The use of superheated steam drying (SHSD) at atmospheric pressure has many advantages over conventional methods with hot air.

The oxygen content in the process atmosphere is low, thus preventing oxidation processes affecting the product and thereby contributing towards maintaining product quality. Degradation of valuable constituents, such as vitamins, is also prevented.

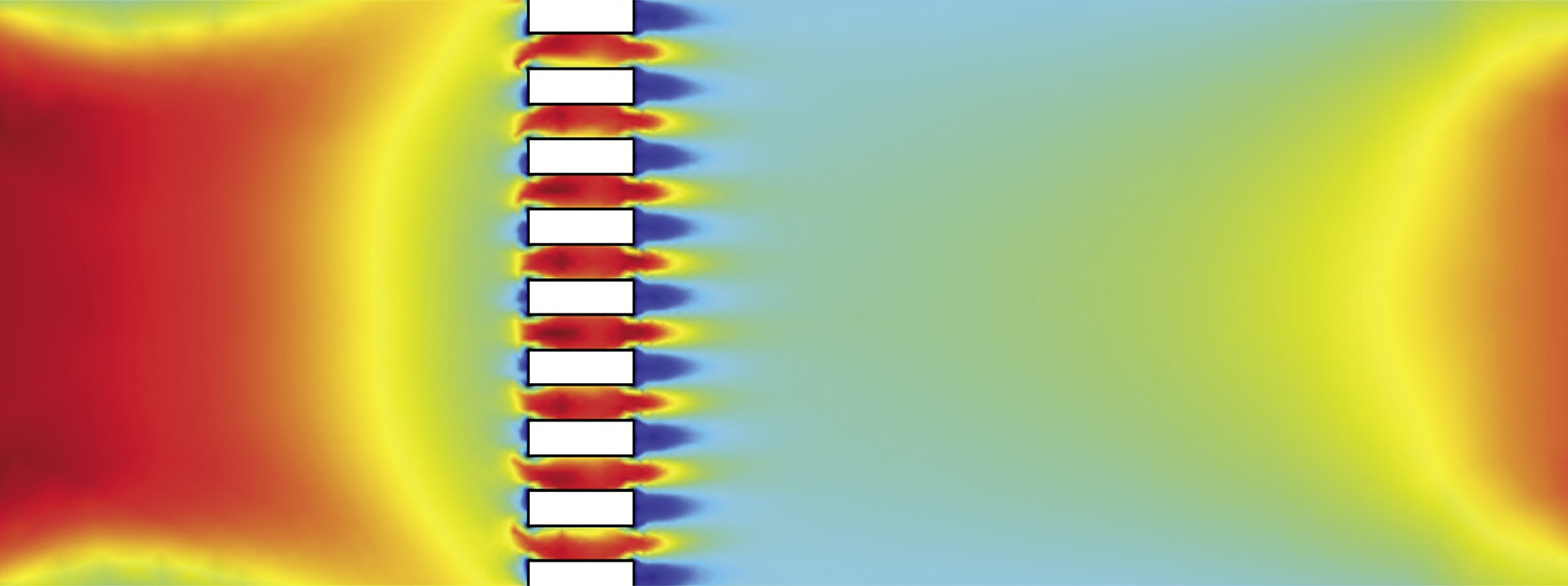

The thermodynamic properties of the drying medium (water vapor) allow more intensive heat and mass transfer during the drying process. This means that shorter residence times are achieved than with conventional drying methods, resulting in less damage to the products through thermal degradation during the drying process. The product quality is thereby enhanced. However, the high drying gradient can cause undesirable changes to the structure of the material. This risk can be addressed by volumetric preheating of the product with microwaves.

Furthermore, food products contain components in their material matrix that become volatile at significantly lower temperatures than the drying temperature of approx. 120–150 °C. These compounds must be removed using exhaust air treatment in conventional drying plants. Thanks to the partially open reactor concept in SHSD, these compounds are collected together with the excess vapor and can be separated selectively and recovered as recyclable material. This means that these highly valuable compounds are not lost, but can make a significant contribution towards covering the costs of the drying process step.

The semi-open plant concept allows all conveyor techniques to be used, thus permitting the most suitable technique to be used for the food product.

The plants can be designed compact and energy-efficient due to the more rapid drying process.

Furthermore, the absence of atmospheric oxygen reduces the risk of explosion, resulting in a significantly simpler construction and operation.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB