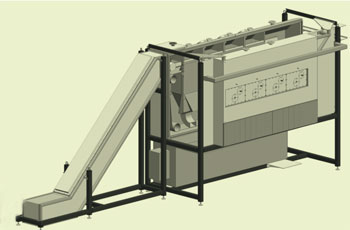

In the EcoBug project, the drying of the digested manure and cyanobacteria was carried out with a novel superheated steam dryer (SHSD). This dryer offers significant advantages in comparison with common hot air dryers.

Due to the superior heat transfer of steam, higher drying rates are achievable with SHSD at the same temperature. This leads to a lower specific energy consumption of

0.75–0.90 kW·h/kg water removed for SHSD compared to 1.10–1.70 kW·h/kg water removed in a comparable hot air dryer[1].

Moreover, higher thermal conductivity and heat capacity of superheated steam compared with hot air results in enhanced heat transfer to microorganisms, enabling pasteurization and/or sterilization. As superheated steam is recirculated and reheated in a closed loop, an excess of evaporated water develops which is carried off along with NH3 and volatile organic carbon (VOC) from SHSD. In our approach VOCs and NH3 are condensed out with the excess steam enabling condensable valuable organic substances including volatile fatty acids (VFA) and NH3 to be recovered. This eliminates the environmental problem of VOC and NH3 emissions in conventional hot air dryers.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB