We also develop biopolymers for use as packaging for foodstuffs or for medicinal products (see Health business area). By using advanced coatings or the special functionality of biobased monomers, we are able to create new properties for materials. Examples here include the transparent Caramid-polyamides that Fraunhofer IGB has developed from terpenes.

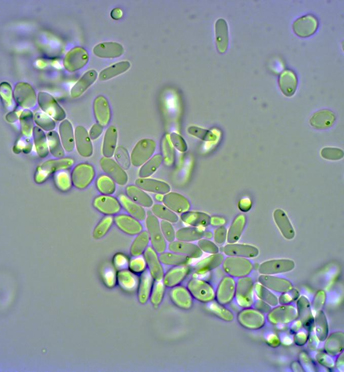

Based on renewable raw materials such as sugar, plant or animal based lipids or chitin, we have also been able to demonstrate methods of synthesizing monomers for the production of polymers, e.g. from short- and long-chain dicarboxylic acids and fatty acid epoxides. The fractionation of plant raw materials and residues is another way of directly utilizing nature's synthesis potential. At Fraunhofer IGB, these pretreatment methods are (further) developed and, if necessary, further conditioning and functionalization are added.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB