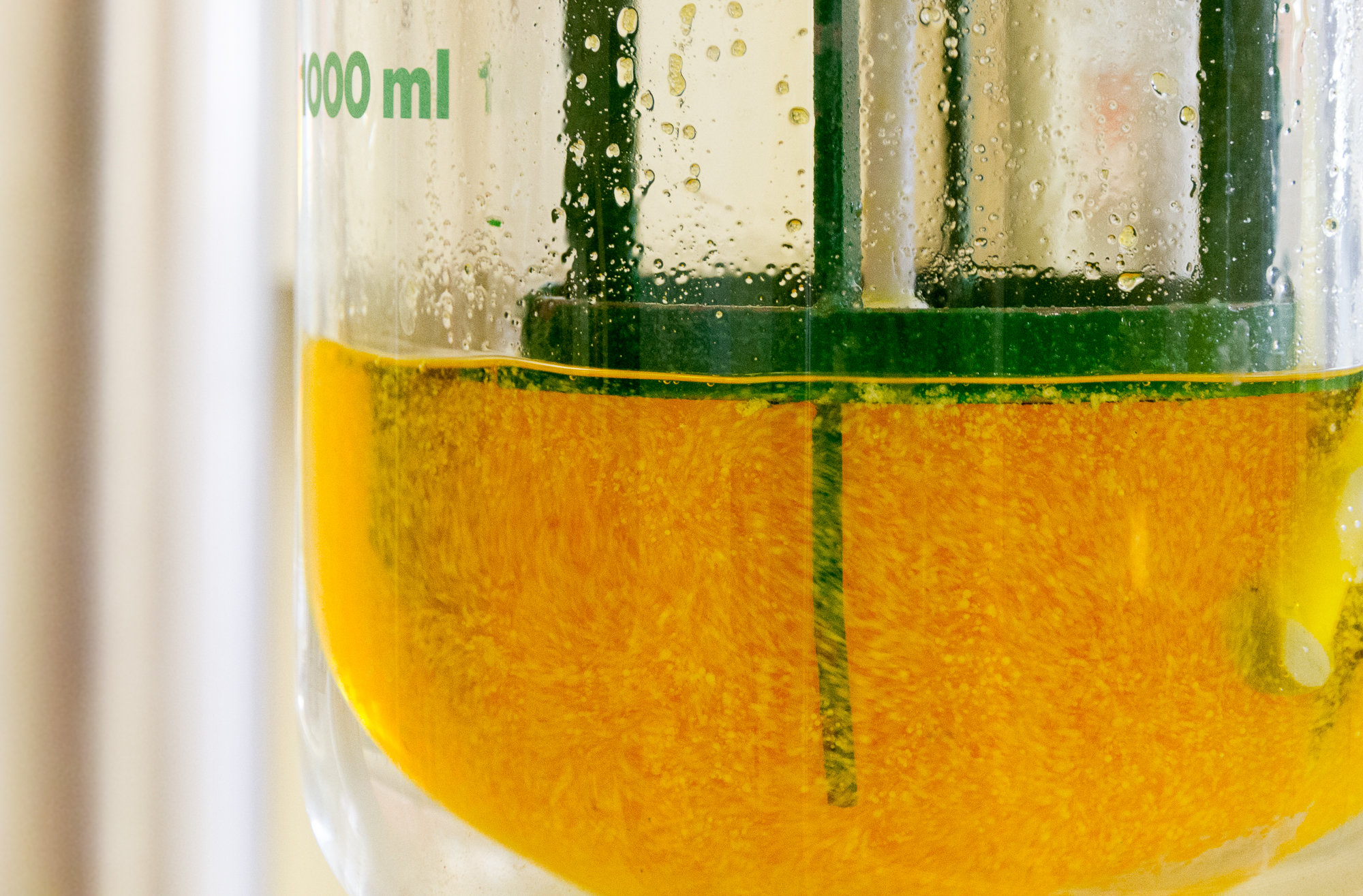

As a further core element of biological transformation, bioprocess engineering deals with the development, modelling, operation and scaling of biotechnological processes in order to implement them in industrial practice. On the one hand, the optimal cultivation conditions for the targeted build-up of products or degradation of pollutants by the organisms must be set. In addition to material conversion, IGB also integrates the appropriate digestion, extraction or purification procedures into the process. In this context, our aim is to achieve maximum material and energy efficiency as well as product quality throughout the entire process chain.

We therefore also develop specific reactor systems for the various tasks, for example membrane reactors for immobilizing enzymes or bioreactor systems, with which the hydraulic residence time can be decoupled from the biomass residence time and thus the space-time yield can be increased.

The complex control mechanisms inside and outside the cells also require comprehensive measurement and control technology for the entire system. The integration of artificial intelligence into these systems will enable both process intensification and accelerated adaptation to rapidly changing conditions.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB