"Green“ methanol can be produced easily from CO2 and hydrogen or syngas and renewable energy. In particular, the use of CO2 as a central raw material in chemical production has enormous sustainable potential. Especially the current political framework seeks such climate-positive approaches. Against this background, the joint research project EVOBIO, funded by the BMBF and Fraunhofer, was continued in the follow-up project EVOBIO-Demo by a Fraunhofer consortium consisting of the Fraunhofer institutes IGB, UMSICHT and IMW. Here, the focus is on the further development of a biotechnological production route for an organic acid from methanol. Here, the methanol can be obtained from synthesis gas of the TCR® process developed at Fraunhofer UMSICHT from sewage sludge. This approach thus combines the use of a waste product, namely sewage sludge, with the synthesis of a value product. Hence, this process can be embedded in a "wastewater treatment plant of the future".

Methylotrophic fermentation as a starting point

In this context, methylotrophic microbes are promising host organisms which can convert methanol to value-added products in fermentation processes. A first-generation production strain for the synthesis of an organic acid, which had already been developed in the initial EVOBIO project, was initially characterized in terms of its production performance in the follow-up project and specifically improved by metabolic engineering and bioprocess development. This newly developed process for the production of the target organic acid from CO2 is a promising future approach to support the reduction of industrial CO2 emissions.

A promising process approach

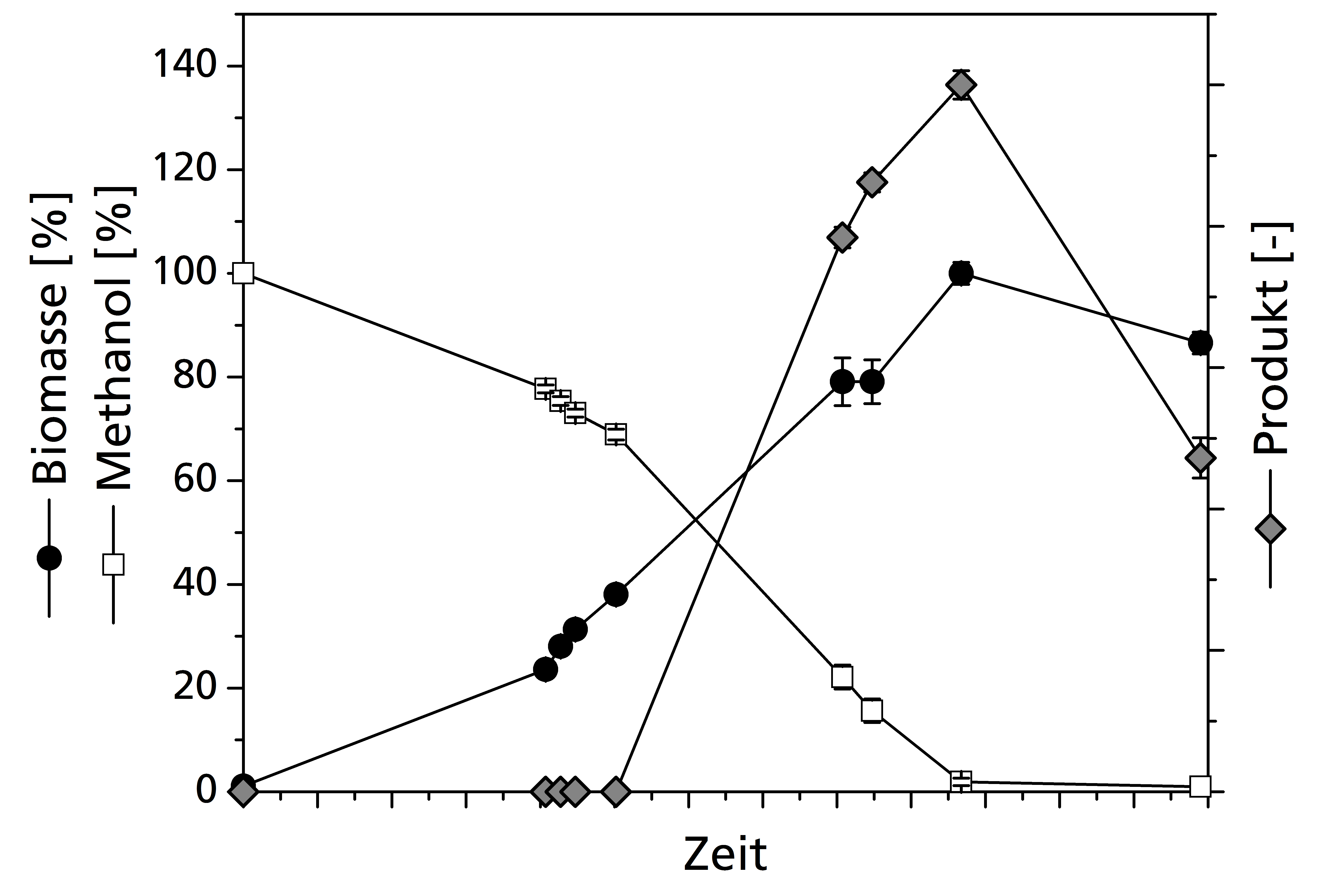

After the identification of a tailor-made production strain, the production performance was evaluated in fermentation experiments. It was demonstrated that the first generation of the production strain was capable of producing significant amounts of the target product (Fig. 1). In the following project progress, rational strain development strategies based on in-silico modelling of the metabolism were identified to further increase the production performance and the product yield. In parallel, batch- and fed-batch fermentation experiments were conducted to identify further optimization strategies for the established process. In particular, the organic acid was to be produced exemplarily from the so-called TCR® methanol provided by Fraunhofer UMSICHT in order to test the process in detail. The evaluation of the technology transfer potential to industry was carried out by Fraunhofer IMW. Finally, the results were included in an invention disclosure, which describes the developed biocatalyst.

Technology transfer to industry as a goal

These basic operations in EVOBIO-Demo demonstrated that it is possible to couple power-to-X processes with biotechnological production methods. In addition, such process cascades represent a promising approach for the valorization of CO2 or synthesis gas extracted from sewage sludge as sustainable raw materials. In the next step, the fermentation process will be further developed towards industrial application. Here, the search for interested project partners from industry has recently started.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB