Beck A, Vogt F, Hagele L, Rupp S, Zibek S (2022) Optimization and Kinetic Modeling of a Fed-Batch Fermentation for Mannosylerythritol Lipids (MEL) Production With Moesziomyces aphidis. Frontiers in bioengineering and biotechnology 10:913362 doi:10.3389/fbioe.2022.913362

Bippus L, Briem AK, Beck A, Zibek S, Albrecht S (2024) Life cycle assessment for early-stage process optimization of microbial biosurfactant production using kinetic models-a case study on mannosylerythritol lipids (MEL). Frontiers in bioengineering and biotechnology 12:1347452 doi:10.3389/fbioe.2024.1347452

Bippus L, Briem A-K, Beck A, Zibek S, Albrecht S (2024) Ökobilanz für die Bioprozessoptimierung – Herstellung des Biotensids MEL. BIOspektrum 30(6):714-717 doi:10.1007/s12268-024-2305-8

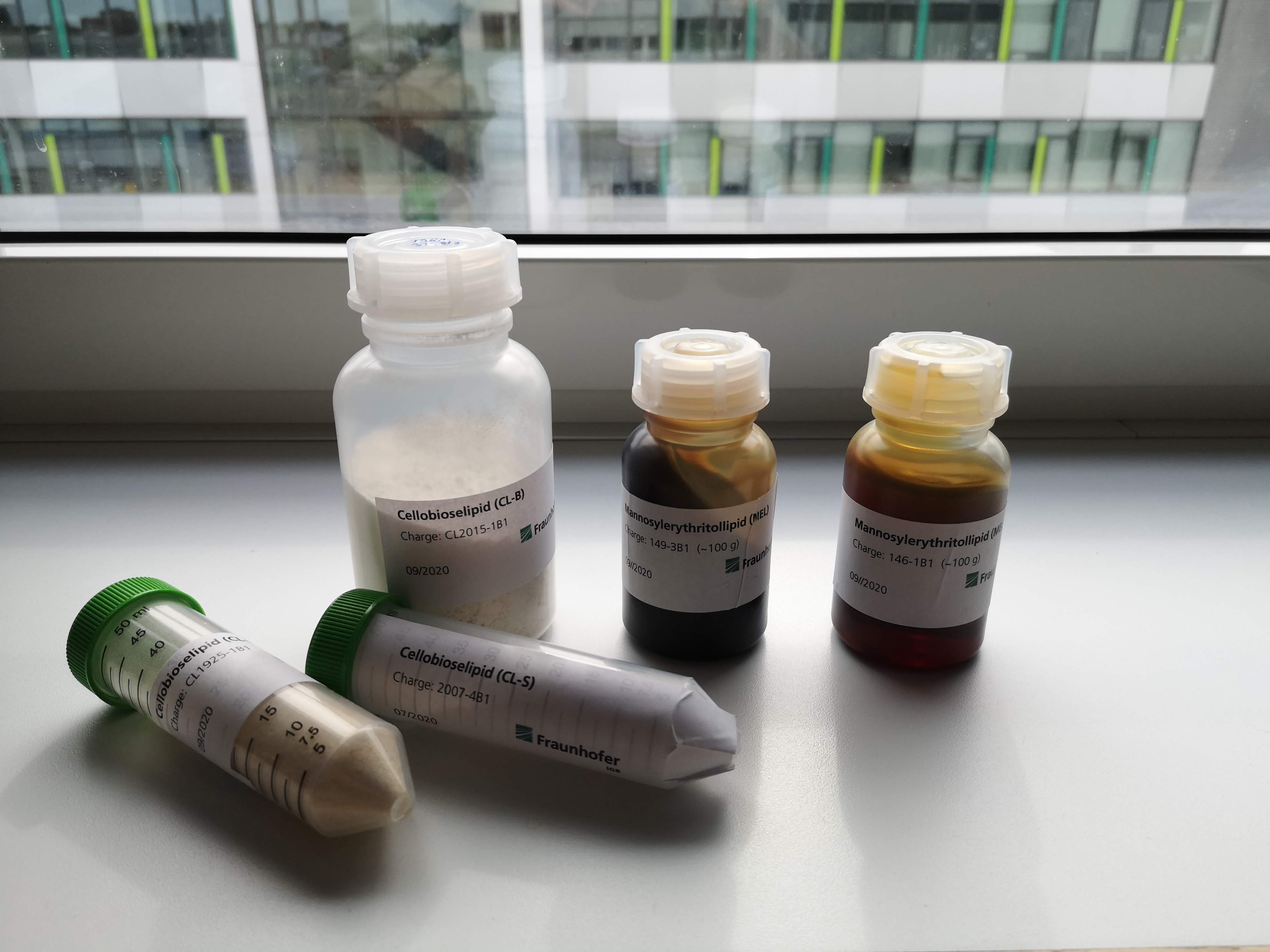

Münßinger S, Beck A, Oraby A, Zibek S (2024) Past, present and future of glycolipids from Ustilaginaceae – A review on cellobiose lipids and mannosylerythritol lipids. Journal of Surfactants and Detergents 27(5):647-689 doi:10.1002/jsde.12764

Oraby A, Briem AK, Bippus L, Rupp S, Zibek S (2024) Life cycle assessment as a driver for process optimisation of cellobiose lipids fermentation and purification. Int J Life Cycle Ass 29(9):1652-1671 doi:10.1007/s11367-024-02301-1

Oraby, A, Hug, D, Weickardt, I, Maerz, L, Nebel, S, Kurmann, J, Rupp, S, Tovar, G E M (2023). Fermentation and recovery of cellobiose lipids using foam fractionation. Discover Chemical Engineering 3(1). doi:10.1007/s43938-022-00015-0

Oraby, A, Rupp, S., Zibek, S (2022) Techno-Economic Analysis as a Driver for Optimisation of Cellobiose Lipid Fermentation and Purification. Frontiers in bioengineering and biotechnology 10:913351 doi:10.3389/fbioe.2022.913351

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB