Chemicals which are released into the aquatic environment in very low concentrations as micro-pollutants or “emerging contaminants”, are increasingly attracting attention. Their number, frequency of occurrence and concentration are increasing continuously. Pharmaceuticals and drug residues as well as endocrine disruptors (pseudo-estrogens) are considered especially critical, since they have been reported to cause pharmaceutical or hormonal effects in surface waters. They can be accumulated over the food chain and have been detected in groundwater and even in drinking water. They are chemically diverse and, due to their chemical structure and extremely low concentration, are not eliminated in municipal wastewater treatment plants based on current technology and processes.

Elimination of micro-pollutants from hospital wastewater

Experimental plant at the source

For the best results, technical solutions for the elimination of micro-pollutants must be applied at the sources of discharge of substances into municipal wastewater. In a project supported by the Willy Hager and Robert Bosch foundations, the Fraunhofer IGB investigated the biological treatment of wastewater from a ward at the Robert Bosch Hospital in Stuttgart. The experimental plant is based on a membrane-bioreactor technology developed at Fraunhofer IGB (Figure 1) involving a rotating disk filter for cell retention. In the first experimental phase, the bioreactor was run anaerobically and its performance was monitored by the determination of biogas production and other operating parameters like COD, pH, dry matter, total nitrogen, ammonium and volatile fatty acids. Analyses of the micro-pollutants were carried out by the Institute for Urban Water Supply and Sanitation, Water Quality and Waste Management (ISWA) of the University of Stuttgart.

Results

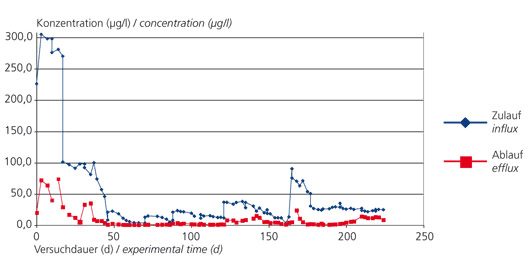

Over an experimental period of a year, about 200 different micro-pollutants were detected in extremely fluctuating concentrations. Over 50 of these substances were pharmaceuticals or their metabolites. Also detected were cleaning agents and flavors, as well as polymer plasticizers. Cleaning agents, flavors and plasticizers were degraded efficiently, as were easily degradable pharmaceutical active substances, such as caffeine

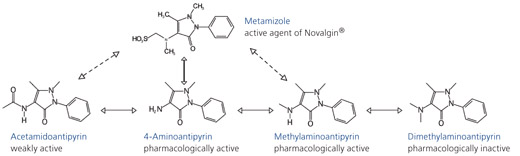

(Figure 2), which constitutes an active pharmaceutical ingredient in many drugs. In many cases, caffeine is not eliminated in municipal wastewater treatment plants and is present in surface waters, where it acts as an insecticide. Some pharmaceuticals like the psychotropic drug clomethiazole and the analgetic metamizole were converted into pharmaceutically inactive metabolites (Figure 3). Other active components such as carbamazapine, an anti-epileptic drug, known to be recalcitrant compounds, were not degraded significantly.

Outlook

The experiment showed that various micro-pollutants that are commonly released in the discharges of municipal wastewater treatment plants can be degraded or converted to inactive metabolites by specific treatment of hospital wastewater. However, some of the most recalcitrant pharmaceuticals, which are by now more or less ubiquitously present in the aquatic environment, could not be degraded. There is need of further research to develop adequate technologies for the complete elimination of these substances. In a follow-up project, a second, aerobic bioreactor will be added at the experimental plant, in order to test the degradation of pharmaceuticals in a two-stage anaerobic / aerobic process. Another project will focus on developing specific adsorbents for non-degradable pharmaceuticals, based on the NanoMIP technology developed at Fraunhofer IGB.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB