Chitosan in the textile industry

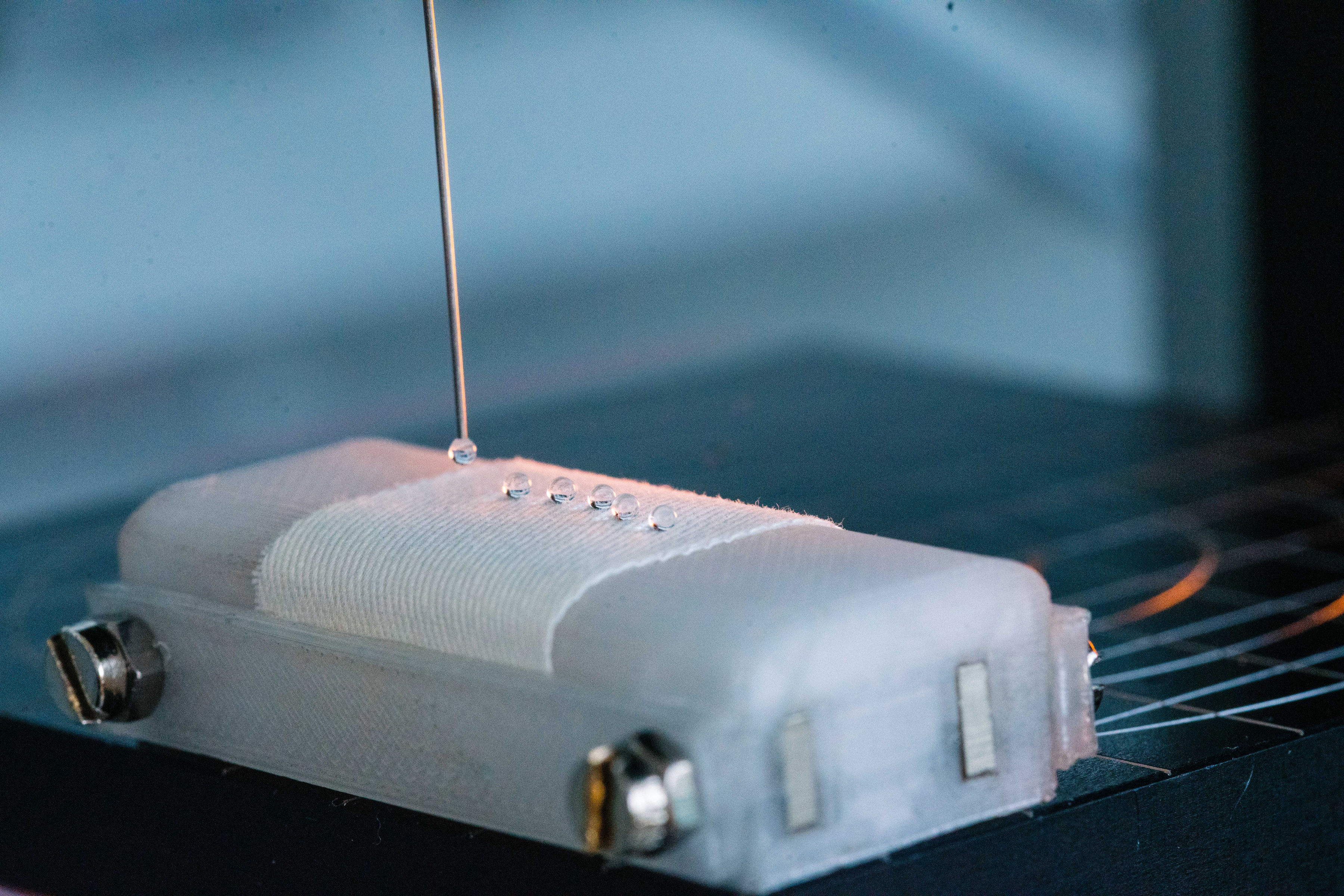

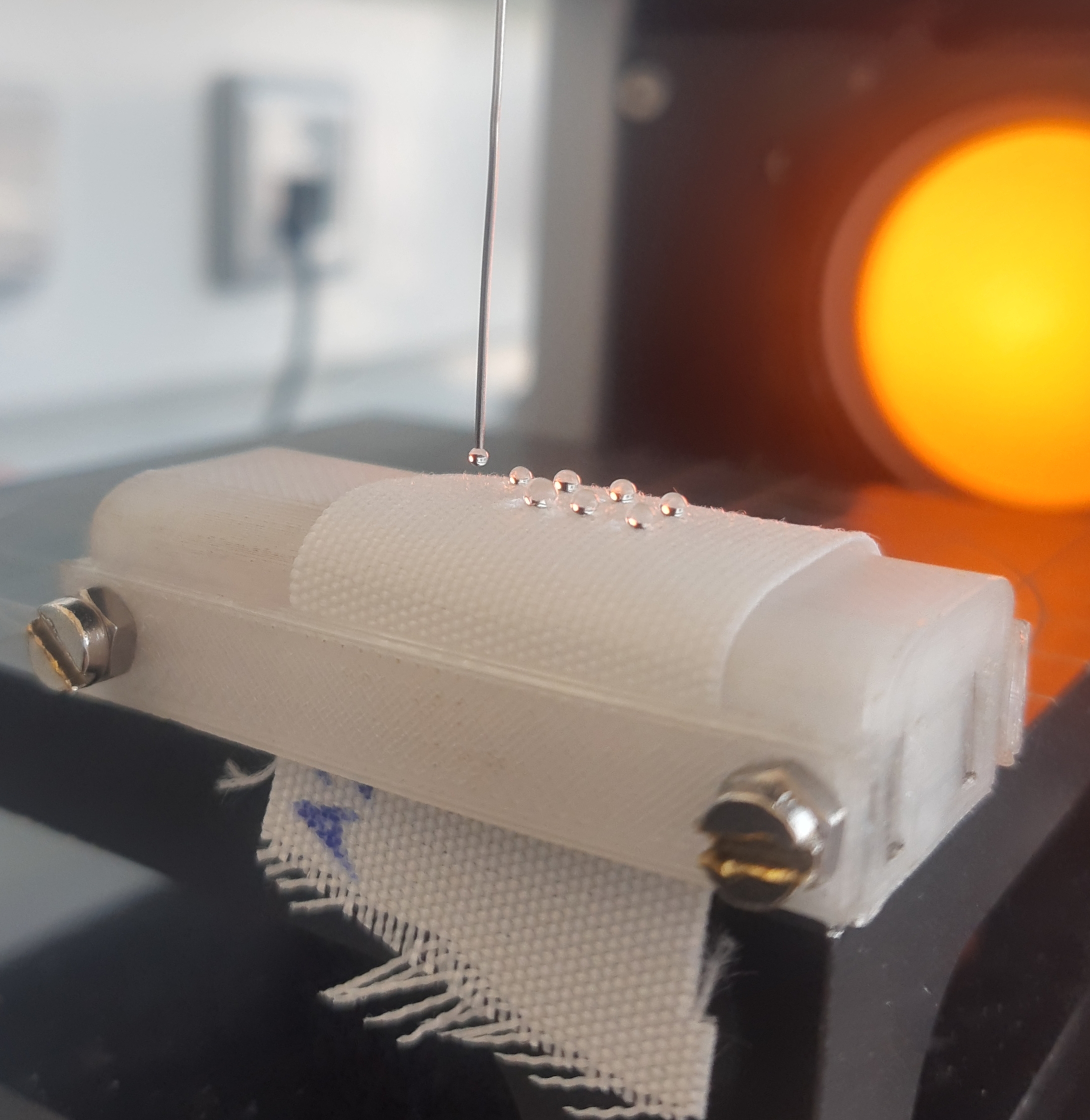

Chitosan, which can be obtained as a residue from insect breeding, industrial fermentation or fishery waste, is already being used in the textile industry as a biobased and environmentally-friendly sizing agent. Due to its chemical structure – with binding points for further functionalities – the renewable biopolymer is also suitable for sustainable refinement and fluorine-free hydrophobic treatment of cotton, polyester and blended fabrics.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB