The procedure

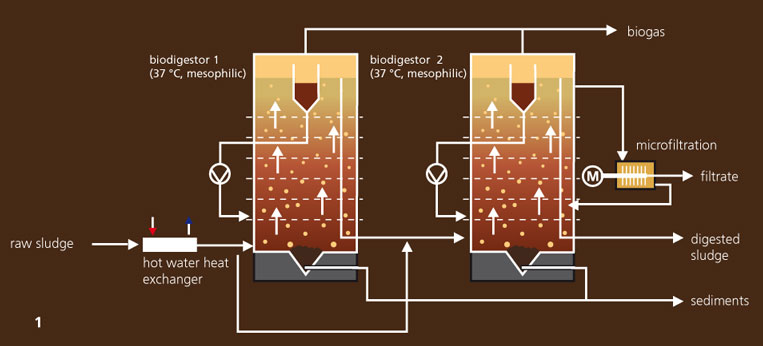

The optimization of operating conditions in sewage sludge digestion was the subject of intensive research work at Fraunhofer IGB. The result is the two-stage Schwarting-Uhde process (now Schwarting Biosystems GmbH), which was patented as early as 1979. The process, which has considerably improved efficiency, a short residence time and a high degree of degradation, is used for the anaerobic conversion of organically degradable substrates such as liquid manure, biowaste or sewage sludge. Due to the significantly increased biogas yield, it is becoming increasingly popular.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB