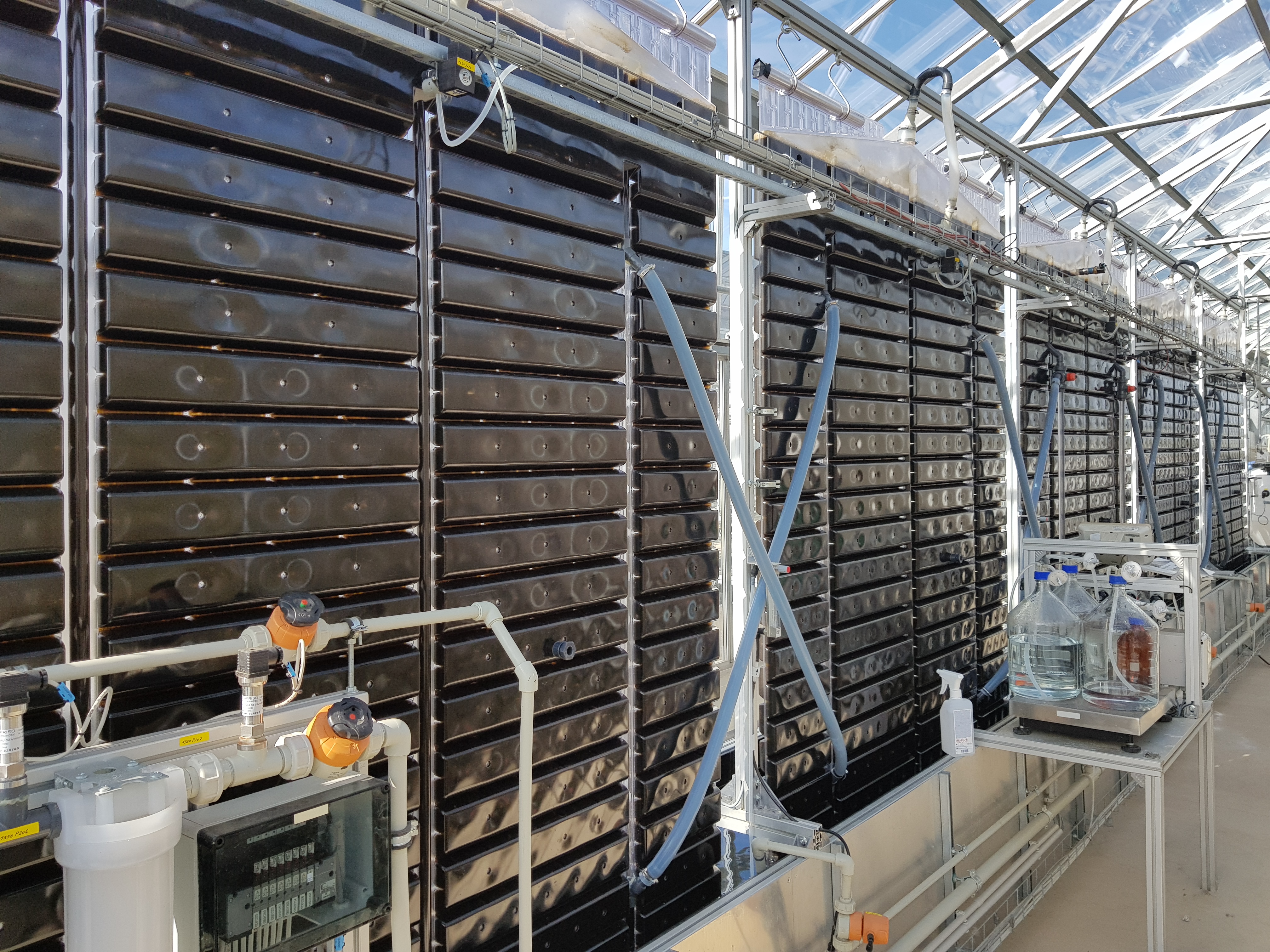

Microalgae can be grown in closed cultivation systems called photobioreactors. In addition to light and carbon dioxide (CO2), these single-celled organisms need nutrients such as nitrogen and phosphorus to grow. Microalgae biomass can contain various valuable compounds. Which ones are produced and in what concentrations depends on the cultivation conditions, e.g., the nutrient supply, and – above all – the choice of microalgae species. Various algae species can be used to produce pigments, omega-3 fatty acids or proteins that are suitable for use in the food or cosmetic industry.

In the FuTuReS research project funded by the German Federal Ministry of Food and Agriculture (BMEL), researchers from Fraunhofer IGB, the University of Hohenheim and the Karlsruhe Institute of Technology (KIT) investigated under which conditions and for which applications the cultivation of microalgae is currently already economically viable in Germany.

The intended evaluation is based on existing, empirical process data. It should take into account not only potential value‑added chains for the use of recycling and nutrient‑rich streams of residual materials, such as nitrogen, phosphate, and CO2, but also the supply of surplus electricity from biogas and photovoltaic plants in agriculture. Especially when there is a lack of light, e.g., at night, the excess energy can be used in particular for additional artificial illumination to significantly increase biomass productivity in photobioreactors.

Process data from microalgae production and extraction of valuable compounds

Therefore different pilot-scale cultivation scenarios were compared for the first time: cultivation of microalgae in photobioreactors outdoors or in greenhouses using sunlight versus indoor cultivation in photobioreactors using artificial illumination. For this comparison, the single-celled diatom Phaeodactylum tricornutum, which can also be grown effectively under central European climatic conditions, was used. Its high EPA, fucoxanthin, and protein content ensures a very high added overall value. Therefore, the research focused on the production of the pigment fucoxanthin, eicosapentaenoic acid (an omega-3 fatty acid, abbreviated to EPA) and proteins, as well as the associated value creation.

Higher biomass yield with artificial lighting

The process data generated by the cultivation processes was used in a techno-economic analysis and life-cycle assessment conducted at the University of Hohenheim. The results revealed that, in Germany, continuous artificial lighting with energy-saving LEDs offers advantages over outdoor cultivation using sunlight (which, of course, is not continuous) .

Regarding the produced valuable compounds, the researchers were able to show that cultivating microalgae to obtain high-cost products such as fucoxanthin and EPA can be an economically worthwhile pursuit. However, no further increase in profitability can be achieved by additionally extracting proteins because proteins are already globally available at relatively low prices.

Lower costs through automation

The results of the project directly affected the further work of the working group at Fraunhofer IGB. Reducing the costs of microalgae cultivation, e.g., by automating processes or introducing new lighting and reactor concepts, remains in its focus. Furthermore, we are looking for partners who are interested in putting the research results into practice outside of the research context.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB