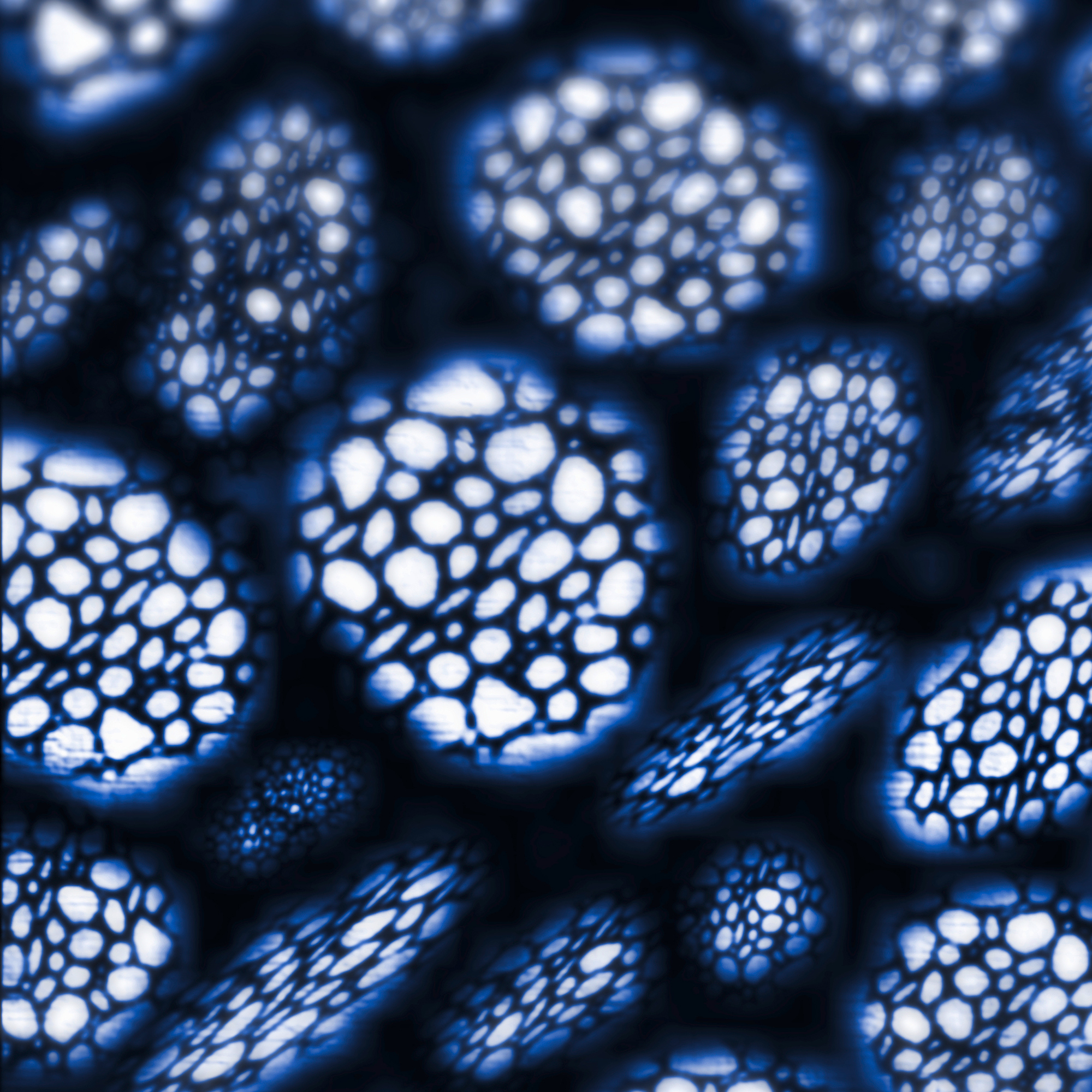

Algae, bacteria and yeast contain a vast repository of biochemicals with high economic value. However, recovering these biochemicals involves expensive downstream processing (DSP) with only the most valuable materials or those giving high yields being currently recovered in biorefineries.

Our approach integrates cell disruption with controlled and continuous separation of biochemicals using high-pressure extraction and membrane separation technologies. Reduction of necessary processing steps, resource use (e.g water and energy), and environmental impact (e.g. wastewater) are our main goals.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB