So far, agricultural and forestry residues such as hay, straw, wood and plant residues have been used insufficiently. In the VALORKON project, a fermentation-free biorefinery concept is being developed based on the drying and torrefaction process with superheated steam established at IGB. A new process chain is used to selectively separate valuable substances such as acetic acid, furfurals and phenols, which are released in the volatile phase during torrefaction.

VALORKON – Valorization of condensate streams from the torrefaction of biomass

Recovering platform chemicals from condensate streams from the torrefaction of biomass using superheated steam

Initial situation

With over 100,000 GWh or 370 PJ (Basic data Bioenergy Germany 2017, Fachverband Nachwachsende Rohstoffe e.V.) in Germany hay, straw, wood and plant residues represent an energy and material potential that has so far been insufficiently exploited. However, in the case of direct combustion or torrefaction according to the state of the art, valuable organic ingredients such as acids (acetic acid, levulinic acid, formic acid), furfurals or aromatic compounds (phenol, vanillin) are not fully utilized in the sense of a biorefinery; the economic efficiency of energy utilization thus remains limited.

Project goal and approach

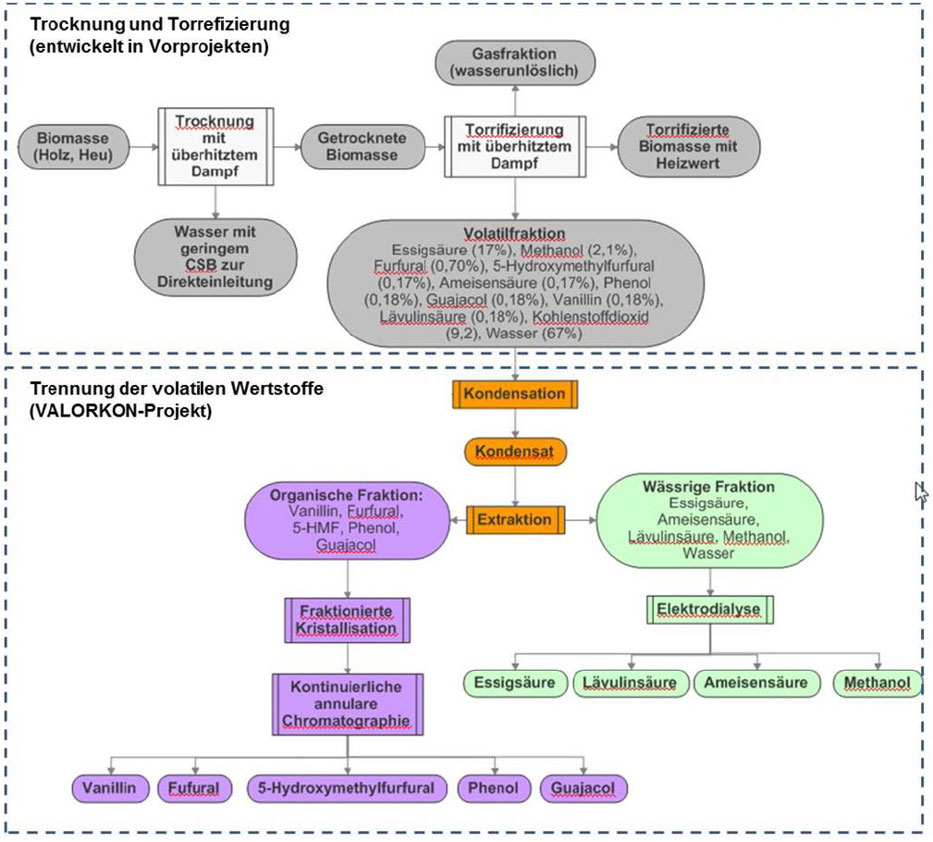

With VALORKON, a completely new – fermentation-free – biorefinery concept for biomass from agricultural and forestry residues is being developed. A process for drying and torrefaction with superheated steam (SHS) is used, which Fraunhofer IGB has developed together with its project partner Heckmann in previous projects. The drying and torrefaction process with superheated steam (SHS) is an excellent way of producing highly efficient biomass with good storage stability from lignocellulosic residues. This end product has a wide variety of applications: high-quality fuel, adsorbents, soil conditioners and even input material for pyrolysis or gasification processes.

The innovation in VALORKON is to obtain high-value basic chemicals of high quality (purity > 95 percent) in addition to conditioning the residues to a hydrophobic material. Fraunhofer IGB and Heckmann are therefore developing a process chain with which these valuable substances can be selectively separated from the volatile phase released during torrefaction.

Project results

Value creation from the valorization of condensable volatile substances

A by-product of SHS torrefaction is a condensate made up of water and potentially valuable substances, such as organic acids, methanol or furfural. In the “VALORKON” project funded by the BMBF, Fraunhofer IGB worked to develop separation processes that could be used to recover such platform chemicals at high purity levels from the condensate produced by the torrefaction of beech wood chips.

Separation of condensate streams

Fraunhofer IGB set up a batch rectification unit to separate the condensate streams into individual fractions. In combination with other separation processes such as extraction and electrodialysis, the researchers were able to recover furfural from the condensate at a very high purity level (95 percent). The purification of other valuable substance fractions, for example organic acids, is part of the ongoing work.

Environmental and economic assessment

In parallel to the technical work carried out at Fraunhofer IGB, Reutlingen University conducted an environmental and economic assessment of the entire process – from drying and torrefaction through to resource recovery using the condensate. The result is encouraging so far: The current process has a positive CO2 balance and promising economic potential.

Outlook: Entire biorefinery process

The next steps towards pre-industrial development are the recovery of other products from the condensate, the transfer to a continuous, scalable complete process and its application using other biomass residues.

In addition, there are plans for a joint publication with Reutlingen University on the environmental and economic potential of the entire biorefinery concept.

Publications

Roy, B.; Kleine-Möllhoff, P.; Dalibard, A. Superheated Steam Torrefaction of Biomass Residues with Valorisation of Platform Chemicals—Part 1: Ecological Assessment. Sustainability 2022, 14, 1212. https://doi.org/10.3390/su14031212

Roy, B.; Kleine-Möllhoff, P.; Dalibard, A. Superheated Steam Torrefaction of Biomass Residues with Valorisation of Platform Chemicals Part—2: Economic Assessment and Commercialisation Opportunities. Sustainability 2022, 14, 2338. https://doi.org/10.3390/su14042338

Project information

Project title

VALORKON – Valorization of condensate streams from the torrefaction of biomass

Project duration

March 2019 – February 2022

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart

- Heckmann Metall-und Maschinenbau GmbH, Verden

- Reutlingen University, Reutlingen

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) for funding the project "VALORKON", promotional reference 031B0664A, in the "Technologieinitiative Bioraffinerien" program.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB