Recovery of algal products with supercritical fluids

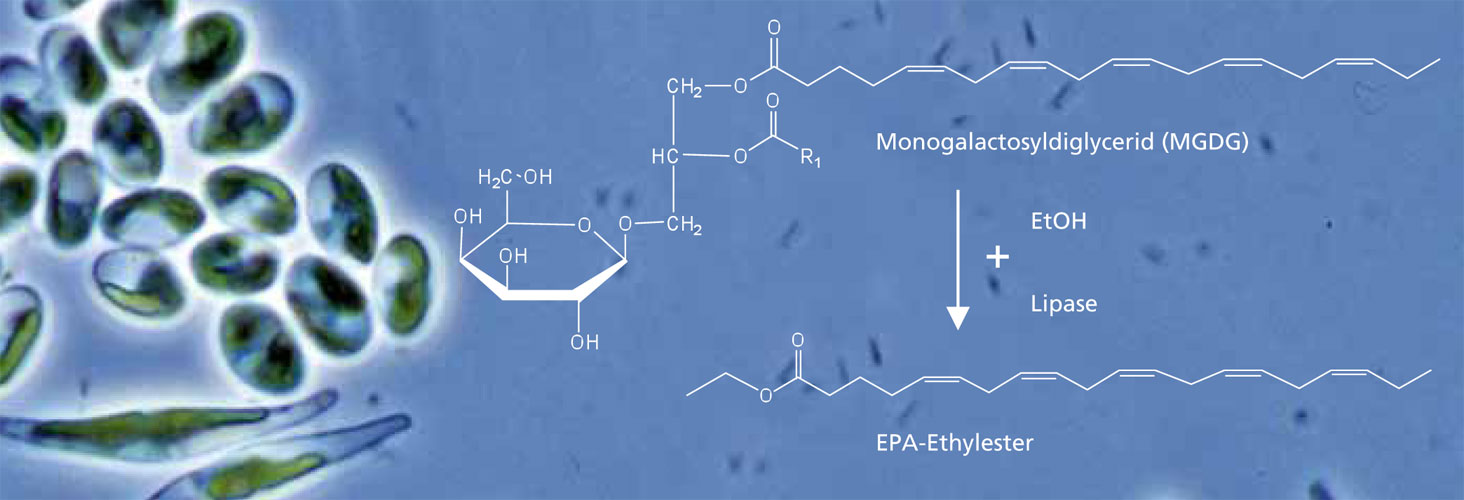

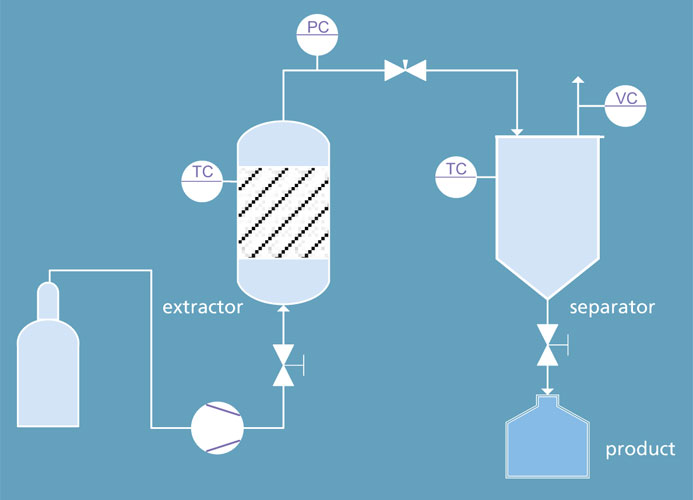

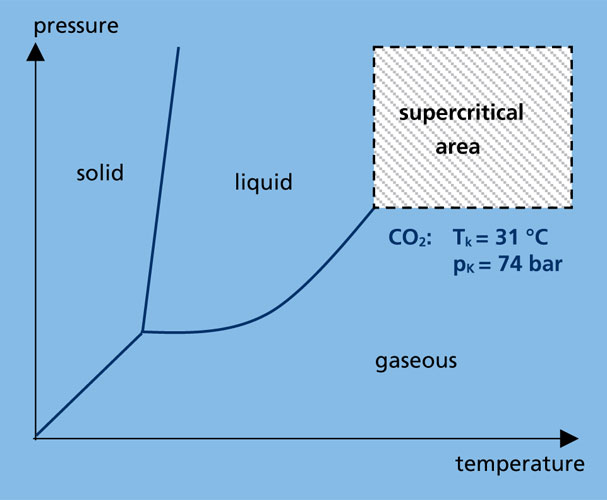

Supercritical fluid extraction, a “natural and green” way of achieving product extraction, has received increased attention as an important alternative to conventional separation methods because it is simpler, faster, more efficient and avoids the consumption of large amounts of organic solvents, which are often expensive and potentially harmful. Within a project funded by the Deutsche Bundesstiftung Umwelt (DBU) a process for the recovery of polyunsaturated omega-3-fatty acids (eicosapentaenoic acid EPA; 20:5 n-3) will be developed. Depending on the algae strain, galactolipids can be extracted with ethanol from the biomass. Using transesterification, the fatty acid esters can be purified by means of supercritical CO2. So far, cell disruption is not necessary for the strain Phaeodactylum tricornutum. In order to keep the process economical without any drying step requiring high energy consumption it is also possible to use wet biomass. Furthermore, in the next step it will be necessary to study the transesterification of the galactolipids.

EPA from Phaeodactylum tricornutum – alternative to EPA from fish oil

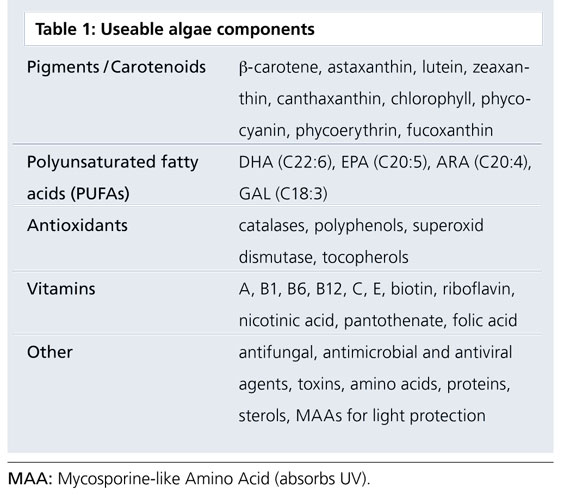

Algae produce a multitude of chemical base materials with high added value potential, such as carotenoids, fatty acids and proteins (Table ). The long-chain omega-3 fatty acid eicosapentaenoic acid (EPA, 20:5) is most often utilized as a dietary supplement. Thus far, EPA has been predominantly extracted from fish oil, where it exists in composite form with DHA (docosahexaenoic acid, 22:6). Further refinement to obtain pure EPA is a complex and expensive process. Due to the various effects of both of these fatty acids on the human body, only pure fatty acids are capable of a precise and definite application. In comparison to fish oil, many microalgae hold only EPA (ca. 5 percent by weight) along with shorter-chain fatty acids and no DHA. The goal of an ongoing project at the Institute for Interfacial Engineering IGVT at the University of Stuttgart is therefore to establish an integrated process for the production of EPA from the microalgae Phaeodactylum tricornutum as a cost-effective alternative to EPA production from fish oil.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB