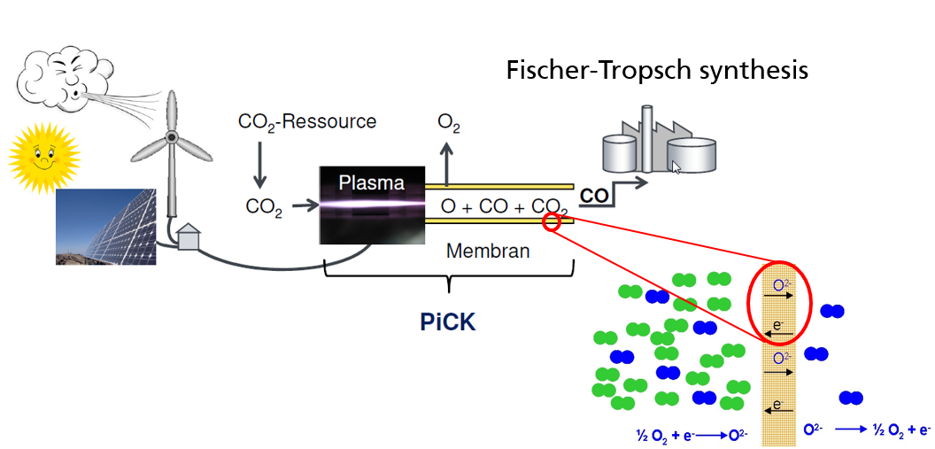

The Kopernikus satellite project PiCK is developing a novel process employing implementing regenerative electrical energy to utilize climate-damaging CO2 as a carbon source. A combination of plasma and membrane processes will be used to break down CO2 into O2 and CO, which serves as the starting product for the synthesis of platform chemicals and chemical energy stores such as methanol. Within the framework of the project, gas-tight ceramic capillaries were produced at IGB for the first time. These capillaries are both CO2-stable and suitable for the separation of oxygen from a plasma.

PiCK – Plasma-induced CO2 conversion

The development aims to make CO2 usable as a chemical feedstock and for chemical energy storage, thereby contributing to the targeted climate goals. A cost-efficient and resource-saving combination of plasma and membrane processes will be used to split CO2 into O2 and CO, which can serve as a feedstock for the synthesis of platform chemicals such as methanol (Fig. 1). The membrane process is needed to prevent the recombination of CO and O2 into CO2.

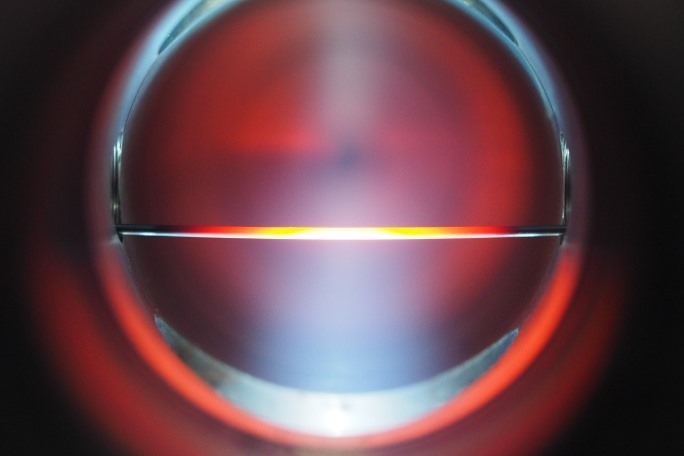

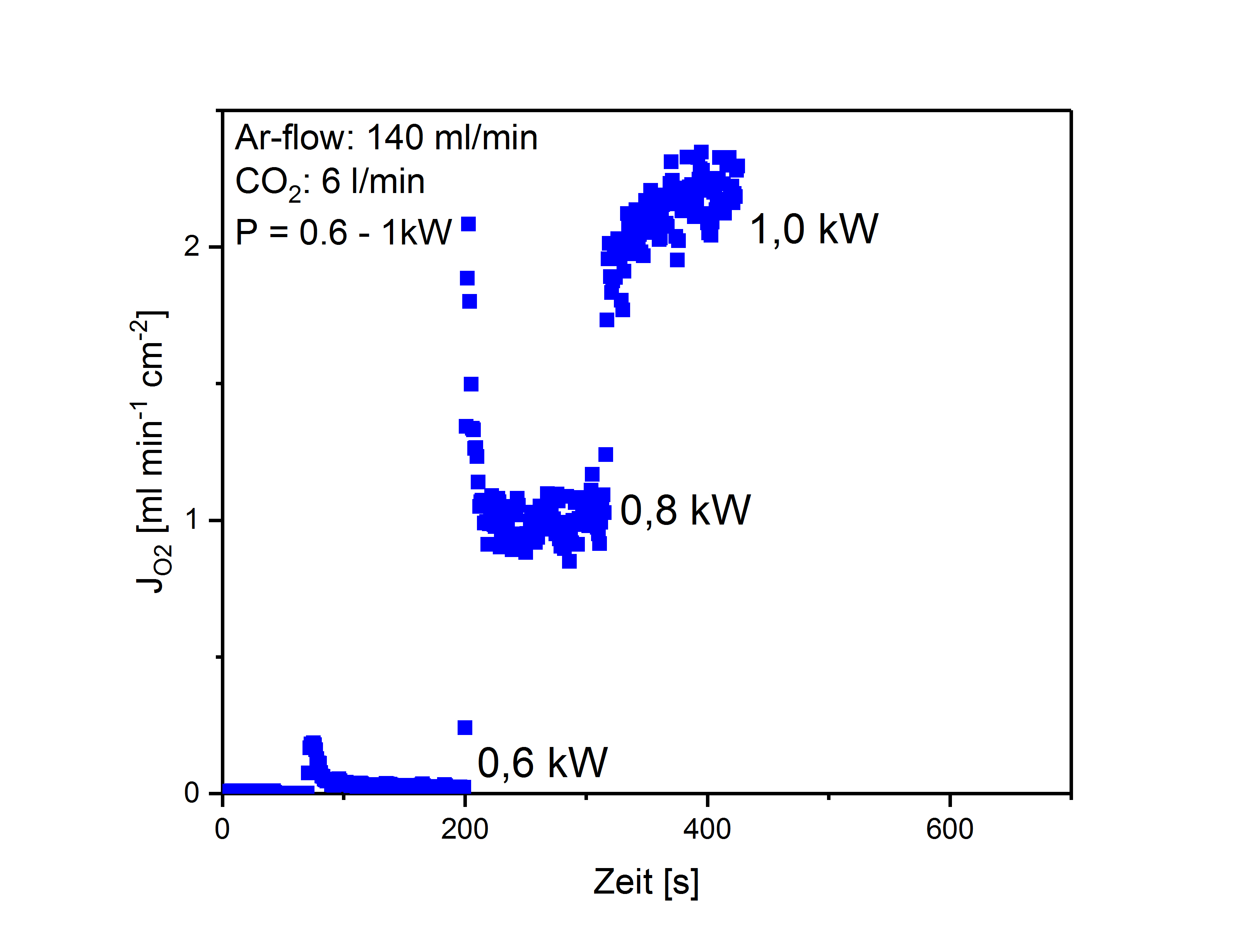

The focus of the work at the IGB was on the development of a suitable membrane that can efficiently separate oxygen on the one hand and be used in plasma on the other. For this purpose, a mixed conducting ceramic material (LawCaxCoyFezO3-δ; LCCF) was selected for the fabrication of the membranes, which has already been described as CO2-tolerant in the literature. Using an established wet-spinning process followed by sintering, it was possible for the first time to reproducibly fabricate gas-tight LCCF capillaries (Fig. 2) that are both CO2 stable (>200 h) and suitable for oxygen separation (O2 permeance of 1.0 ml min-1 cm-2 at 900 °C).

These show very good thermal stability and good oxygen permeance in a plasma (2.3 ml min-1 cm-2 at 1 kW; see Fig. 3 and 4). Such capillaries have not yet been described in the literature.

Project information

Project title

PiCK – Plasma-induced CO2 conversion

Project duration

February 2017 – February 2020

Project partners

- University of Stuttgart, Institute of Interfacial Process Engineering and Plasma Technology IGVP, Dr.-Ing. Andreas Schulz (Coordination)

- MUEGGE GmbH, Reichelsheim

- University of Stuttgart, Institute for Materials Science

Funding

We would like to thank the German Federal Ministry of Education and Research (BMBF) and the project sponsor Jülich (PTJ) for funding the project "PiCK", promotional reference n° 03FSK2S3D.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB