Improved comfort due to surface modification

Fraunhofer IGB has developed a process in cooperation with Hecht Contactlinsen GmbH to modify the surface of contact lenses with the aim of achieving improved comfort. The surfaces are modified in such a way that an almost closed film of lachrymal fluid can form. At the same time the formation of protein-containing deposits which can cause clouding in lenses is reduced. However, it is essential that the positive properties of the bulk material of the contact lens, particularly the oxygen permeability and the optical properties are retained.

Hydrophilization of lenses by means of plasma technology

Due to the thermal instability of the material low-pressure plasma processes are particularly suited for surface modifications. Hydrophilic functions are systematically built into the surface of the lens by means of suitable process control. They improve the wettability of the surface and reduce the formation of protein deposits due to an increased adsorption of water in the boundary-layer.

A series of tests with different gases and gas mixtures, excitation frequencies (microwave / radio frequency), treatment times and power inputs was conducted to determine the optimal plasma parameters.

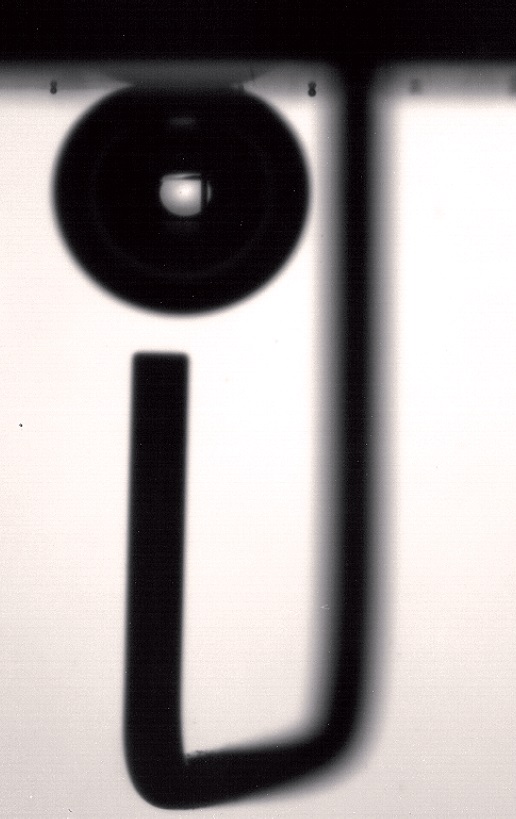

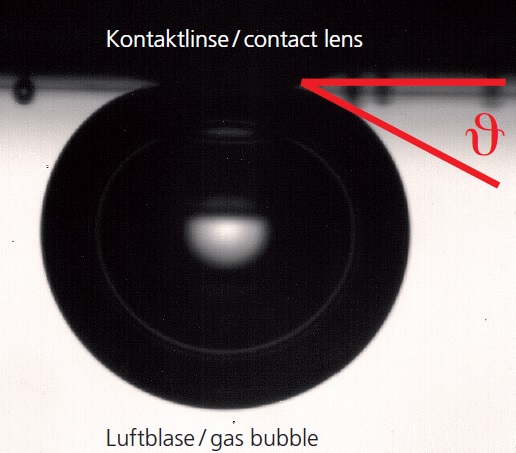

Adapted analysis methods produce findings on wettability and protein deposits under test conditions which are as realistic as possible. In order to evaluate the wettability, for instance, the modified contact lenses were stored in simulated tears and the wetting angle was determined by dosing an air bubble on the surface.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB