Synthetic, bio-based or natural biomaterials are defined as materials in contact with biological systems such as cells or tissues. The minimum requirement for a biomaterial is that it must be biocompatible. Modern biomaterials, however, are even biofunctional or bioactive. For example, they transmit active signals to their biological environment by providing molecular recognition sites that serve as anchor points for coupling molecules or cells, or release biologically active molecules at the appropriate time. Also, biomaterials can imitate the mechanical and topographic properties of a natural cell environment and thus promote the growth behavior and the differentiation of cells. In this way it is possible to produce complete artificial tissues. In addition, stability and biodegradability as well as specific biological effects such as anti-thrombogenicity are crucial points in biomaterial development.

Biomaterials

Fields of research

Material development

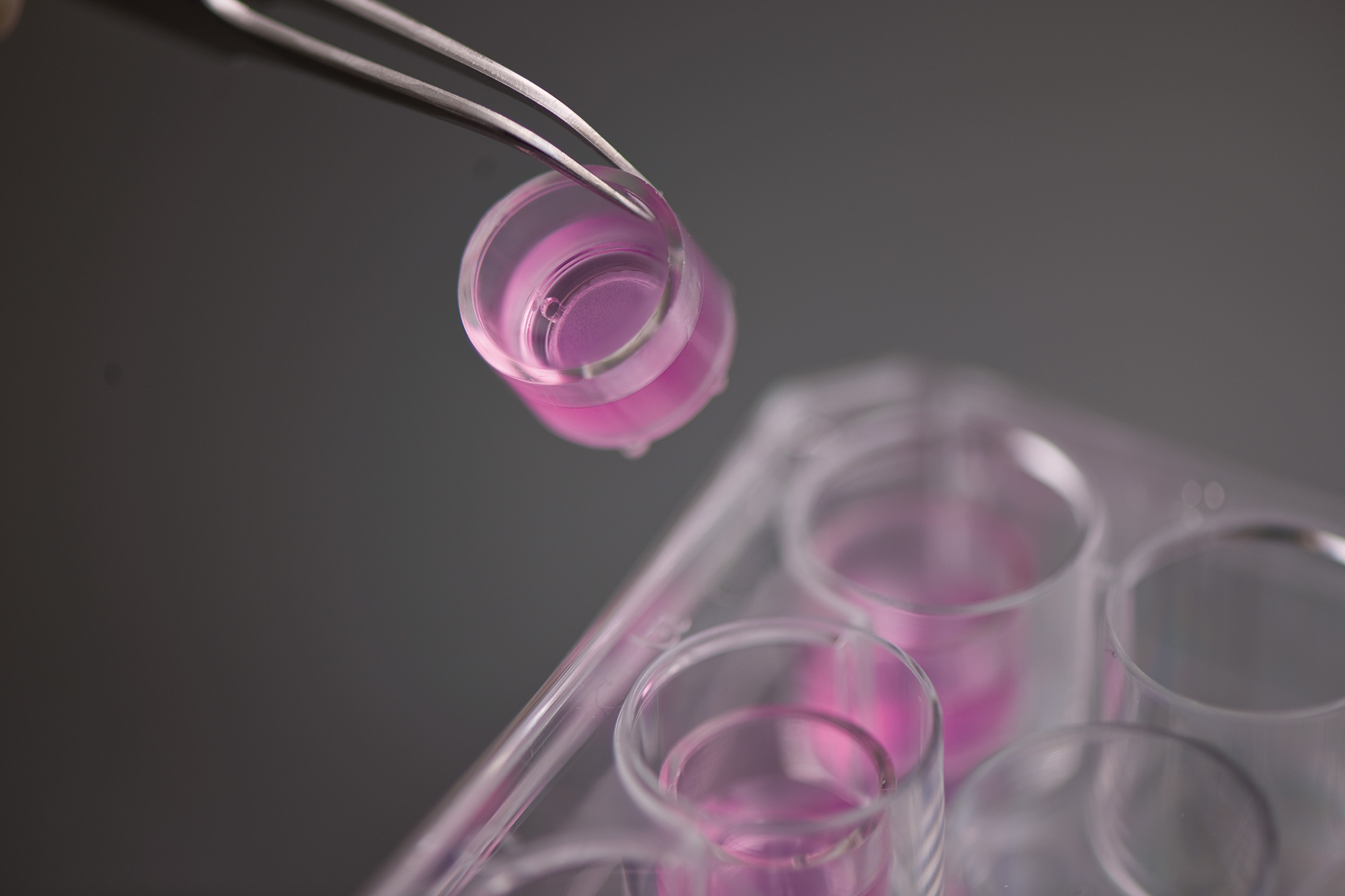

- Production of polymers and hydrogels

- Production of biofunctional particles

- Production of porous biomaterials (membranes, fibers, fleeces)

- Printable 3D matrices for the engineering of bioartificial cartilage

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB