Increasing operational, material, energy and ecological efficiency of biogas plants with special consideration of the production of a natural customer-specific fertilizer

Biogas plants are an important decentralized component for the expansion of renewable energies. The main need for research is to make biogas production as a whole as effective as possible and thus improve the biogas yield. The aim of the GOBi project is therefore a holistic approach: the entire process chain, from the cultivation of the plants to the yield of biogas, is to be optimized. In addition, the biomass of the plants should be used as fully as possible. Research is being conducted into how residual products can be used as fertilizers and to what extent by-products are produced that would be of interest to the chemical industry, for example. The project is being carried out by an interdisciplinary consortium of research institutes and SMEs.

Subproject Production of a natural fertilizer

One of the subprojects deals with investigations on how the fermentation residues of the biogas plant can be processed into tailor-made fertilizers. For this purpose, the fermentation residues of the biogas plant are separated into solid and liquid components. Valuable phosphorus and nitrogen salts are to be recovered from the liquid phase, which serve the plants as nutrients. The solids are dried and then processed into organic soil improvers. The energy-efficient drying process with superheated steam developed at Fraunhofer IGB is used here.

The subproject is also investigating the nutrient requirements of the plants used (maize). Fertilizer tests are carried out in the laboratory and at the test sites of the University of Hohenheim.

Subproject Natural basic chemicals for the chemical industry

Before the energy crops are fermented in the biogas plant, they are pre-treated in the silage. Bacteria ferment the complex plant material into simpler organic compounds such as lactic acid, acetic acid or butyric acid. These organic acids are also of industrial importance: lactic acid is used, for example, in the food industry as an acidifier, is an antibacterial additive in cleaning agents or – like acetic acid – in the production of bioplastics.

Another subproject at Fraunhofer IGB is therefore also investigating whether leachate with a high proportion of these acids is produced during silage and whether it pays to extract these chemicals from the leachate.

Subproject microbiome analysis to optimize biogas production

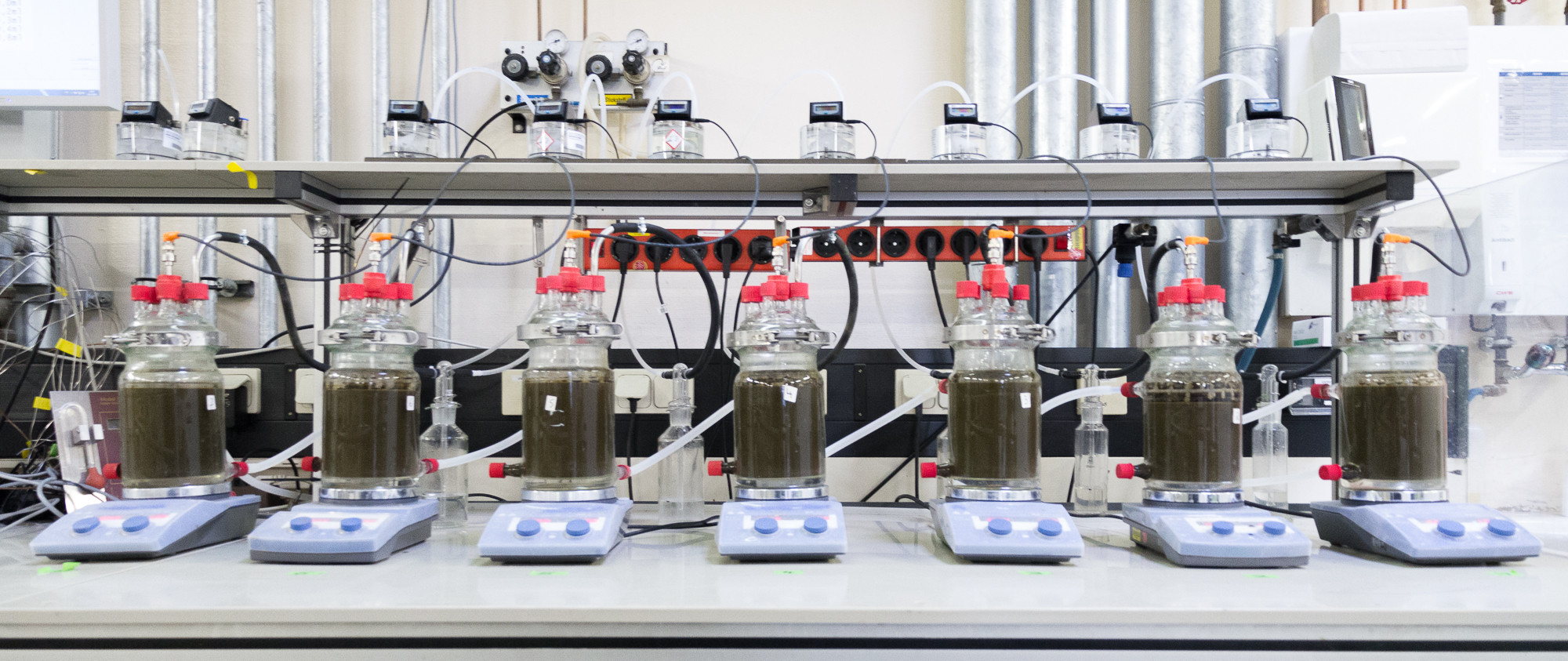

An essential factor in the efficiency of the biogas process is the composition of the microorganisms involved in fermentation. One focus of this subproject is therefore to determine the complex compositions and interactions of the microbial communities in silages and biogas fermenters. Fraunhofer IGB relies on the analysis of the metagenome and metatranscriptome. The organisms are identified by next-generation sequencing (NGS) methods directly via analysis of their DNA. On the basis of this data, the biogas processes should be further optimized and controlled by a targeted composition of the microorganism population.

Subproject Characterization of fermentation behaviour and biogas production of various silages from renewable raw materials

At the same time, the project tries to improve the core processes in gas production. The aim is to increase the yield and shorten the production time. To this end, the scientists at Fraunhofer IGB have investigated how the composition of the silage affects fermentation behaviour and biogas production and compared the productivity of a single-stage operation with a two-stage operation.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB