Organic acids are used in numerous industrial sectors as well as in the cosmetics industry and medical technology. In a subproject of the joint project EVOBIO, we have enabled the methylotrophic bacterium Methylorubrum extorquens AM1 to selectively produce simple difunctional organic acids from methanol using metabolic engineering. This allows the value-added use of green methanol from CO2 or synthesis gas.

Biotechnological production of organic acids from methanol

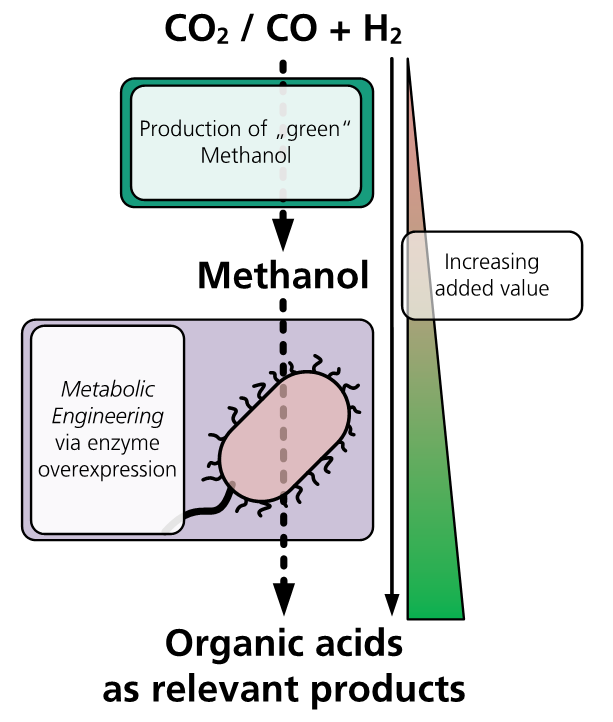

Added value by biotechnical conversion of "green" methanol

“Green" methanol produced from carbon dioxide (CO2) or synthesis gas (a mixture of carbon monoxide, CO for short, and hydrogen) offers high potential as a key raw material for the sustainable chemical industry of the future. Against this background, IGB scientists worked on the development of a biotechnological production route for organic acids from methanol as part of the Fraunhofer joint project EVOBIO.

Metabolic engineering of Methylorubrum extorquens

Methylotrophic microorganisms are a promising platform for the efficient utilization of methanol for value creation in microbial fermentation processes. The focus of the subproject conducted at Fraunhofer IGB was on the bacterium Methylorubrum extorquens AM1, which was harnessed to produce simple organic acids from methanol using methods of metabolic engineering.

The targeted acids are of great economic interest as polymer building blocks. Their conventional production is usually based on chemical processes and requires harsh process conditions as well as toxic solvents and reagents. Here, fermentative processes can offer resource-saving and an ecologically sustainable alternative. However, it should be noted that fermentations traditionally depend mostly on sugars as a substrate. From the viewpoint of sustainability, the scalability of production is limited in this case due to competition for use within food production. The use of CO2-based methanol as a fermentation substrate avoids such competition and opens up the possibility of establishing sustainable and scalable production routes to valuable organic acids. At the same time, methylotrophic fermentation results in new utilization options for CO2 as a carbonaceous feedstock for tomorrow's chemical industry.

Organic acids as target products of the EVOBIO subproject are widely used in numerous industrial sectors as well as in the cosmetics industry and medical technology. In addition, difunctional organic acids are used as monomer building blocks in the production of polymers and thus offer a broad and highly relevant range of applications for methylotrophic fermentations.

Optimization of production strains

To establish the fermentation platform, work in the EVOBIO subproject initially focused on engineering a suitable bacterial production strain. Initial production strains were identified by introducing heterologously expressed enzymes into M. extorquens. Building on these first generation strains, the production of organic acids from methanol was investigated. Testing of 13 enzymes from seven donor organisms in enzyme assays showed that ten of the introduced enzymes had relevant activity in vivo in comparison to the negative control. The resulting strain variants were finally evaluated in fermentation experiments with methanol as the sole carbon source and potential overproduction of the target products was evaluated. In follow-up projects, the developed production strains will now be specifically optimized to obtain efficient biocatalysts that are suitable for use in an industrial environment and meet the needs and specifications for future commercial production.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB