Requirements for biomass and production process

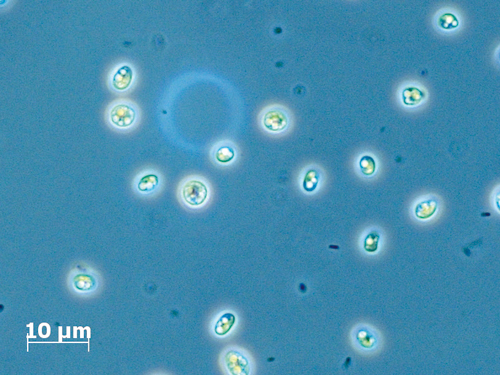

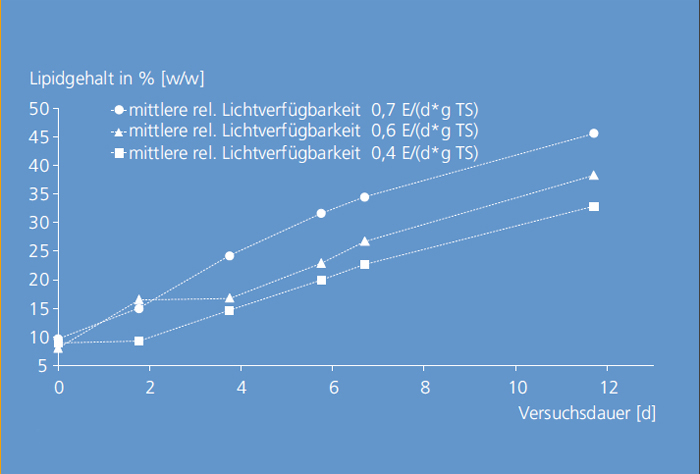

A high lipid content is a prerequisite for the economic use and efficient processing of the algae biomass. Furthermore, the fatty acid spectrum should have a high proportion of saturated and monounsaturated fatty acids, as polyunsaturated fatty acids reduce the storage stability of the algae oil. The accumulation of fatty acids in the form of triglycerides can be induced by nitrogen limitation of the microalgae culture. The triglycerides are stored as storage molecules inside the cell (see picture). In laboratory experiments at the Fraunhofer IGB we were able to achieve lipid contents of up to 70 percent [w/w] under permanent artificial lighting.

For the production of algae biomass for energetic use, it is necessary to transfer this process to the field using sunlight. The challenge here is to establish a process that is stable even under varying conditions in the field and generates biomass with a high lipid content. This is because the given day-night rhythm and changing weather conditions result in fluctuating process conditions.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB