These devices create a closed feedback loop in which vital parameters are recorded and provide the input for therapeutic intervention. Pacemakers, for example, are capable of responding to the need for increased blood flow to the muscles, for instance during physical exercise, by adjusting the stimulation pulse rate. Theranostic implants record numerous different biosignals, which they process, analyze and transmit to an external receiver. These signals then provide the basis for therapeutic intervention, which can take the form of electrical, biochemical or mechanical stimulation.

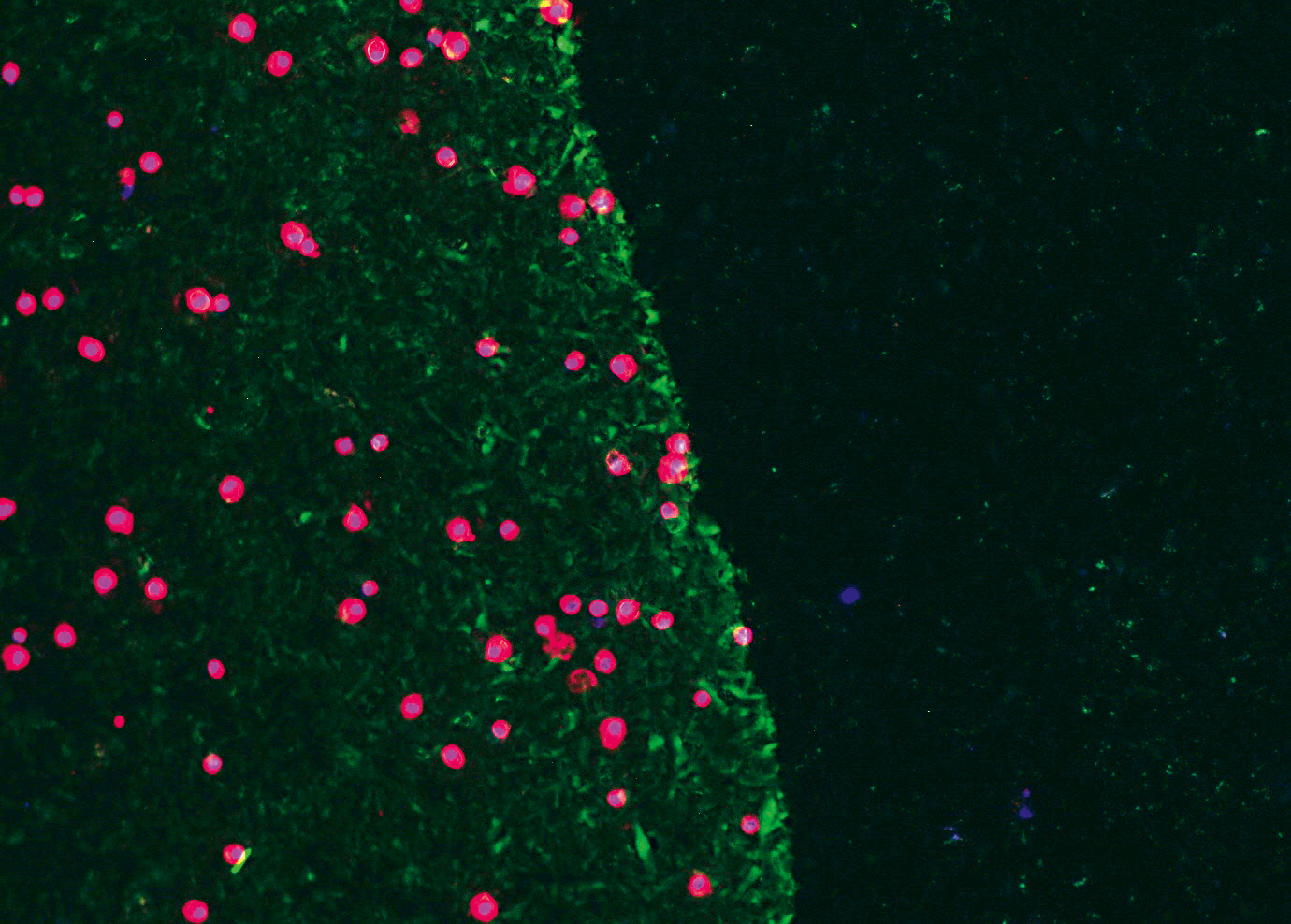

Theranostic implants must be able to function reliably in vivo for many years, preferably throughout the patient’s life, despite being exposed to constantly fluctuating cell growth in the damp and warm environment of the human body. This is one of the greatest challenges facing the engineers developing these highly complex sensor-actuator systems, which also need to be as small and light as possible. A high degree of biocompatibility with the surrounding tissue is therefore a fundamental requirement, because the implants might otherwise cause a rejection response.

The partners in this project will develop three demonstration models. Their choice of applications was based on diseases that account for a high proportion of the costs borne by German health insurers. The top items on this list are cardiovascular diseases, skeletal system diseases and neuromuscular diseases.

In each of these cases, medical implants are being used more and more frequently to heal the disease or attenuate its symptoms, and to improve the patient’s quality of life.

Smart hip-joint prostheses – skeletal system demonstrator

The hip prosthesis being developed by Fraunhofer researchers as part of this lead project is equipped with electronic sensors and actuators that enable the physician to monitor the fit of the artificial hip joint and the bone ingrowth without further surgical intervention, and to readjust the position of the implant if necessary.

Sensor implant for monitoring blood circulation – cardiovascular demonstrator

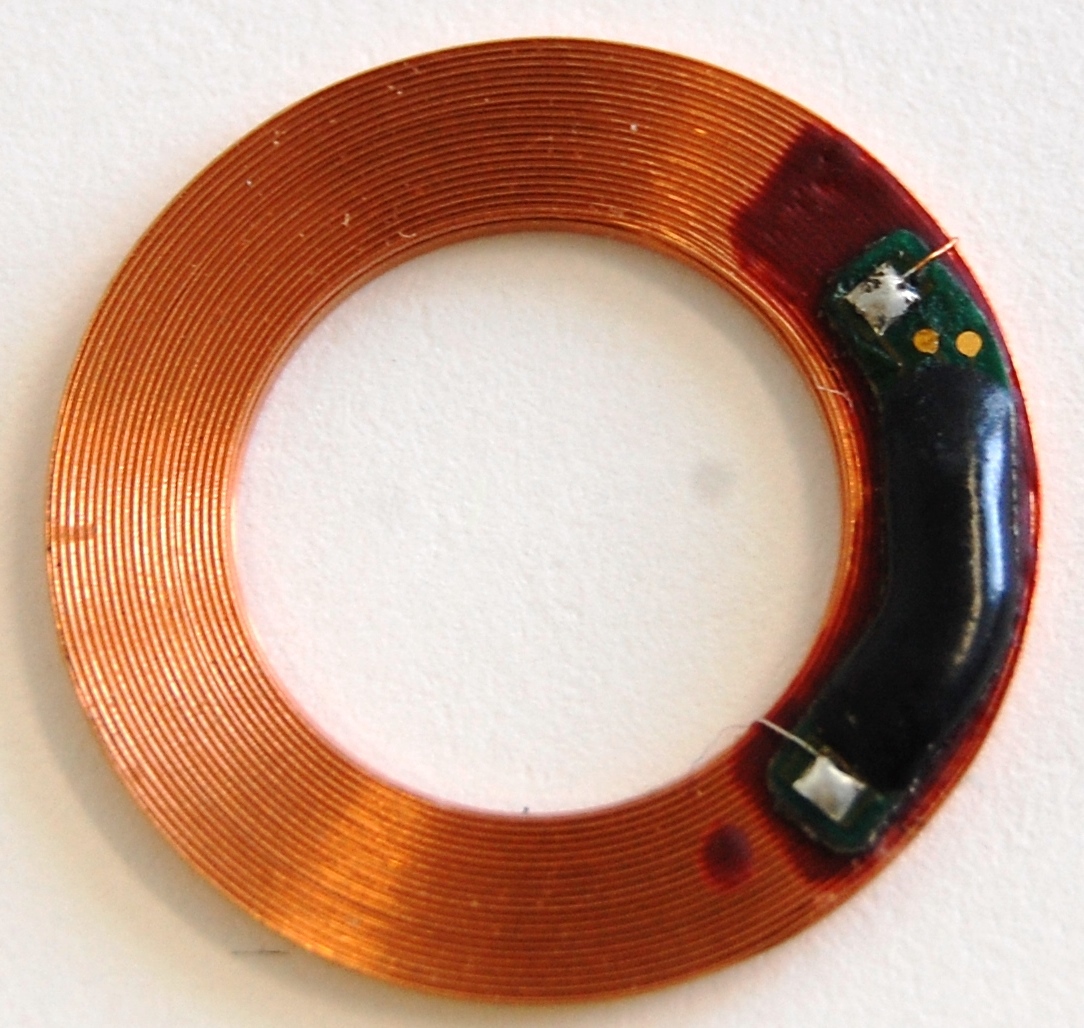

The challenge that the researchers have set themselves is to develop smart sensors based on microsystems technology and to encapsulate them in such a way that they can be durably implanted in the patient’s body. Apart from measuring blood pressure, they can also be used to measure other parameters such as acceleration and temperature, and transfer the data to an external receiver. The data obtained in this way will facilitate early diagnosis and improve the disease prognosis by enabling optimized drug treatment. Other advantages include less time in hospital and reduced treatment costs.

Myoelectric prosthetic hand controller – neuromuscular demonstrator

raunhofer researchers are developing a myoelectric prosthetic hand controller capable of providing sensory feedback. The movement of each finger of the artificial hand is controlled on the basis of muscular contractions and the associated changes in bioelectric potential. This allows for complex movements. An array of electrodes, which records the myoelectric signals generated by muscular contractions, provides a direct interface between the technical and biological systems. The control of complex prosthetic systems requires a coordinated response involving the greatest possible number of independently generated myoelectric signals. In amputation patients, these signals originate either from the still-intact arm muscles or from the chest muscles after targeted muscle re-innervation (TMR).

Outlook

The objective is to create a set of technological tools for creating a platform that will provide a basis for developing and manufacturing implantable medical devices and systems quickly and according to a modular approach. In order to carry out this project, the participating Fraunhofer Institutes have pooled their expertise in many different specialist areas in order to create an all-round solution to the need for theranostic implants. This approach guarantees results at the cutting edge of technological and scientific progress.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB