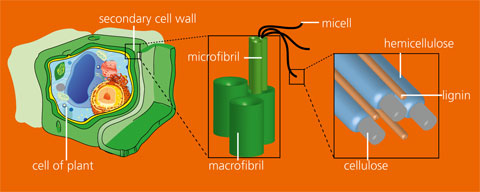

Lignocellulose, the structural material in the cell wall of all woody plants, is the most abundant renewable raw material. In 2008, the worldwide availability of raw wood was 3.4 billion cubic meters. Lignocellulose is the main component of residues such as straw or wood which, as so-called second-generation raw materials (not based on starch), do not conflict with food production.

Pulping of lignocellulose - First step towards the use of the ingredients

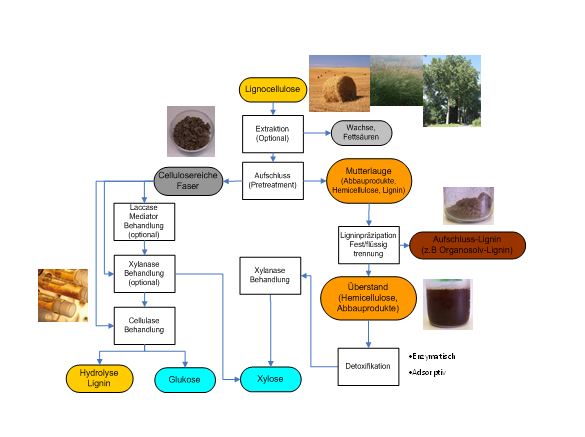

In contrast to sugar- and starch-based raw materials, lignocellulose is very stable due to its compact structure and high lignin content. Therefore, suitable pulping methods are required to effectively separate the main components lignin (aromatic polymer), cellulose (C6 sugar polymer) and hemicellulose (C5 sugar polymer). There are a variety of physical, chemical, chemical-physical and biological processes.

Organosolv pulping

The physico-chemical organosolv processes, which use organic acids and alcohols or aromatics as solvents in combination with water, are of particular interest. Especially low-molecular alcohols guarantee an energetically favourable recovery of the solvents.

The pulping of lignocellulose produces cellulose-containing fibres and a liquid digestion solution containing dissolved hemicellulose sugar and lignin. The lignin can be separated from the dissolved sugars by precipitation. The further utilization of cellulose and hemicellulose as well as lignin is also part of the competence area of the Industrial Biotechnology Group.

Various pulping methods were established and optimally adapted for different raw materials. The results obtained were used, among other things, to design a biorefinery pilot plant, which was subsequently implemented at the Fraunhofer Center for Chemical-Biotechnological Processes CBP.

During organosolv digestion, the crystallinity changes and the specific surface area of the cellulose fibres increases, which improves the enzymatic hydrolysability. However, conditions that are too harsh lead to the loss of individual fractions in the form of undesirable sugar and lignin degradation products, which can have a negative effect on the fermentability of the sugar solution. Consequently, a process was aimed at which guarantees the best possible hydrolysability of cellulose and at the same time a holistic recycling of all components. A digestion process that provides lignin and the dissolved hemicellulose in the form of technically usable building blocks for chemical derivatives makes a significant contribution to the establishment of lignocellulose biorefineries.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB