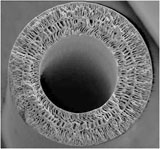

Commercially available ceramic membranes

Ceramic materials generally exhibit very good chemical, thermal and mechanical stability. For this reason, ceramic membranes are widely used for the filtration of liquids in the food, chemical and pharmaceutical industries and in bioprocess engineering. Ceramic membranes are available in various geometries, e.g. as plates, rotating discs, tubes or multichannel elements. However, these commercially available membranes are relatively heavy and their production is costly. The space density of the elements is in many cases far below 1000 m2/m3. The ceramic capillaries produced at Fraunhofer IGB are characterized by the fact that they combine the advantages of ceramic membranes with high packing densities and are both compact and lightweight.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB