Within the framework of the project DEUS 21 funded by the BMBF the Fraunhofer IGB is operating a semi-centralized plant for the anaerobic purification of water with integrated membrane filtration in Knittlingen. The plant generates biogas from the organic compounds contained in the wastewater and kitchen waste from approximately 170 households added via a vacuum system. The quantities of biogas achieved per day range between 8000 and 10,000 liters. As the methane content in this biogas lies between 60–70 percent, it constitutes a valuable energy source the utilization of which can reduce the demand from fossil energy carriers.

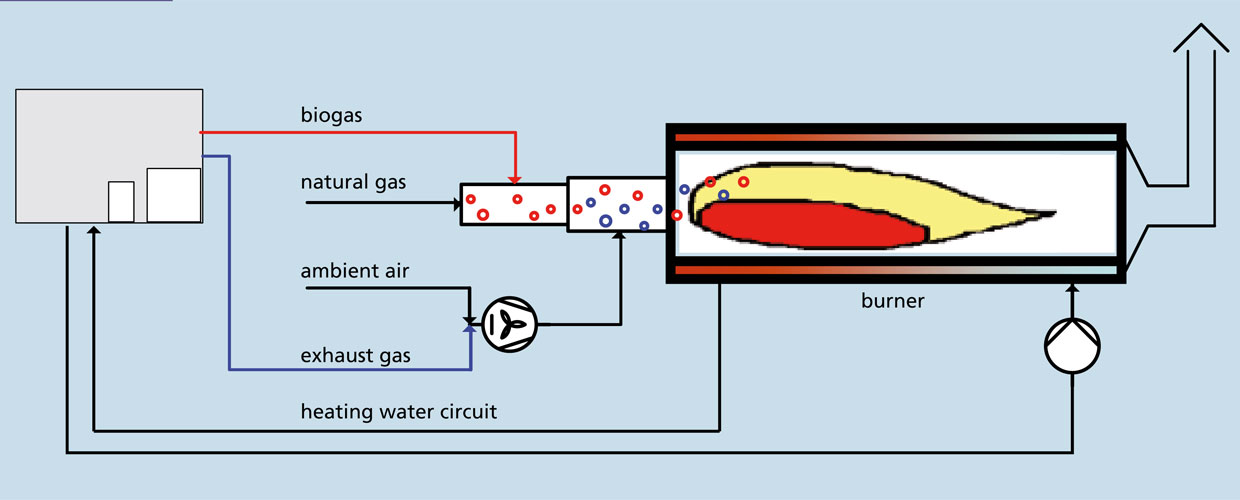

The biogas quantities generated in conventional biogas plants are considerably larger than the biogas generated at the Knittlingen plant. Plants for the utilization of relatively small amounts of biogas have therefore not been available on the market. Similarly small plants for the utilization of natural gas can not be utilized for biogas due to the different composition and the lack of accreditation. To be able to utilize the biogas with a larger aggregate, it would have to be stored in a reservoir. This is critical for explosion prevention reasons and because of its location in a residential area. In addition, for pressure storage it would be necessary to process the biogas. Therefore the Fraunhofer IGB has developed an aggregate together with C-deg GmbH in Kiel which allows for the energetic utilization of small quantities of unpurified biogas.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB