New extraction and fermentation processes offer access to a wide range of products for the food and feed industry from resources that have been insufficiently tapped to date. These include, for example, alternative proteins from plants, insects or microalgae, but also (modified) carbohydrates. Further functional ingredients can also be obtained from microorganisms and microalgae or via new fractionation technologies from byproducts from the agricultural and food industries. Due to their antioxidant, immunostimulant or antimicrobial properties, they are suitable for use in animal feed or as food supplements. For this purpose, we develop cultivation methods and product-friendly separation processes, for example for extraction and purification.

Ingredients for food, animal feed and cosmetics

Extraction and fermentation processes

Product-friendly processes for extraction and fractionation

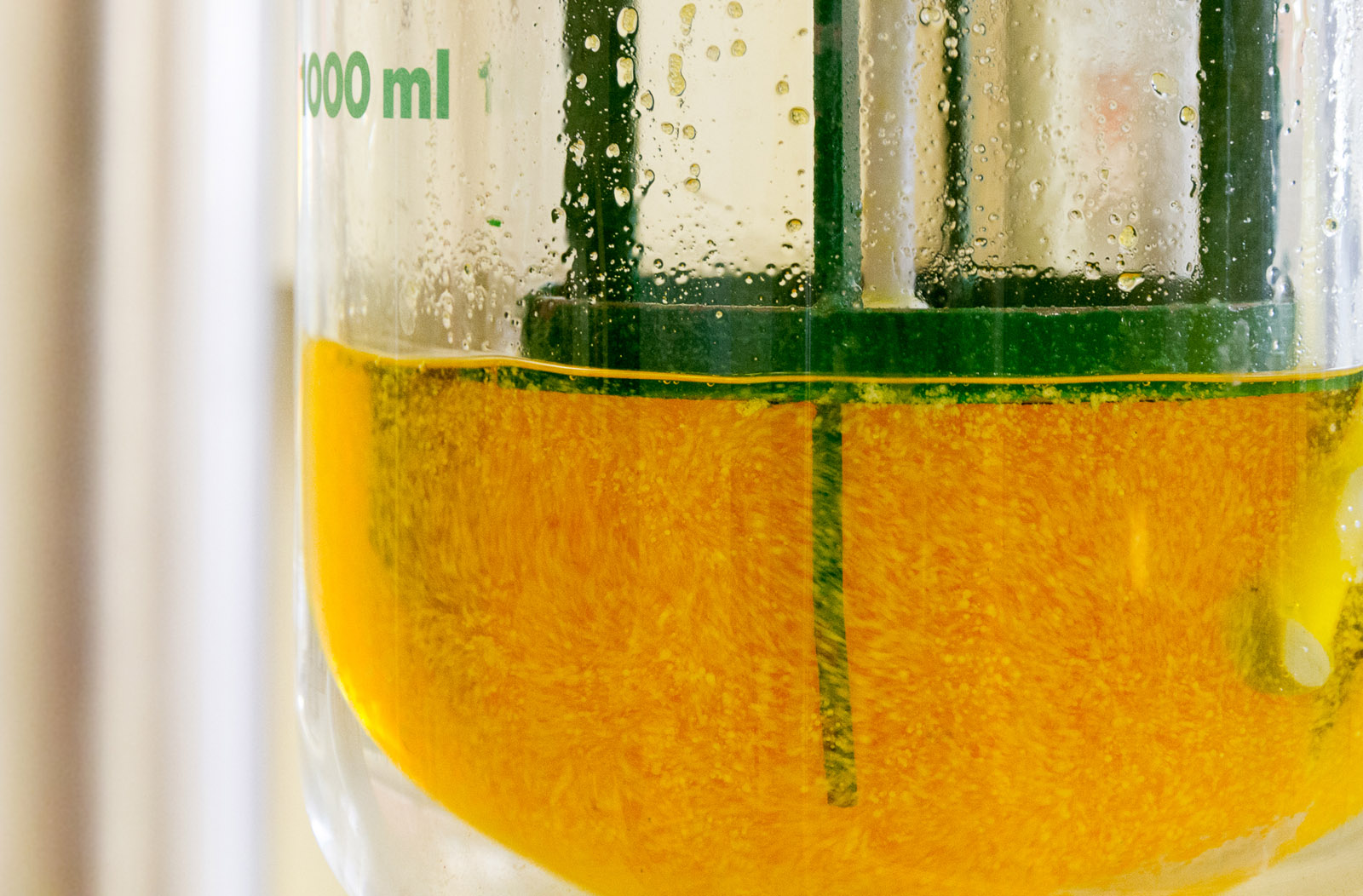

For the efficient extraction of functional ingredients from biogenic raw or residual materials and intermediate products in agricultural and food production, we at the IGB are developing robust extraction processes that are gentle on the product.

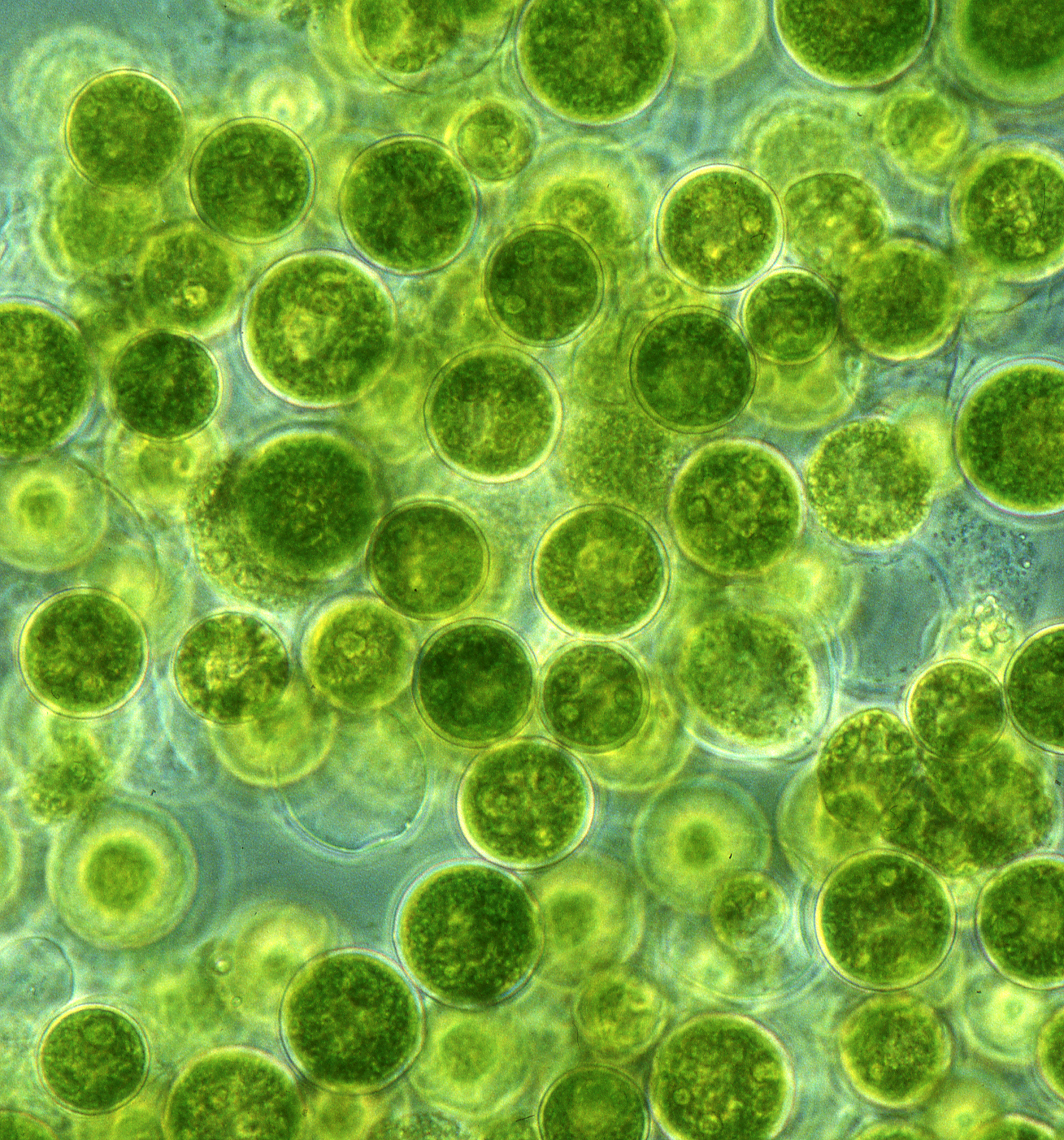

For cell disruption and thus the release of intracellular ingredients from microalgae, for example, we use high-pressure technology in combination with pressure change technology (PCT).

Various separation processes are used for the subsequent fractionation and purification of the ingredients.

Fermentation processes

The Industrial Biotechnology Group at Fraunhofer IGB develops and optimizes processes for the biotechnological production of, for example, organic acids or alcohols, proteins and food substitutes, other ingredients for food, food supplements and animal feed.

With the Bioprocess Scaling Group at Fraunhofer CBP in Leuna, we can support start-ups as well as small and medium-sized companies from Germany, Europe and beyond – by providing equipment and know-how for scaling up and optimizing fermentation processes and the associated downstream processes.

Ingredients

Functional ingredients from algae

Microalgae form a variety of substances with antioxidant or anti-inflammatory properties. For the production of valuable substances from microalgae – such as omega-3 fatty acids (EPA) and the carotenoids fucoxanthin, lutein or astaxanthin – we develop efficient extraction processes using supercritical fluids and high-pressure liquid extraction (PLE). The aim is to preserve the technofunctional and nutritional properties of the products for applications in the food and cosmetics industries.

Organic acids, biosurfactants and enzymes

Organic acids have a preservative effect, biosurfactants can be used as emulsifiers and enzymes have become important aids in the food industry, for example when it comes to the saccharification of starch or the accelerated ripening of meat. Fraunhofer IGB establishes and optimizes biotechnological processes for the conversion of biogenic raw and residual materials up to pilot plant scale.

- Bioprocess Engineering

- Scaling of biotechnological processes at Fraunhofer CBP (cbp.fraunhofer.de)

Proteins

Need for "alternative" proteins

Proteins are essential for human and animal nutrition. Climate change and environmental pollution pose new challenges for protein production. Protein sources from plants, algae, insects and fungi offer an alternative to animal-based foods. In the FutureProteins lighthouse project, Fraunhofer is therefore pursuing the goal of developing pioneering technologies for agriculture and the food industry.

Fermentative production of proteins

Proteins of non-animal origin are becoming increasingly important due to growing consumer demand for vegan foods. Milk proteins and other proteins of high nutritional value can also be produced by fermentation, for example. Please contact us if you are interested!

High-quality rapeseed proteins for nutrition

The mild process conditions of the EthaNa process, for which a pilot plant was built at Fraunhofer CBP (see below: Oilseed biorefinery), produce a rapeseed concentrate rich in high-quality, non-denatured proteins during the extraction of rapeseed.

The EthaNa rapeseed concentrate is free from hulls and secondary plant substances and contains only very small amounts of undesirable tannins and bitter substances. The high protein content of currently 42-43 percent corresponds approximately to that of cold-pressed, partially dehulled rapeseed cake from decentralized oil mills. The non-denatured proteins are easily soluble in water and can therefore be extracted and used as an alternative vegetable protein source in meat substitute products, for example. The EU project Like-a-Pro is researching how rapeseed concentrate can be used as a source of protein for the production of foodstuffs.

Rapeseed concentrate can also be used as a high-quality animal feed: it is low in glucosinolates and contains only a small amount of fiber.

- Fraunhofer Lighthouse Project "FutureProteins"

- Bioprocess scaling at Fraunhofer CBP (cbp.fraunhofer.de)

- EthaNa – Piloting the ethanolic native extraction of de-hulled rapeseed (cbp.fraunhofer.de)

- Like-A-Pro – From niche to mainstream – Alternative proteins for everybody and everywhere (cbp.fraunhofer.de)

Oilseed biorefinery at Fraunhofer CBP

Here, the mild EthaNa process is used to process oilseeds, which is operated at ambient pressure and a maximum of 70°C in order to avoid denaturation of the proteins and other quality-reducing reactions. It enables holistic utilization of the raw materials – including proteins – and higher-quality product fractions compared to conventional processing of oilseeds.

- Oilseed biorefinery (cbp.fraunhofer.de)

Preservation processes: drying and sterilization

Longer shelf life with the same product quality – food, cosmetics and active ingredients need to be stabilized or preserved without affecting the taste or damaging functional ingredients.

With our superheated steam drying process, we can dry food and animal feed in an energy-efficient way and thus preserve them for longer.

UV irradiation with newly developed excimer lamps enables us to inactivate bacterial contamination on surfaces such as eggshells.

Packaging – Functional surfaces for durability and safety

Barrier layers, e.g. against water vapor or oxygen, are playing an increasingly important role, especially in the food industry, as they protect the product against unwanted oxidation or drying out.

We are also developing surfaces from which liquid/viscous products can run off better.

Another application of the plasma technology established at Fraunhofer IGB is security labels, which guarantee the originality of the packaging and thus protect against product piracy.

Analysis, testing, evaluation

Fraunhofer IGB develops three-dimensional in-vitro models based on human cells and tissue, cell-based assays and rapid tests that can be used to analyze ingredients and active substances for various parameters.

To detect pyrogenic substances (remains of bacteria, fungi or viruses), we use the receptors of the innate immune system in our cell-based test system. A new rapid test stick can be further developed for the detection of allergens in food.

Utilization of residual materials and recovery of recyclable materials

In order to establish sustainable value-added cycles as well as the most economical production processes possible, we also develop processes to separate valuable by-products or residual materials from food production for the further use of functional ingredients (pigments, antioxidants, proteins and peptides) or to convert them into valuable materials, e.g. using catalytic or biotechnological processes.

We have also already established various processes for recovering nutrients (phosphorus, nitrogen, potassium) from wastewater or waste fractions.

Finally, organic freight can be fermented into biogas to create added value.

We would be happy to advise you on which methods are suitable for your production processes!

- /content/igb/en/research/_alt_food-processing-technology/recovery-of-valuable-products-from-food-industry-by-products-and-wastes.html

- Upstream processing of renewable raw materials and biogenic residues

- Nutrients from food and animal feed industry

- Efficient processes for biogas production from of organic waste and renewable raw materials

- Wastewater as a resource: Utilization and recovery of wastewater ingredients

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB