Binding of functional proteins to membrane surfaces can provide them with new properties. Such biologization offers many advantages, has high industrial relevance and can be of great ecological and economical importance as a strategy for textile finishing. This applies in particular to the production of water-repellent textiles that until now have been mainly provided with environmentally unfriendly fluorinated hydrocarbons.

In the “Development of a natural fluorocarbon-free hydrophobing agent for textiles on the basis of proteins” project, we use hydrophobic proteins produced using recombinant techniques, known as hydrophobins, which are naturally produced by fungi, as well as natural cellulose anchor proteins as biological alternatives. Genes coding for the respective protein types are recombinantly assembled in modular designs such that the novel bi-functional fusion proteins can be produced in bacteria using established biotechnological methods from renewable resources. The anchor protein binds the fusion proteins to the surfaces; the hydrophobins provide the hybrid material with hydrophobic properties.

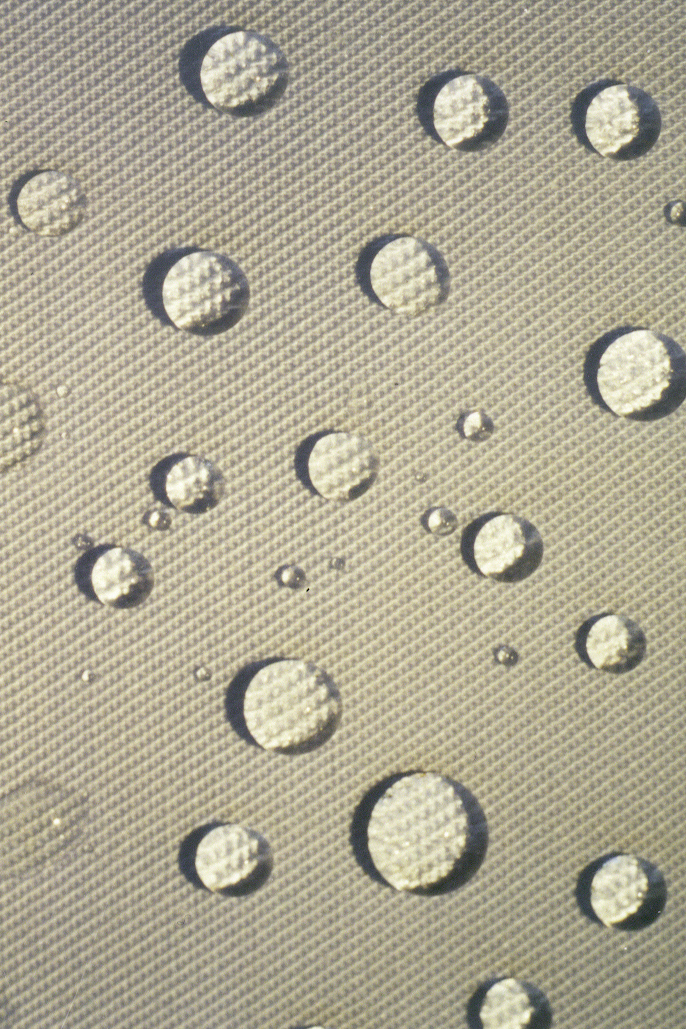

This work has resulted in an exclusive tool box of different proteins that can be applied functionally to material surfaces without any chemical or physical pre-functionalization. This leads to a changed surface energy and thus to strong hydrophobing of the surfaces. Currently, we are working to optimize purification and aqueous formulation of the fusion proteins for the application in order to make the process even more effective. Further projects with other cellulose-containing material surfaces used as substrate are planned.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB