Challenges

Increasing costs for the purification and disposal of wastewater, regional and seasonal shortages of water, and also a growing environmental awareness on the part of companies are resulting in using these process waters, which are often required in large quantities, in closed cycles whenever possible, and removing impurities selectively or recovering valuable constituents.

In order to recirculate process waters and wastewater from industrial production processes, the impurities have to be removed – with as little effort and expense as possible.

Solutions and service offers

In order to achieve a closed cycle and permanent sustainability of process water management, Fraunhofer IGB is working on process solutions that combine biology and engineering.

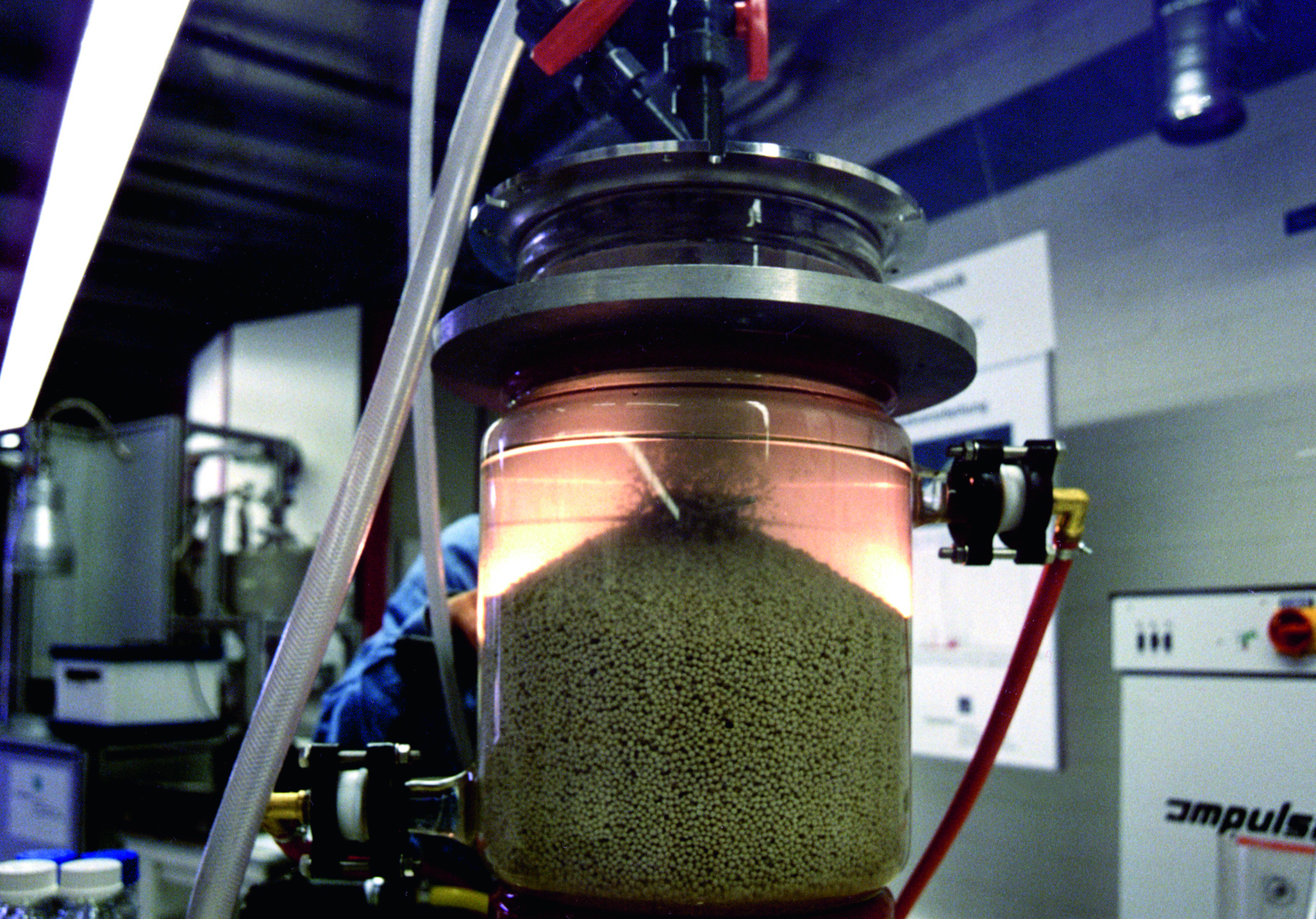

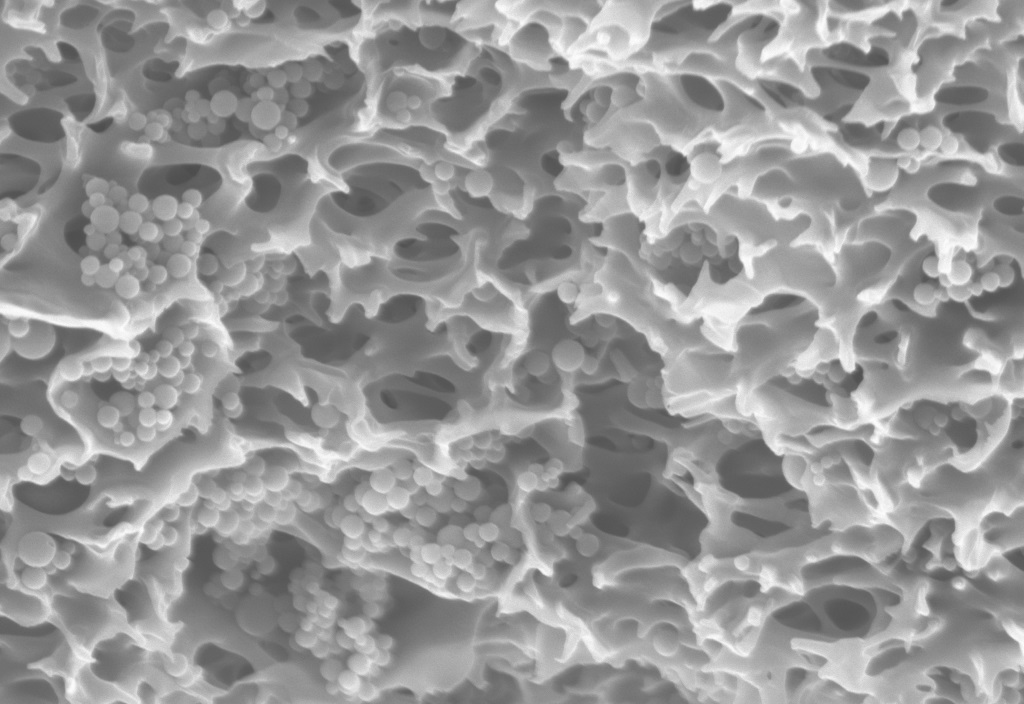

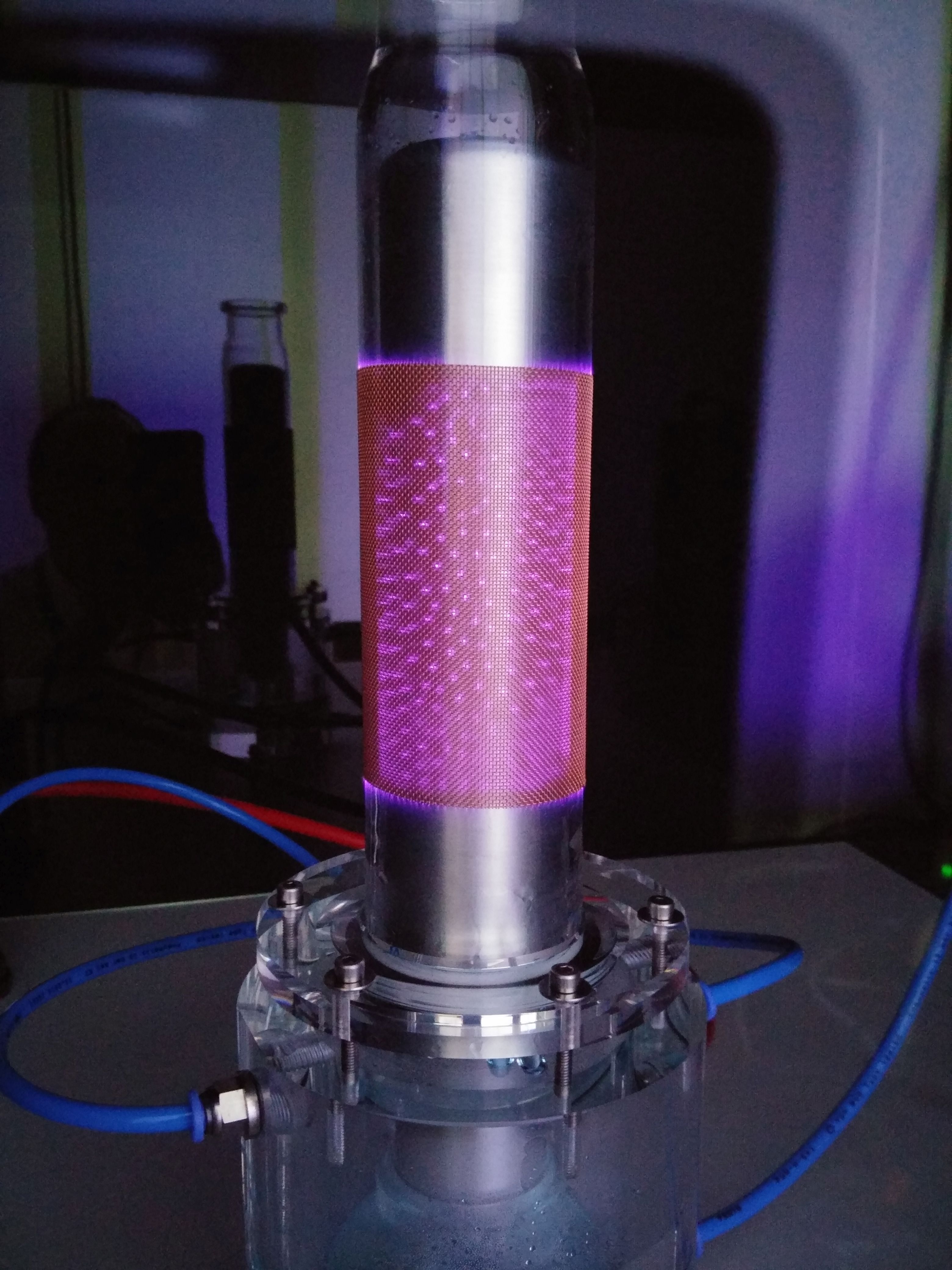

Current research at Fraunhofer IGB is therefore focused on processes such as adsorption, filtration, flocculation/precipitation, electrodialysis, oxidation and disinfection and a transition to biobased feedstocks. On the basis of many years of experience biological processes, both aerobic and anaerobic, are being further developed and optimized for an extremely wide range of applications, and combined with membrane and chemical-physical processes.

The integration into regional energy and material flow concepts in the spirit of the bioeconomy enables new solutions here. In addition to new requirements, the rapid development of the legal framework and local markets also offers great opportunities.

Scientific advice to our customers regarding their production process and its water flows is provided independently of technology and suppliers. In cooperation with industrial partners, new concepts and technologies for the sustainable treatment and purification of process water for a very wide range of applications are being developed and optimized at Fraunhofer IGB as well as scaled up to industrial scale.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB