Membranes for water purification

Membranes are now widely used in the purification of water. In particular, filtration membranes (micro-, ultra-, nanofiltration) are used to separate different particles (bacteria, viruses) and substances by size exclusion. Fraunhofer IGB is working on the development of new, green manufacturing processes for filtration membranes (Green Membranes).

In filtration, the pressure to be applied increases with decreasing pore size and thus the energy input increases considerably. We are therefore developing membrane adsorbers to retain even smaller molecules by adsorption such as micropollutants at low pressures (Micropollutants).

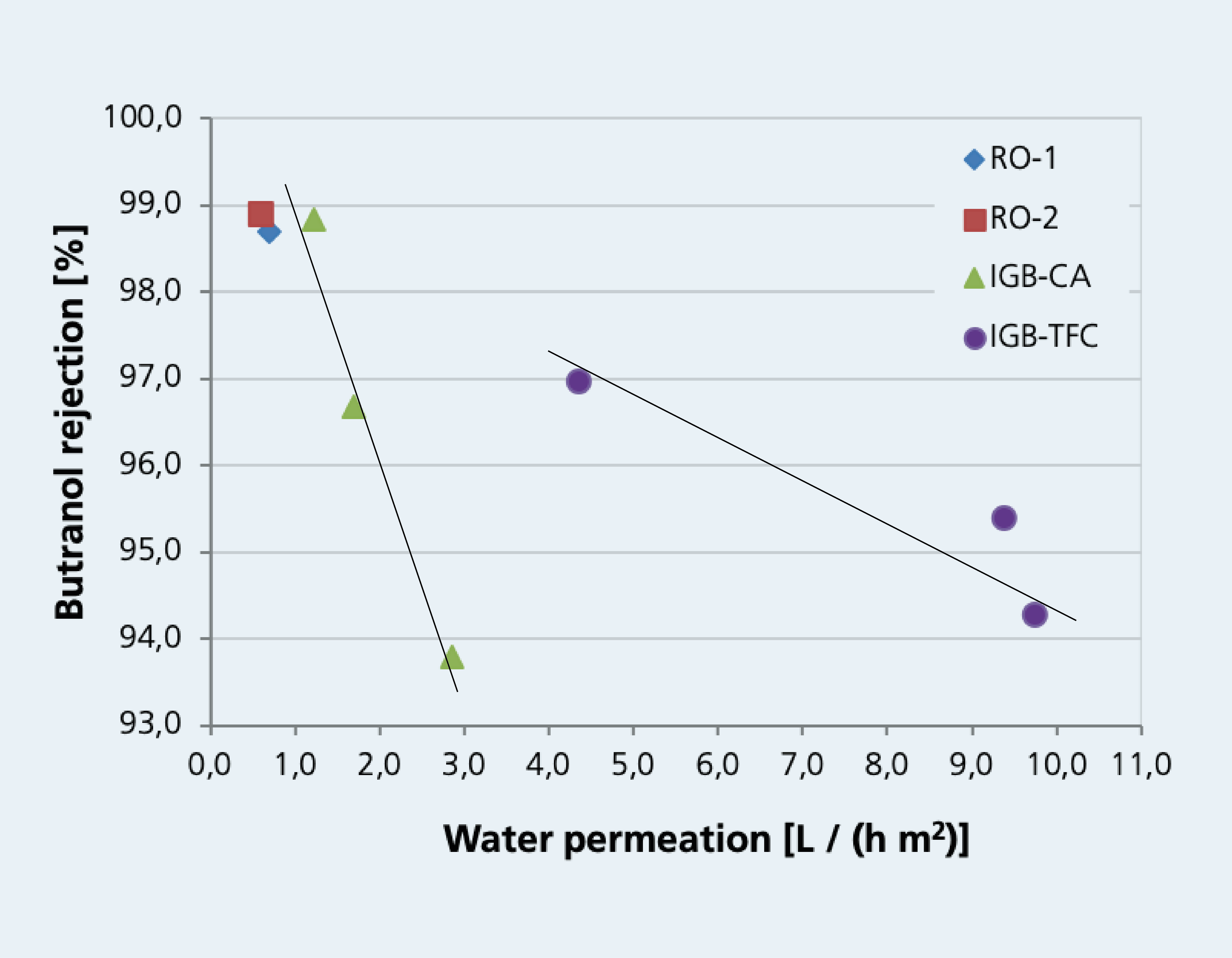

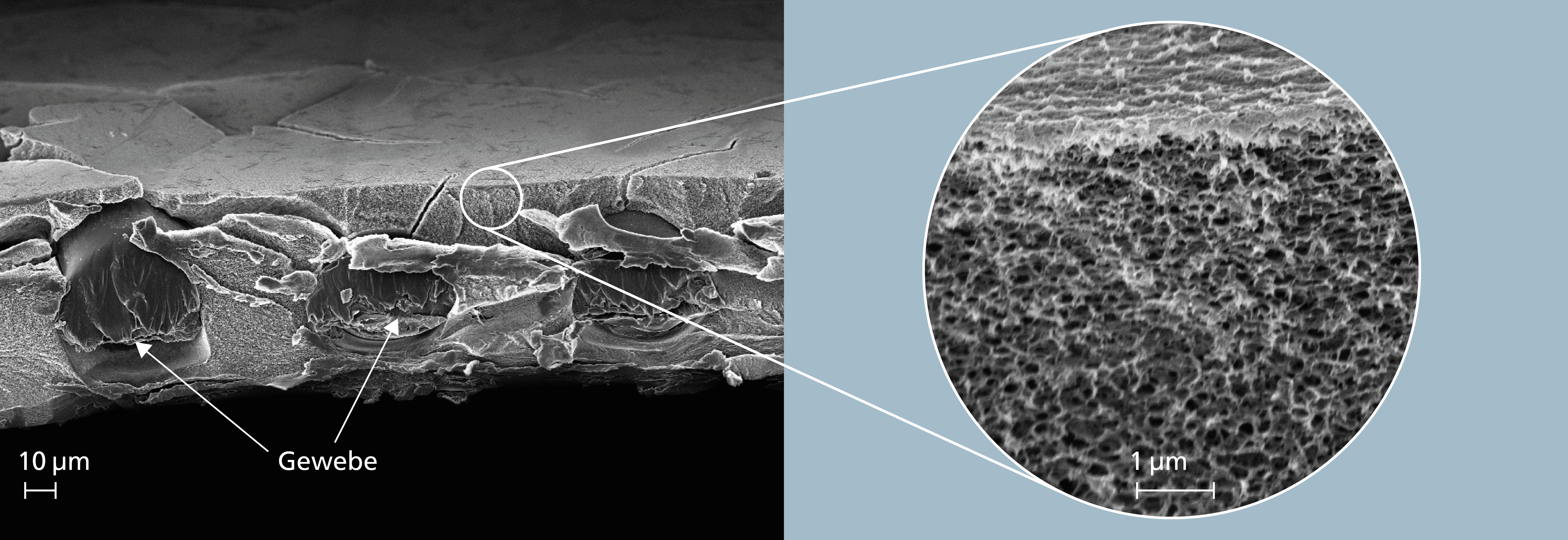

Reverse osmosis (RO) now also plays the most important role in the desalination of seawater. Thin-film composite (TFC) membranes produced by interfacial polymerization, which are permeable to water but retain salts, are used for this purpose. Pressures higher than the osmotic pressure of the solution to be desalinated must be used.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB