At Fraunhofer IGB we produce customer-specific nano- and microparticles with cores of organic material from commercially available polymers or tailor-made polymer materials using different polymerization techniques such as miniemulsion or dispersion polymerization.

Polymerization processes

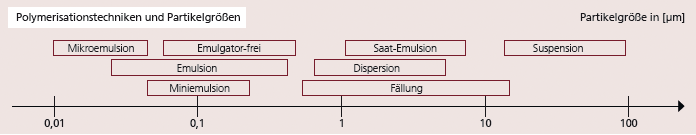

Method and particle size

Achievable particle sizes range from a few nanometers to several 100 micrometers. An overview of the available methods is given in the scheme.

Mini emulsion polymerization

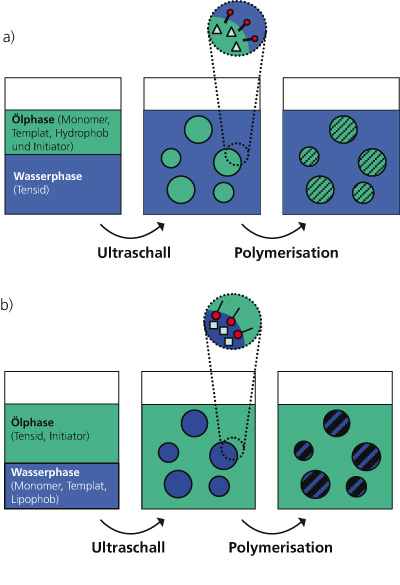

At Fraunhofer IGB, molecularly imprinted polymer nanoparticles are represented by miniemulsion polymerization with typical particle sizes in the range of 50 to 300 nm. This process is a heterophase polymerization in which two immiscible liquid phases are homogeneously and stably emulsified under the influence of high shear forces, the use of surfactants and co-stabilizers. The resulting nanodroplets of monomer, template molecule and osmotic reagent form nanoreactors in which the polymerization takes place. The resulting polymer nanoparticles are direct images of the emulsion droplets in terms of size and morphology.

This technique of synthesizing molecularly imprinted polymer nanoparticles, which has been patented by Fraunhofer IGB, offers the advantage over other common methods of polymer nanoparticle synthesis such as emulsion polymerization or precipitation polymerization that the synthesis - although complex - is carried out in a single step with quantitative yield and independent of the diffusion of the educts.

In addition to classical miniemulsion polymerization, which is used for the molecular imprinting of hydrophobic molecules, the process can be carried out in an inverse miniemulsion polymerization. This technique can be used to produce nanoparticles for the molecular recognition of hydrophilic molecules such as peptides and proteins.

Emulsion polymerization

Nanoparticles with active ester surface: "surfmers"

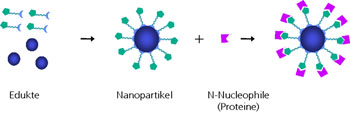

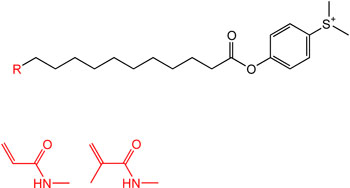

At Fraunhofer IGB we provide a class of molecules with modularly structured active ester surfmers (surfactant monomer), which provide three completely different reactivities in a single molecule and can thus be used for the simple synthesis of nanoparticles with binding sites for e.g. proteins:

- The function of a nanoparticle stabilizing emulsifier.

- The function of polymerizability by radical chain reaction.

- An active ester group that is stable against polymerization or storage, but can be used under easy-to-realize conditions for covalent anchoring of further components such as biomolecules.

The first half of "surfmer" is derived from surfactant, which means surface-active agent or surfactant. The second half of the word is derived from monomer. We have developed a two-step reaction pathway for the synthesis of active ester surfmers from simple building blocks.

Surfmer technology for producing nanoparticles in a single step

Our surfmer-based technology enables the single-stage production of nanoparticles with tailor-made anchor sites for biomolecules. This enables the replacement of costly production processes with several different process steps that have been used in everyday technical applications up to now.

Surfmer technology also enables particles to be produced that are many times smaller than the beads currently used for immobilizing biomolecules. Typical particle diameters range from 80 to 200 nanometers. The nanoparticles carry a defined number of anchor points for further chemical reactions of the particles, for example for the immobilization of biomolecules or the covalent crosslinking of nanocomposites.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB