Due to the growing awareness of environmental pollution caused by plastics, the demand for environmentally friendly packaging is increasing – especially in the cosmetics and food industry. The aim of the SusPackaging project is therefore to establish a green value chain for the production of bio‑based and biodegradable packaging materials. As part of the project, Fraunhofer IGB is investigating microbial polyhydroxyalkanoates (PHA), which have similar properties to conventional plastics but are biodegradable.

SusPackaging – Sustainable production of polyhydroxyalkanoates (PHA) for packaging materials

Plastic pollution and accumulation of microplastics in the oceans are increasingly gaining public awarenes and urging the cosmetic and food industries to fulfill the demand for environmentally responsible packaging concepts. Thus, SusPackaging aims to initiate a green value chain for the production of biodegradable, bio‑based packaging materials. Polyhydroxyalkanoates (PHA) are biodegradable biopolymers that have properties similar to conventional plastics. PHAs are naturally produced by bacteria as intracellular storage granules that serve as a source of carbon and energy and may comprise up to 90 percent of the cell dry weight. Currently, high cost of production and downstream processing results in PHAs being uncompetitive compared to conventional oil‑derived polymers.

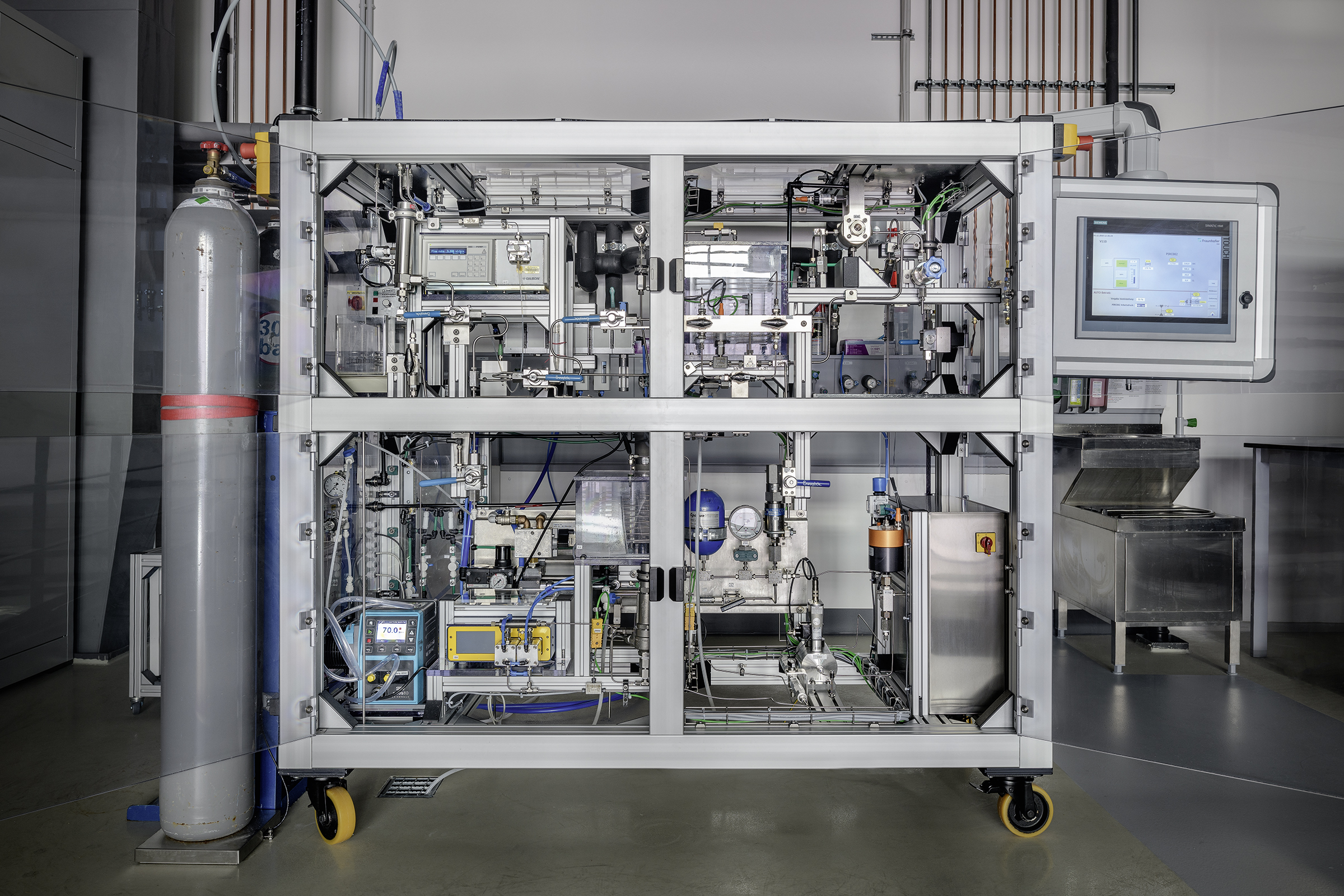

During this project, Fraunhofer IGB has evaluated the production of different PHA molecular variants through selection and isolation of microorganisms able to transform sustainable carbon sources like methane from the biogas production, sugars derived from cellulose and hemicellulose from forestry and agricultural residues, and glycerol resulting from biodiesel production. Additionally, a highly efficient, solvent‑free downstream processing approach is being developed. The use of Pressure Change Technology (PCT) and supercritical fluids for cell disruption and material recovery has been adapted for this application. Physical‑chemical properties of obtained materials, correlation to key quality requirements, and a Life Cycle Potential Analysis are being studied in cooperation with our project partners.

Project information

Project title

SusPackaging – Sustainable production of polyhydroxyalkanoates (PHA) for packaging materials

Project duration

October 2017 – September 2020

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart Coordination)

- Fraunhofer Institute for Process Engineering and Packaging IVV, Freising

- University of Stuttgart, Institute of Interfacial Process Engineering and Plasma Technology (IGVP), Stuttgart

- University of Stuttgart, Institute of Microbiology, Stuttgart

- LCS Life Cycle Simulation, Backnang

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) and the project executing organization Jülich (PtJ) for funding the project "SusPackaging", promotional reference 031B0371A.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB