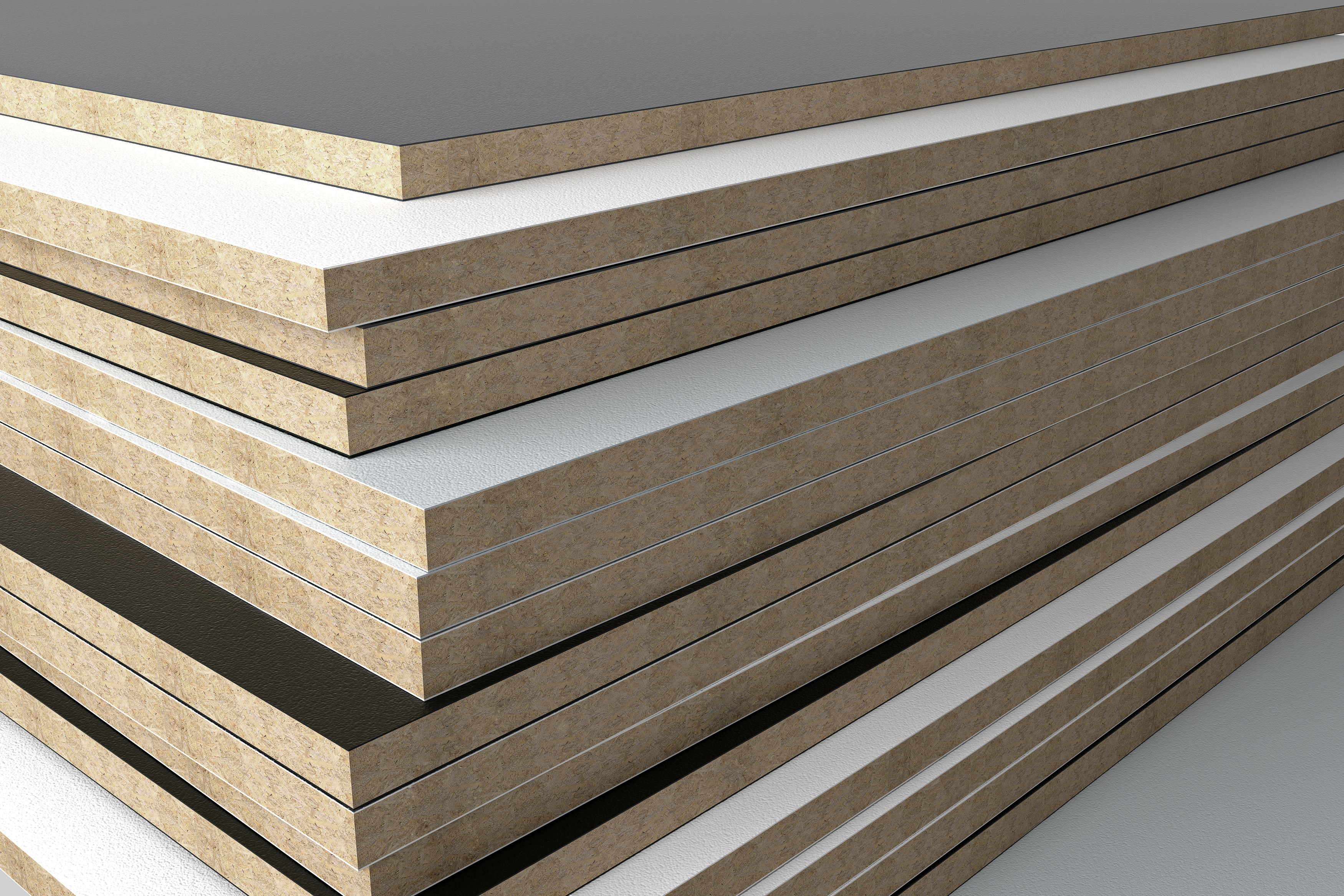

The SUSBIND Consortium develops, produces and tests biobased binders as an alternative to fossil-based binders currently used for wood-based panel board in furniture mass products. The resulting SUSBIND binder system aims to outperform current fossil-based binders containing a significantly lower carbon footprint, while also reducing formaldehyde emissions.

SUSBIND – Development and pilot production of SUStainable bio-BINDer systems for wood-based panels

Challenge

The wood board industry currently relies on the use of fossil-based binders, mainly formaldehyde-based binders. Several market factors are driving major changes in the composition and technology of these adhesive systems in the EU. Upcoming regulations foresee reduced formaldehyde emissions or ist elimination from furniture due to its effects on indoor air-quality. Manufacturers have made several attempts to produce alternative binders from renewable resources, but a biobased binder able to compete at industrial scale with incumbent chemicals does not yet exist. In order to cope with increasing global consumption and climate change, innovative products in the wood-based panel mass market are urgently needed to reduce greenhouse gas emissions and dependency on fossils.

Solution

The SUSBIND consortium develops, produces and tests bio-based binders as an alternative to formaldehyde binders currently used for wood-based panel boards in furniture mass products. The goal of the project is to substitute fossil-based chemicals with those from renewable resources. Surplus feedstock sourced from existing European biorefineries will be used for the production of binders and intermediates. SUSBIND aims at producing and validating these bio-based binders with leading wood board manufacturers for two product types: P2 particle board and medium density fibreboard.

The SUSBIND project covers the full value chain from feedstocks through to pilot production and validation by relevant research, industry and SME partners. Driven by the mass consumption needs, it includes leading furniture manufacturers and retailers.

Fraunhofer IGB deals with the chemo-enzymatic epoxidation, hydrolysis and esterification of vegetable oils and the scale-up of the process.

Impact

The resulting SUSBIND binder system aims to outperform current fossil-based binders containing a significantly lower carbon footprint, while also reducing formaldehyde emissions. A sustainable and economically viable binder will increase the marketability of bio-based furniture products. The SUSBIND results will not only benefit public health and help mitigate climate change but also strengthen the European furniture industry by providing a cost-efficient bio-based alternative to formaldehyde-based binders and a competitive green advantage over cheaper, imported products.

Project information

Project title

SUSBIND – Development and pilot production of SUStainable bio-BINDer systems for wood-based panels

Project duration

May 2018 – April 2022

Project partners

- RTDS Group (Coordination)

Research partners

- CE Delft, Netherlands

- Centro de Investigaciones Biológicas (CIB), CSIC Instituto de Recursos Naturales y Agrobiología de Sevilla (IRNAS-CSIC), Sevilla, Spain

- Fraunhofer IGB, Stuttgart, Germany

- Kompetenzzentrum WoodK+, Austria

- TU Dresden, Germany

Industry partners

- Cargill, Germany

- EGGER, Austria

- JenaBios, Germany

- IKEA, Sweden

- Valbopan, Portugal

Funding

The project "SUSBIND" has received funding from the Bio Based Industries Joint Undertaking (JU) under grant agreement n° 792063. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio Based Industries Consortium.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB