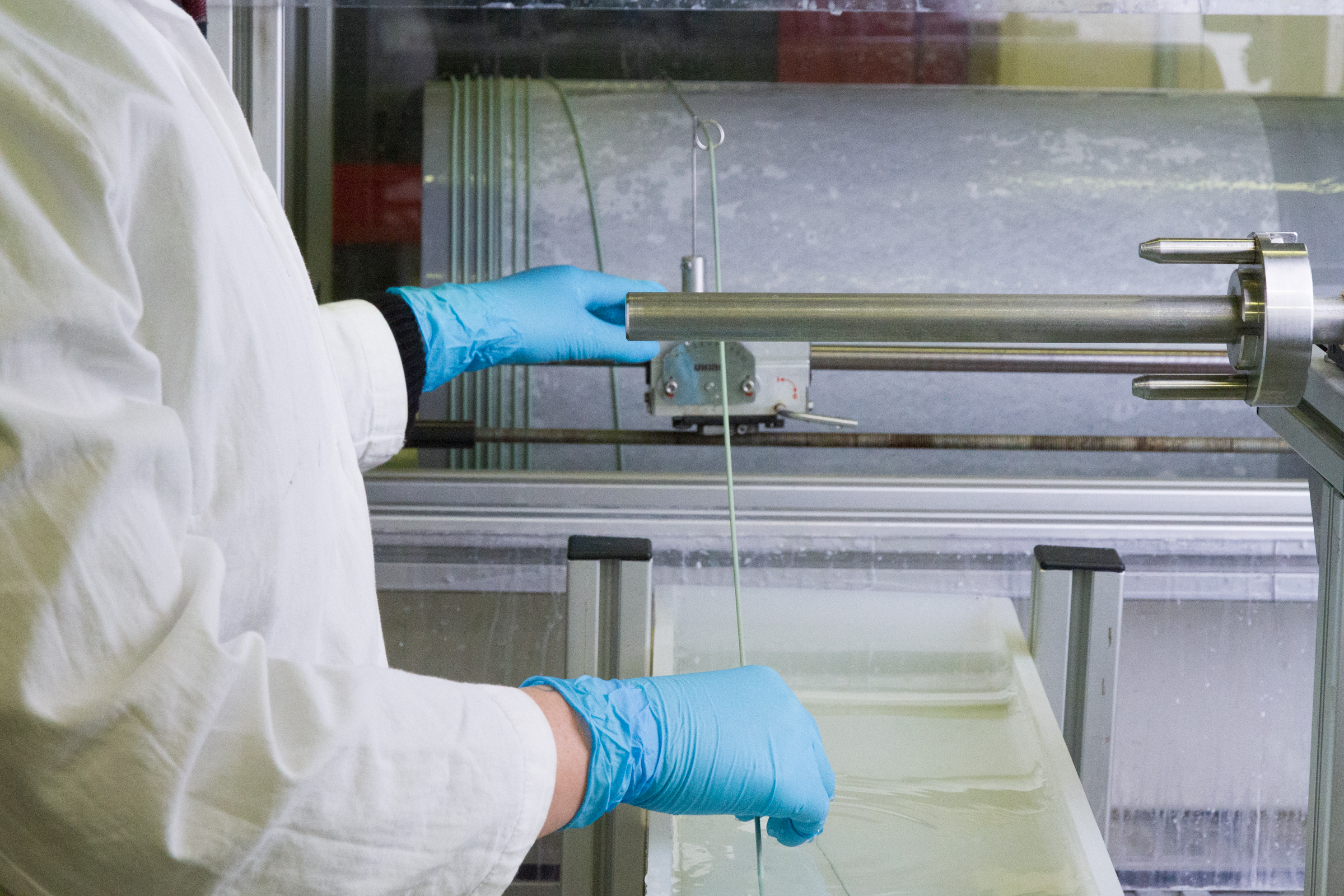

Proprietary wet-spinning process for asymmetric capillary membranes

For the production of asymmetric ceramic capillary membranes, we have established a wet-spinning process that can be used to produce capillaries with outer diameters of between 0.5 and 4 millimeters and wall thicknesses of 50 to 500 µm. In a first step, we produce microfiltration membranes, which can then be modified by coating them with selective layers.

Processing of various ceramics and metals from laboratory to pilot scale

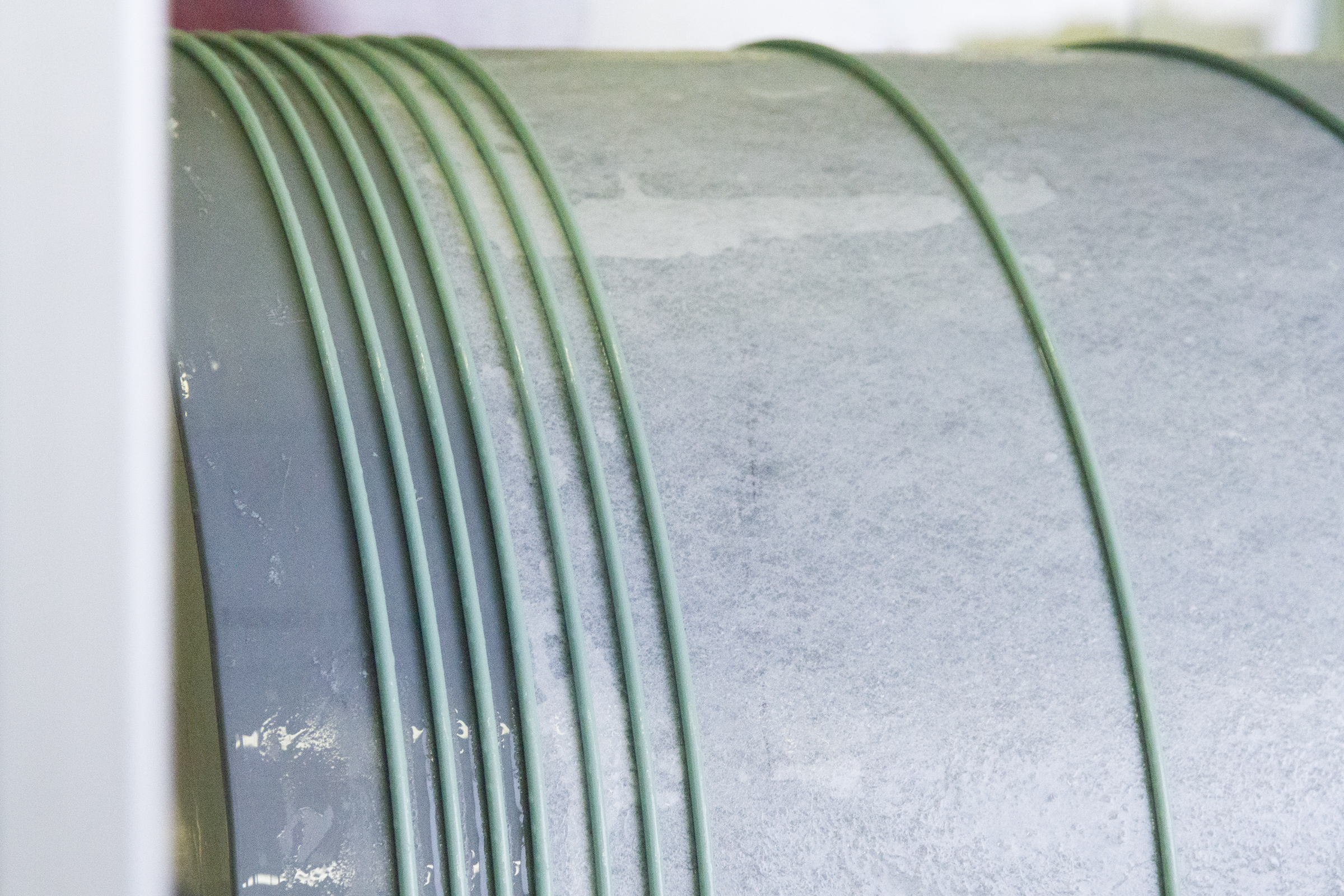

In addition to oxide ceramics, other ceramics (e.g. SiC) and even metals (e.g. stainless steel) can be processed. Production capacities range from just a few meters on a laboratory scale to production in pilot scale.

Sintering processes for the production of dense capillary membranes from perovskite

When functional ceramics such as perovskite are used, we can manufacture dense capillary membranes by sintering processes. The geometry of the capillaries can be influenced by different spinning nozzles as well as by spinning parameters.

By such mixed ionic and electronically conducting materials we can achieve high oxygen permeation. Due to the lattice transport of oxygen in the dense material, the selectivity from O2 to N2 approaches infinity. Therefore, dense perovskite capillaries are of interest as membranes for synthesis gas production (gas partial oxidation) and for the production of pure O2.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB