Pulping

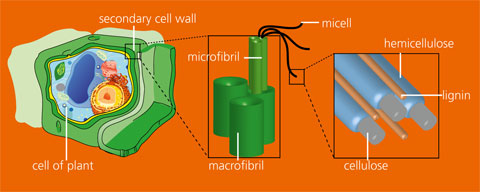

Due to its compact structure and high lignin content, lignocellulose is very resistant to enzymatic attack, in contrast to sugar- and starch-based raw materials such as sugar beet and potatoes. For this reason, suitable pulping methods are required for lignocellulose-based raw materials in order to ensure optimum coupling utilization of these biogenic raw materials. The digestion effectively separates the components lignin (aromatic compounds), cellulose (C6 sugar) and hemicellulose (C5 sugar) and makes them available for industrial use.

There are many different digestion principles that can be divided into physical, physicochemical, chemical and biological processes. Of particular interest here are the so-called organosolv processes, which comprise a large number of processes that use either organic acids, alcohols or aromatics as solvents in combination with water. Alcohols, especially low-molecular alcohols, are the organic solvents most frequently used in organosolv processes, as they ensure a more energy-efficient recovery. Which conditions and chemicals are used in the organosolv process depends on the regenerative raw material source used and the desired target products.

The digestion of lignocellulose usually produces two streams of valuable substances: firstly, the cellulose-containing fibre, which can subsequently be hydrolyzed to glucose by cellulolytic enzymes (fibre hydrolysate), and secondly, a liquid digestion solution. This digestion solution contains dissolved hemicellulose sugar and dissolved lignin. Once the lignin has been separated by precipitation, these components can also be recycled separately.

Saccharification

By digestion, lignocellulose, as described above, is converted into the material streams cellulose fiber and the supernatant of the digestion solution (hemicellulose). In the next step, the monomeric sugars are obtained from cellulose or hemicellulose by enzymatic treatment. Enzyme complexes are used for this purpose, which work together synergistically in order to achieve an optimum sugar yield. Cellulases break down cellulose into the glucose units it contains, hemicellulases release the sugars contained in hemicellulose, mainly xylose.

Another effect of the digestion is the change in the crystallinity of the remaining cellulose fraction and an increase in the specific surface area of the fiber particles. This facilitates the adsorption of the enzymes and thus increases the yield. Furthermore, the even distribution of the hydrolytic enzymes by sufficient mixing of the pulp mass is of great importance for an optimal space-time yield of the hydrolysis process. The Fraunhofer IGB has developed a powerful stirred reactor system that is suitable for mixing fiber pulp with up to 30 percent solids content due to its special stirrer geometry. Yields of > 100 g/kg glucose were achieved. In this way a complete hydrolysis and thus a holistic use of the cellulose fraction can be guaranteed.

Recycling of the individual fractions

The fractions obtained are suitable for various applications. The glucose-containing fiber hydrolysate can be used by a large number of microorganisms as a substrate in fermentations. After lignin precipitation and enzymatic cleavage of the contained sugar oligomers, the hemicellulose-rich digestion solution can be used for the fermentation of microorganisms in addition to the fiber hydrolysate. Through the chosen digestion method, the fractions may contain toxic degradation products of lignocellulose such as furfural or hydroxymethyl-furfural, which can impair the growth of microorganisms.

Detoxification methods can be used to increase fermentability for such organisms. To this end, we have established an enzymatic detoxification process at the Fraunhofer IGB. A laccase of Trametes versicolor was immobilized and the minimum enzyme concentration required to remove > 80 percent of the aromatic substances from the solution was determined. It has also been shown that no laccase mediator is required for this process. The remaining toxic substances can then be removed from the fractions, e.g. by adsorption on carrier materials.

Lignin is the largest natural, regenerative source of raw materials for aromatic compounds. A material-industrial use of lignin requires a conversion of the raw material to suitable biosynthetic building blocks, which in turn can be polymerized to polyurethane or other plastics.

Various organisms are known for the natural degradation of wood and lignin-containing biomass. These are insects, white rot fungi and bacteria. These organisms produce different enzyme cocktails which are needed to degrade the complex structure of lignin. So far there is no large-scale biotechnological process for lignin degradation and modification. An essential prerequisite for the future use of biotechnological, ecological processes for the efficient utilisation of lignin is the availability of efficient and stable biocatalysts.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB