Economic and sustainable algae production

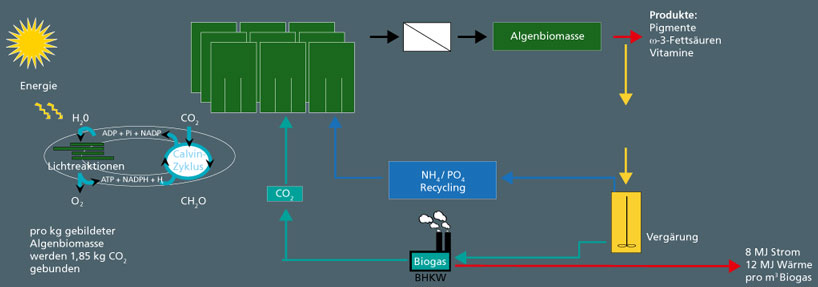

For an economic and sustainable production of algae biomass for material and energy recovery, the steps along the entire process chain must be optimized. The challenges for sustainable microalgae production in detail are:

- Energy-efficient microalgae production

This requires a photobioreactor that ensures a high rate of photosynthesis even at high cell concentrations, and whose energy requirement for algae production is lower than the energy content of the algae biomass produced. - Product extraction

Solvent and solvent quality must be matched to the products; extraction should be carried out from the wet biomass in order to avoid energy input from drying processes. - Integrating the use of residual biomass

After the extraction of the valuable materials, the lignocellulose-free residual biomass is available for anaerobic mineralisation to biogas and thus for energy value creation. - Recycling of nutrients

In addition to the use of exhaust gas CO2, the use of waste water with a high nitrogen and phosphate content contributes to cost reduction. - Water circulation system

The recirculation of water can be realized both by reusing the cultivation media and by using nitrogen and phosphate containing waste water.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB